All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel pipes support the transportation of chemicals in the semiconductor manufacturing industry?

Steel pipes support the transportation of chemicals in the semiconductor manufacturing industry due to their durability, resistance to corrosion, and ability to handle high pressure. These pipes prevent leaks and contamination, ensuring the safe and efficient transfer of chemicals throughout the manufacturing process.

How do you ensure the proper alignment and orientation of steel pipe joints during installation in critical systems?

To ensure the proper alignment and orientation of steel pipe joints during installation in critical systems, several steps can be taken. Firstly, meticulous planning and measurement should be undertaken, ensuring accurate alignment and orientation before the installation process begins. Additionally, the use of alignment tools and fixtures can aid in achieving precise positioning of the pipe joints. Regular monitoring and inspections throughout the installation process are also crucial to identify any misalignments or deviations early on and make necessary adjustments promptly. Lastly, trained and experienced personnel, following industry best practices, should be involved in the installation to ensure the proper alignment and orientation of steel pipe joints in critical systems.

How are steel pipes used in the manufacturing of kitchen appliances and fixtures?

Steel pipes are used in the manufacturing of kitchen appliances and fixtures as they provide a strong and durable structural component. These pipes are commonly used for creating the framework and support structures in appliances such as refrigerators, ovens, and dishwashers. Additionally, steel pipes are utilized in the plumbing systems of kitchen fixtures like sinks and faucets, ensuring proper water flow and drainage.

How are steel pipes manufactured?

Steel pipes are manufactured through a process called seamless or welded pipe manufacturing. In the seamless process, a solid steel billet is heated and pierced to form a hollow tube, which is then rolled and stretched to the desired size and shape. Welded pipes, on the other hand, are made by rolling a steel plate into a cylindrical shape and then welding the edges together. Both methods involve various stages of heating, shaping, and finishing to produce durable and reliable steel pipes.

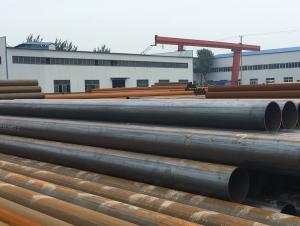

Wholesale Steel Pipes from supplier in Tuvalu

Whether you are in need of steel pipes for construction, infrastructure, or any other industry in Tuvalu, we have you covered. Our wide range of steel pipes includes various sizes, grades, and specifications to meet your specific requirements.

Our sales team is dedicated to providing exceptional customer service and assisting you throughout the entire procurement process. We can help you with product selection, pricing, and delivery options to ensure a seamless purchasing experience.

When it comes to quotations, we offer competitive pricing based on market trends and industry standards. Our team will work closely with you to understand your project needs and provide accurate and timely quotations.

In addition to sales and quotations, we also offer technical support to help you choose the right steel pipes for your applications. Our experienced engineers are available to answer any technical questions and provide guidance on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement solutions, including sourcing, logistics, and after-sales support.

With our years of market experience in Tuvalu, we have developed valuable insights and expertise that can benefit your projects. Whether you are working on a small-scale construction project or a large infrastructure development, we can provide the right steel pipe solutions tailored to your needs.

Contact us today to learn more about our steel pipe products and services in Tuvalu. Our team is ready to assist you and ensure your project's success.

Our sales team is dedicated to providing exceptional customer service and assisting you throughout the entire procurement process. We can help you with product selection, pricing, and delivery options to ensure a seamless purchasing experience.

When it comes to quotations, we offer competitive pricing based on market trends and industry standards. Our team will work closely with you to understand your project needs and provide accurate and timely quotations.

In addition to sales and quotations, we also offer technical support to help you choose the right steel pipes for your applications. Our experienced engineers are available to answer any technical questions and provide guidance on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement solutions, including sourcing, logistics, and after-sales support.

With our years of market experience in Tuvalu, we have developed valuable insights and expertise that can benefit your projects. Whether you are working on a small-scale construction project or a large infrastructure development, we can provide the right steel pipe solutions tailored to your needs.

Contact us today to learn more about our steel pipe products and services in Tuvalu. Our team is ready to assist you and ensure your project's success.