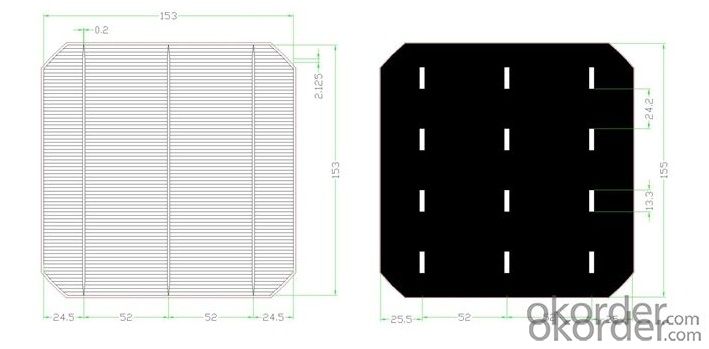

6 Inch Multi Solar Cell -- 156 x 156 mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

6 Inch Multi Solar Cell -- 156 x 156 mm

FEATURES

`Long Service Life

`High Efficiency Solar Cells

`Special Aluminum Frame Design

`High Transmission, Low Iron Tempered Glass

`Advanced Cell Encapsulation

Solar Module Specifications

Mono 80W—100W

Module | Type (36 Series) | |||||

Encapsulation | Glass/EVA/Cells/EVA/TPT | |||||

Parameters | SNM-M80(36) | SNM-M85(36) | SNM-M90(36) | SNM-M95(36) | SNM-M100(36) | |

Max power | Pm(W) | 80W | 85W | 90W | 95W | 100W |

Tolerance | +/-3% | |||||

Open circuit voltage | Voc(V) | 21.2 | 21.8 | 21.8 | 22.3 | 22.6 |

Short circuit current | Isc(A) | 4.84 | 5.00 | 5.30 | 5.44 | 5.68 |

Max. power voltage | Vmp(V) | 17.5 | 18.0 | 18.0 | 18.5 | 18.5 |

Max. power current | Imp(A) | 4.57 | 4.72 | 5.00 | 5.14 | 5.40 |

Dimensions | (L*W*H) | 1200x540x35mm | ||||

Net Weight | (kg) | 9 | ||||

Max. system voltage | (V) | 1000VDC | ||||

Operate Temp. Scope | -40/+85'C | |||||

Resistance | 227g steel ball fall down from 1m height and 120m/s wind | |||||

Warranty | Pm is no less 90% in 10 years and no less 80% in 25 years | |||||

STC | (Standard Test Condition: 1000W/m2, AM1.5, and 25'C) | |||||

Picture show

- Q:How do solar silicon wafers contribute to reducing the risk of power outages?

- Solar silicon wafers contribute to reducing the risk of power outages by harnessing sunlight and converting it into electricity. These wafers are the key component of solar panels, which can be installed on rooftops or large-scale solar farms. By generating renewable energy, solar silicon wafers provide an alternative source of power that is independent of traditional electricity grids. This diversification of energy sources helps to reduce the strain on existing power infrastructure and decreases the likelihood of blackouts or power outages during peak demand periods.

- Q:4 inch polished silicon wafer thickness of 250um, after polishing the thickness of 6 inches of 300um, the current use of wax free polishing process often fragments, to find a solution!

- The wax free polishing template can ensure the free rotation of the silicon wafer in the groove of the template,

- Q:How are solar silicon wafers affected by temperature gradients?

- Solar silicon wafers are indeed affected by temperature gradients. When there is a temperature difference across the wafer, it can cause stress and strain within the material. This can lead to the development of cracks or even the complete failure of the wafer. To minimize these effects, manufacturers often use techniques like thermal annealing or doping with specific materials to enhance the wafer's thermal stability.

- Q:How is the purity of a solar silicon wafer measured?

- The purity of a solar silicon wafer is typically measured through various techniques, such as resistivity and impurity concentration measurements. Resistivity is commonly used as an indicator of purity, with higher resistivity indicating higher purity. Impurity concentrations, such as those of boron, phosphorus, and other elements, are also assessed to determine the level of impurities in the silicon wafer. These measurements help ensure the quality and efficiency of the solar cells fabricated from the wafer.

- Q:Can solar silicon wafers be used in solar-powered telecommunications systems?

- Yes, solar silicon wafers can be used in solar-powered telecommunications systems. These wafers are a key component of solar panels used to capture sunlight and convert it into electricity. Solar-powered telecommunications systems can utilize solar panels to generate the required electrical power for various communication devices and equipment, making them more environmentally friendly and sustainable.

- Q:What is the role of rear surface passivation in solar silicon wafers?

- The role of rear surface passivation in solar silicon wafers is to minimize the recombination of charge carriers at the rear surface, thereby improving the efficiency of the solar cell. This passivation layer helps to reduce the losses caused by electron-hole recombination at the rear surface of the wafer, allowing more charge carriers to reach the front surface and contribute to the current generation.

- Q:What are the different materials used for backsheets in solar silicon wafers?

- The different materials commonly used for backsheets in solar silicon wafers include Tedlar (polyvinyl fluoride), TPT (Tedlar/polyester/Tedlar), PVF (polyvinyl fluoride), and PET (polyethylene terephthalate).

- Q:What is the role of surface recombination velocity on solar silicon wafers?

- The surface recombination velocity plays a crucial role in determining the efficiency and performance of solar silicon wafers. It represents the rate at which charge carriers recombine at the surface of the wafer, thus limiting their ability to contribute to power generation. A low surface recombination velocity is desirable as it allows more charge carriers to reach the contacts and be collected, resulting in higher conversion efficiency. On the other hand, a high surface recombination velocity leads to increased recombination losses and reduced overall performance of the solar cell. Therefore, minimizing surface recombination velocity is essential for optimizing the efficiency and output of solar silicon wafers.

- Q:How are solar silicon wafers protected from static electricity damage?

- Solar silicon wafers are protected from static electricity damage through various measures such as grounding the equipment and personnel, using anti-static packaging materials, employing ionization techniques to neutralize static charges, and implementing proper handling procedures to minimize the risk of electrostatic discharge.

- Q:How are solar silicon wafers protected from electrical faults or short circuits?

- Solar silicon wafers are protected from electrical faults or short circuits through the implementation of various protective measures. One common method is the use of anti-reflective coatings on the surface of the wafers, which not only enhance their efficiency but also act as a protective layer. Additionally, they are typically encapsulated within a durable, non-conductive material, such as glass or a polymer, to provide insulation and safeguard against electrical faults. Furthermore, electrical connections and circuits within the solar panels are carefully designed and installed to minimize the risk of short circuits and ensure proper functioning of the system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

6 Inch Multi Solar Cell -- 156 x 156 mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords