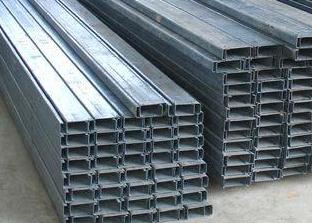

Prime Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q:What are the different corrosion resistance levels for stainless steel channels?

- Stainless steel channels, which are widely used in various industries, offer varying levels of corrosion resistance. The corrosion resistance of stainless steel is mainly determined by its composition, with the addition of specific alloying elements playing a crucial role. There are several grades of stainless steel channels, each with different corrosion resistance levels: 1. Austenitic stainless steel channels: This type of stainless steel, such as grade 304 or 316, is the most common and widely used due to its excellent corrosion resistance. It contains high amounts of chromium and nickel, which form a protective passive layer on the surface, preventing corrosion from occurring. 2. Ferritic stainless steel channels: These grades, including 430 and 446, offer good resistance to atmospheric corrosion and some chemicals. However, they are less resistant to chloride-induced corrosion compared to austenitic stainless steels. 3. Martensitic stainless steel channels: This type, such as grade 410, has moderate corrosion resistance and is mainly used in applications where high strength and hardness are required. However, it is more prone to corrosion than austenitic or ferritic stainless steels. 4. Duplex stainless steel channels: Duplex grades, such as 2205 and 2507, possess superior corrosion resistance due to their dual-phase microstructure of austenite and ferrite. They excel in highly corrosive environments, such as marine or chemical applications, offering a good balance between strength and corrosion resistance. It is important to note that the corrosion resistance of stainless steel channels can be further enhanced through surface treatments, such as passivation or electropolishing, which remove contaminants and improve the formation of the protective oxide layer. Ultimately, the selection of a specific stainless steel grade for channels should be based on the environment in which it will be used and the level of corrosion resistance required. Consulting with a materials engineer or corrosion specialist can help in determining the most suitable stainless steel grade for a particular application.

- Q:Can stainless steel channels be used in structural framing?

- Yes, stainless steel channels can be used in structural framing. Stainless steel is a strong and durable material that offers excellent corrosion resistance, making it suitable for various applications including structural framing. It provides stability and strength to the structure and is often used in construction projects where longevity and resistance to environmental factors are important considerations.

- Q:Are stainless steel channels suitable for high-traffic areas or heavy-duty applications?

- Stainless steel channels prove to be highly suitable for areas with high foot traffic and heavy-duty tasks. Being a durable and corrosion-resistant material, stainless steel can endure the constant wear and tear caused by continuous foot traffic and heavy loads. Its reputation for strength and stability has made it a favored option in industrial, commercial, and public spaces. Walkways, platforms, bridges, and machinery support are just a few examples of applications where stainless steel channels can withstand heavy loads effortlessly. Moreover, stainless steel's sleek and modern appearance adds to its appeal, making it a preferred choice for areas with a high volume of people where aesthetics matter as well. All in all, stainless steel channels present themselves as a reliable and long-lasting solution for any high-traffic or heavy-duty situation.

- Q:Can stainless steel channels be used for staircase or handrail systems?

- Certainly, staircase or handrail systems can indeed utilize stainless steel channels. The durability, corrosion resistance, and aesthetic appeal of stainless steel make it a favored option for such systems. Stainless steel channels ensure a secure and steadfast structure, guaranteeing safety and long-lasting usage. Moreover, stainless steel is effortlessly cleaned and maintained, rendering it a practical selection for heavily frequented areas like staircases and handrails. In conclusion, stainless steel channels present a dependable and fashionable alternative for staircase and handrail systems.

- Q:Can stainless steel channels be used for walkway grating systems?

- Yes, stainless steel channels can be used for walkway grating systems.

- Q:What are the design considerations for using stainless steel channels in architectural projects?

- When using stainless steel channels in architectural projects, it is important to consider several key design aspects. Firstly, stainless steel channels are highly durable and resistant to corrosion, rust, and staining. This makes them suitable for outdoor applications or areas with high moisture content, as they will maintain their structural integrity and appearance over time. Secondly, stainless steel channels have a sleek and modern aesthetic that can enhance the overall design of architectural projects. Their clean and reflective surface complements various design styles, and they can seamlessly blend with other materials like glass or wood, creating a visually appealing and cohesive look. Thirdly, stainless steel channels offer superior strength and stability, making them suitable for structural applications. They have a high load-bearing capacity, which is ideal for supporting heavy materials such as glass panels or concrete slabs. This ensures the safety and longevity of the architectural project. Moreover, stainless steel channels are relatively low maintenance compared to other materials. They are easy to clean and require minimal upkeep, with regular cleaning using mild soap and water being sufficient. This practicality makes them a practical choice for architectural projects. Furthermore, stainless steel is a sustainable material as it is 100% recyclable. By choosing stainless steel channels for architectural projects, one can contribute to reducing the carbon footprint and promoting eco-friendly practices. Additionally, their excellent longevity reduces the need for frequent replacements, minimizing waste. Lastly, while stainless steel channels may have a higher upfront cost, their long-term benefits outweigh the initial investment. Their durability and low maintenance requirements result in lower repair and replacement costs over time. Furthermore, their aesthetic appeal and versatility can enhance the overall value of the architectural project. In conclusion, when incorporating stainless steel channels into architectural designs, it is important to consider their durability, aesthetic appeal, strength and stability, ease of maintenance, environmental sustainability, and cost-effectiveness. By doing so, one can achieve a visually appealing, structurally sound, and sustainable project.

- Q:How do stainless steel channels perform in high-temperature applications?

- Stainless steel channels are renowned for their outstanding performance in applications that involve high temperatures. With their high melting point and ability to resist heat, stainless steel channels can endure extreme temperatures without experiencing any notable strength or structural deterioration. The presence of chromium in stainless steel makes it highly resistant to oxidation, preventing the formation of scale or rust when exposed to intense heat. This property ensures that stainless steel channels maintain their appearance and functionality even in the most severe temperature environments. Moreover, stainless steel channels possess superb thermal conductivity, enabling them to effectively distribute and dissipate heat. This characteristic is particularly advantageous in high-temperature applications where the channels need to transfer heat away from delicate components or equipment. Additionally, stainless steel channels exhibit low thermal expansion, meaning they do not warp or deform when subjected to sudden temperature fluctuations. This ensures their dimensional stability and reliability. Furthermore, stainless steel channels offer exceptional resistance to corrosion, a critical feature in high-temperature environments where moisture, chemicals, or other corrosive agents are commonly present. They can withstand harsh conditions and maintain their structural integrity, even in aggressive chemical environments. In conclusion, stainless steel channels are an ideal choice for high-temperature applications due to their exceptional heat resistance, thermal conductivity, dimensional stability, and corrosion resistance. Whether it is in industrial furnaces, power plants, or automotive exhaust systems, stainless steel channels provide reliable and long-lasting performance in demanding high-temperature environments.

- Q:How do you determine the appropriate gauge or thickness for a stainless steel channel?

- When determining the appropriate gauge or thickness for a stainless steel channel, several factors should be considered. Firstly, the intended use of the channel is crucial. Different applications require different levels of strength and durability. For instance, if the channel will be used in a heavy-duty construction project, a thicker gauge stainless steel would be necessary to withstand the weight and pressure. On the other hand, if the channel is for a light-duty application, a thinner gauge may be sufficient. Secondly, the dimensions and size of the channel should be taken into account. A larger channel may require a thicker gauge to provide stability and prevent bending or warping. Conversely, smaller channels may not require as much thickness. Additionally, the environment in which the stainless steel channel will be installed plays a significant role in determining the appropriate gauge. If the channel will be exposed to harsh conditions such as high humidity, extreme temperatures, or corrosive substances, a thicker gauge stainless steel with better resistance to corrosion would be necessary. Moreover, considering the weight-bearing capacity required is vital. If the channel will be used to support heavy loads or equipment, a thicker gauge stainless steel would be suitable to ensure structural integrity. Lastly, it is essential to consult industry standards and guidelines specific to the intended application. These standards provide recommendations and requirements for gauge or thickness selection, ensuring safety and compliance. In summary, determining the appropriate gauge or thickness for a stainless steel channel involves considering the intended use, dimensions, environmental conditions, weight-bearing capacity, and industry standards. Consulting with experts or professionals in the field can provide valuable insights and guidance in making the right decision.

- Q:Stainless steel tank installation, no channel base, okay?

- Yes, as long as the dirt below is flat, it can withstand the gravity of the tank.

- Q:Can stainless steel channels be used in the construction of pulp and paper mills?

- Yes, stainless steel channels can be used in the construction of pulp and paper mills. Stainless steel is a durable and corrosion-resistant material that is well-suited for the harsh and corrosive environments typically found in pulp and paper mills. It offers exceptional strength, longevity, and resistance to chemicals, making it a suitable choice for various applications within the industry.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b)Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prime Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords