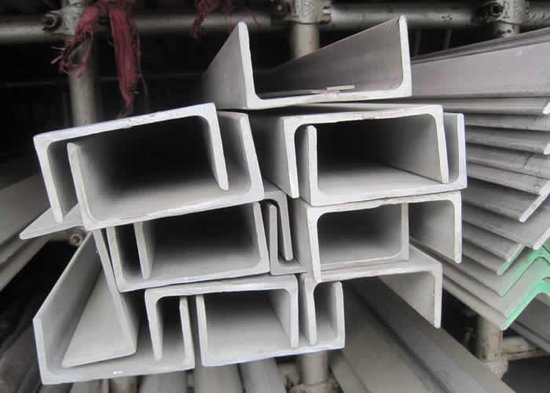

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channels

Stainless Steel Channel, is ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Channel has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments

The standard length for most size channel is 12’-14’ random lengths, but lengths are available in some sizes up to 20’ and longer. Finishes on channel can vary and include cold drawn, centerless ground, smooth turned, rough turned, turned ground and polished, and HRAP.

· We will custom saw cut to length

· DEFARS or domestic material available in many sizes

· Polishing services are available

|

Product Name |

Stainless Steel Channel | |

|

Standard |

JIS, ASTM, GB, DIN, EN, AISI | |

|

Grade |

301,302,303,304,304L,305,309S,310S,316,316L,317,317L,321,347 631... | |

|

Diameter |

75x30x6mm many other sizes can be done | |

|

Length |

1m~6m |

|

|

Package Detail |

Export standard package, bundled or be required. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM | |

|

Delivery Time |

Normally according to the order quantity or upon negotiation | |

|

Payment Terms |

L/C, T/T | |

|

Application |

Food stuff, gas, metallurgy, biology, electron, chemical, petroleum, boilers, nuclear, energy, construction field, ships building industry, war and electricity industry, boiler heat exchanger, machiner and hardware fields and medical equipment, fertilizer, etc.

| |

|

Contact |

Our products are very popular because of high-quality and reasonable prices. If you are interested in any of our products, please feel free to contact us for more information. | |

- Q:How do stainless steel channels contribute to indoor air quality in buildings?

- Stainless steel channels play a significant role in improving indoor air quality in buildings. They contribute to air quality by reducing the presence of harmful pollutants and allergens in the indoor environment. One way stainless steel channels contribute to indoor air quality is through their corrosion resistance. Stainless steel is highly resistant to corrosion and does not react with air or moisture, preventing the release of harmful particles or gases into the air. This is particularly important in buildings where moisture and humidity levels may be high, as it helps to prevent the growth of mold, mildew, and bacteria which can negatively impact air quality. Additionally, stainless steel channels are easy to clean and maintain. They have a smooth surface that does not accumulate dirt, dust, or other contaminants, making them ideal for areas that require frequent cleaning or are prone to high levels of dust accumulation. By keeping these areas clean, stainless steel channels help to prevent the buildup of allergens and pollutants, improving the overall indoor air quality. Furthermore, stainless steel channels are non-porous and do not absorb or emit odors, ensuring that unpleasant smells do not linger in the indoor environment. This is particularly beneficial in areas such as kitchens or bathrooms where odors from cooking or waste can be a concern. By minimizing odors, stainless steel channels contribute to a fresher and more pleasant indoor air quality. Overall, stainless steel channels contribute to indoor air quality in buildings by their corrosion resistance, ease of cleaning, non-porous nature, and lack of odor absorption. By reducing the presence of harmful pollutants, allergens, and odors, stainless steel channels help to create a healthier and more comfortable indoor environment for building occupants.

- Q:How do stainless steel channels contribute to energy-efficient lighting systems?

- Stainless steel channels play a crucial role in contributing to energy-efficient lighting systems. These channels, often used as housing or supports for lighting fixtures, offer several benefits that enhance the efficiency of lighting systems. Firstly, stainless steel is highly durable and resistant to corrosion, making it a long-lasting material for lighting channels. This durability ensures that the lighting system remains intact and functional for an extended period, reducing the need for frequent replacements or repairs. By minimizing maintenance requirements, stainless steel channels contribute to energy efficiency by reducing downtime and increasing the overall lifespan of the lighting system. Additionally, stainless steel channels can be designed to optimize light distribution and minimize wastage. Through precise engineering and fabrication, these channels can be shaped to direct light in the desired direction, eliminating unnecessary spillage or scatter. By channeling the light effectively, stainless steel channels maximize the efficiency of the lighting system, ensuring that the generated light is utilized to its fullest potential. Moreover, stainless steel channels can be designed to incorporate reflective surfaces or coatings that enhance the efficiency of the lighting system. These reflective elements help redirect and amplify the light output, improving the overall brightness and illumination. By increasing the effectiveness of the lighting, stainless steel channels reduce the energy consumption required to achieve the desired level of brightness, resulting in energy savings. Furthermore, stainless steel channels offer thermal management properties that contribute to energy-efficient lighting systems. Excessive heat generation can significantly reduce the lifespan and efficiency of lighting fixtures. Stainless steel channels act as heat sinks, efficiently dissipating heat away from the lighting fixtures, thereby preventing overheating and ensuring optimal performance. This thermal management feature extends the lifespan of the lighting system, reducing the need for frequent replacements and minimizing energy consumption. In summary, stainless steel channels contribute to energy-efficient lighting systems by providing durability, optimizing light distribution, incorporating reflective surfaces, and offering thermal management properties. These channels enhance the overall efficiency, lifespan, and performance of lighting systems, resulting in reduced energy consumption and increased sustainability.

- Q:Are stainless steel channels suitable for the construction of support beams?

- Indeed, support beams can indeed be constructed using stainless steel channels. Thanks to its remarkable durability, strength, and resistance to corrosion, stainless steel proves to be an exceptional option for structural purposes. The standardized shape of stainless steel channels facilitates their seamless integration into diverse construction undertakings, rendering them highly manageable. Moreover, they offer exemplary support and exhibit the ability to endure substantial loads, thereby making them an ideal selection for support beams in buildings, bridges, and various infrastructure ventures. Furthermore, stainless steel boasts a sleek and contemporary aesthetic, making it a favored preference in architectural designs.

- Q:Are stainless steel channels resistant to staining?

- Yes, stainless steel channels are highly resistant to staining.

- Q:What are the different types of stainless steel finishes available for channels?

- There are several different types of stainless steel finishes available for channels, including brushed, mirror, satin, and mill finishes.

- Q:Can stainless steel channels be painted or coated for additional protection?

- Stainless steel channels have the capability to undergo painting or coating in order to enhance their protection. Despite being renowned for its resistance to corrosion, the application of paint or coating on the channels can further safeguard against various environmental elements, such as moisture, chemicals, or UV radiation. By creating a barrier between the stainless steel surface and potential corrosive agents, the paint or coating extends the lifespan of the channels and elevates their aesthetic appeal. Moreover, painting or coating stainless steel channels enables them to blend seamlessly with the surrounding environment or be easily identified through color-coding for specific applications. It is crucial to meticulously select a paint or coating that is compatible with stainless steel and to adequately prepare the surface before applying the protective layer to ensure optimal adhesion and longevity.

- Q:Can stainless steel channels be used in swimming pool or water treatment applications?

- Stainless steel channels are indeed suitable for swimming pool or water treatment applications. Due to its exceptional resistance to corrosion, stainless steel is an excellent option for environments that come in contact with water and chemicals. In swimming pools, stainless steel channels are frequently utilized to offer structural reinforcement for the pool walls, while also providing a polished and pristine appearance. In water treatment settings, stainless steel channels serve a multitude of functions, including supporting filters, transporting water or chemicals, and establishing efficient drainage systems. The reliability, durability, and corrosion resistance of stainless steel make it an enduring and dependable material for these particular purposes.

- Q:Are stainless steel channels resistant to graffiti or vandalism?

- Yes, stainless steel channels are highly resistant to graffiti or vandalism. Stainless steel is a durable and robust material known for its corrosion resistance and strength. It is also non-porous, making it difficult for graffiti to adhere to its surface. Additionally, stainless steel has a smooth finish, which makes it easier to clean and remove any graffiti that may occur. This characteristic reduces the chances of graffiti artists targeting stainless steel channels. Moreover, stainless steel is resistant to scratches and dents, making it less susceptible to vandalism. Overall, stainless steel channels are an excellent choice for areas prone to graffiti or vandalism, as they offer long-lasting protection and are relatively easy to maintain.

- Q:How is stainless steel channel manufactured?

- Stainless steel channels are produced by either hot rolling or cold drawing. When using the hot rolling technique, a stainless steel billet is heated to a high temperature and then fed through a series of rollers that apply pressure. This pressure shapes the billet into the desired channel form. After cooling, the channel is cut to the required length. On the other hand, the cold drawing method involves first heating the stainless steel billet to a lower temperature, making it more malleable. It is then passed through one or multiple dies that gradually decrease the billet's diameter, resulting in the desired channel shape. This process is repeated until the desired dimensions are achieved. Both the hot rolling and cold drawing processes yield a smooth and even surface finish, although cold drawing generally produces a higher precision product. Once the stainless steel channel is manufactured, it may undergo additional processes such as polishing, grinding, or coating to enhance its appearance or improve its resistance to corrosion.

- Q:Are stainless steel channels suitable for industrial applications?

- Industrial applications can utilize stainless steel channels as they possess the necessary qualities for these settings. Stainless steel is renowned for its durability, strength, and resistance to corrosion, making it an ideal material for various industrial purposes. Industries such as construction, manufacturing, and transportation commonly employ stainless steel channels. Within the construction industry, stainless steel channels find frequent use for structural support in buildings and bridges. These channels are resistant to corrosion, ensuring their ability to withstand harsh environmental conditions, including moisture, chemicals, and extreme temperatures. In the manufacturing sector, stainless steel channels are employed to create robust and dependable machinery and equipment. They can be utilized for material conveyance, support of heavy loads, or the formation of structural components. The strength of stainless steel channels allows them to endure rigorous industrial processes, ensuring their longevity and reliable performance. Moreover, stainless steel channels are well-suited for industrial applications in the transportation sector. They are commonly used in the construction of vehicles such as trucks, trains, and ships. Stainless steel's resistance to corrosion and its high strength-to-weight ratio make it an excellent choice for components that need to withstand the demanding conditions of transportation. In conclusion, stainless steel channels are an excellent choice for industrial applications due to their durability, resistance to corrosion, and strength. They provide reliable support and structural integrity across various industries, making them a preferred option for industrial projects.

1. Manufacturer Overview |

|

|---|---|

| Location | Qingdao,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Middle East;Europe;North America |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.8 |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords