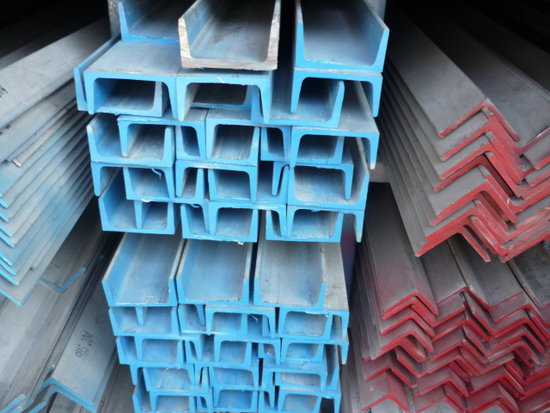

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q:Are stainless steel channels suitable for pharmaceutical or medical applications?

- Indeed, stainless steel channels prove to be a fitting option for pharmaceutical or medical purposes. The pharmaceutical and medical sectors commonly employ stainless steel due to its exceptional resistance to corrosion, hygienic properties, and durability. Stainless steel channels offer a strong and dependable solution for various applications within these industries, including the construction of cleanrooms, equipment frames, and storage systems. The material demonstrates the ability to endure harsh cleaning agents and sterilization procedures without experiencing corrosion or contaminating the surroundings. Furthermore, stainless steel possesses a non-porous nature, rendering it immune to bacterial growth and easy to clean. These characteristics deem stainless steel channels an ideal selection for pharmaceutical or medical applications where cleanliness, hygiene, and long-term effectiveness are of utmost importance.

- Q:What are the weight limitations for stainless steel channels?

- The weight restrictions for stainless steel channels are contingent upon several factors, including the channel's size, shape, and the specific grade of stainless steel employed. In general, stainless steel channels possess robustness and are capable of bearing substantial loads, rendering them suitable for a variety of structural applications. Weight restrictions can differ significantly based on the channel's dimensions. For example, smaller stainless steel channels with narrower dimensions will have lower weight restrictions compared to larger channels with wider dimensions. Furthermore, the weight capacity of the channel is also influenced by the thickness of the stainless steel material employed in its fabrication. In addition, the choice of stainless steel grade plays a pivotal role in determining the weight restrictions of the channel. Stainless steel is available in various grades, such as 304, 316, and 316L, each possessing distinct mechanical properties. Generally, higher-grade stainless steel channels exhibit higher weight limitations due to their heightened strength and resistance to corrosion. To ascertain the weight restrictions for a specific stainless steel channel, it is advisable to refer to the manufacturer's specifications or perform engineering calculations. These resources furnish comprehensive information regarding the maximum weight and load capacity that the channel can safely sustain, guaranteeing its usage falls within its intended design limits.

- Q:How do stainless steel channels perform in low-temperature applications?

- The excellent performance of stainless steel channels in low-temperature applications is widely recognized. This is due to their unique chemical composition and properties, which enable them to exhibit exceptional toughness and durability even in extremely cold conditions. Unlike other materials, stainless steel channels have a high resistance to brittleness and do not experience significant changes in their mechanical properties when exposed to sub-zero temperatures. In low-temperature environments, stainless steel channels retain their strength and structural integrity, making them the perfect choice for a range of applications such as cryogenic storage, refrigeration systems, and cold weather construction projects. Unlike other materials, stainless steel does not become brittle or susceptible to cracking in extreme cold conditions. This characteristic ensures the safety and reliability of structures or equipment in low-temperature settings. Furthermore, stainless steel channels offer excellent corrosion resistance, which is particularly important in low-temperature applications where condensation or exposure to moisture may occur. This corrosion resistance prevents rusting and deterioration of the channels, ensuring their long lifespan and maintaining their structural integrity. To summarize, stainless steel channels excel in low-temperature applications due to their superior toughness, resistance to brittleness, and corrosion resistance. This makes them a reliable choice for a variety of industries and environments that require durability and reliability in sub-zero conditions.

- Q:What are the magnetic properties of stainless steel channels?

- Stainless steel channels are known for their typically low magnetic properties, primarily because of the abundant chromium content in stainless steel. This chromium forms a passive layer on the material's surface, ensuring exceptional resistance against corrosion. Consequently, the passive layer prevents magnetization, thus classifying stainless steel channels as non-magnetic. It is worth mentioning, however, that certain stainless steel grades may contain trace amounts of other elements like nickel or manganese, which could slightly affect the magnetic properties. Nevertheless, stainless steel channels are generally regarded as non-magnetic materials.

- Q:Can stainless steel channels be used for sports facilities?

- Yes, stainless steel channels can be used for sports facilities. Stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it an ideal choice for applications in sports facilities where strength and longevity are important factors. Additionally, stainless steel's aesthetic appeal and versatility make it suitable for various uses, such as handrails, fencing, bleachers, or equipment supports in sports facilities.

- Q:What are the acoustic damping properties of stainless steel channels?

- Stainless steel channels have good acoustic damping properties due to their dense and rigid structure, which effectively absorbs and dissipates sound energy, reducing the transmission of noise and vibrations.

- Q:How do stainless steel channels contribute to LEED points or green building certifications?

- Stainless steel channels can contribute to LEED (Leadership in Energy and Environmental Design) points or green building certifications in several ways. Firstly, stainless steel is a highly durable material with a long lifespan, reducing the need for frequent replacements and therefore minimizing waste. Additionally, stainless steel is recyclable, which means that at the end of its life cycle, it can be reused or repurposed, reducing the environmental impact. Moreover, stainless steel channels are often manufactured using sustainable practices, such as minimizing energy consumption and emissions. These factors contribute to sustainable construction practices, making stainless steel channels a favorable choice for green building certifications.

- Q:What are the different load testing methods for stainless steel channels?

- There exists a variety of load testing techniques that can be employed to assess the strength and performance of stainless steel channels. These techniques encompass: 1. Static Load Testing: This approach involves the application of a constant load to the stainless steel channel while measuring the deflection or deformation over a specified duration. Its purpose is to determine the maximum load capacity and structural integrity of the channel. 2. Dynamic Load Testing: This method entails subjecting the stainless steel channel to dynamic loads, such as vibrations or impact loads, to evaluate its ability to endure sudden or repetitive forces. It proves particularly useful in evaluating the resilience and durability of the channel under real-world conditions. 3. Fatigue Testing: Fatigue testing involves subjecting the stainless steel channel to repeated load or stress cycles to simulate the effects of long-term usage. This technique aids in determining the channel's resistance to fatigue failure and its expected lifespan. 4. Tensile Testing: Tensile testing is executed by applying an axial load to the stainless steel channel until it reaches its breaking point. This process measures the channel's ultimate tensile strength, yield strength, and elongation, furnishing valuable information regarding its mechanical properties and suitability for specific applications. 5. Shear Testing: Shear testing consists of applying a force parallel to the plane of the stainless steel channel to ascertain its shear strength. This method plays a crucial role in evaluating the channel's resistance to lateral forces and its capacity to handle load distribution. 6. Buckling Testing: Buckling testing is employed to determine the critical buckling load of the stainless steel channel. By gradually increasing loads, this technique identifies the point at which buckling occurs, enabling engineers to design structures capable of withstanding anticipated loads without failure. 7. Finite Element Analysis (FEA): While not a physical testing method, FEA is a potent simulation technique that predicts and analyzes the behavior of stainless steel channels under diverse loads. By simulating load distribution and stress patterns, FEA offers valuable insights into the channel's performance and optimization potential. It is essential to note that the choice of the appropriate load testing method relies on specific requirements, intended applications, and regulatory guidelines governing the stainless steel channel. Consulting with experts and conducting a comprehensive evaluation is vital to guarantee accurate and reliable results.

- Q:What are the different methods of surface cleaning for stainless steel channels?

- Different methods exist for cleaning stainless steel channels, each with their own advantages and considerations. The following are various approaches: 1. Using a mixture of detergent and water: The most common and basic technique for cleaning stainless steel channels involves combining a mild detergent with water to eliminate dirt, grease, and other contaminants. After employing the detergent solution, it is crucial to thoroughly rinse the channels with clean water to prevent residue. 2. Applying a vinegar solution: Vinegar, a natural and effective cleaner, proves useful in removing stains and mineral deposits from stainless steel channels. Dilute vinegar with water, apply it to the surface, and gently scrub with a soft cloth or sponge. Rinse with clean water and ensure thorough drying. 3. Utilizing a baking soda paste: Another gentle and natural cleaner for stainless steel surfaces is baking soda. Create a paste by mixing baking soda with water and apply it to the channels. Scrub the surface using a soft cloth or sponge, then rinse with clean water. This method effectively eliminates tough stains and odors. 4. Employing a stainless steel cleaner: Several commercial stainless steel cleaners, specifically designed for cleaning and polishing stainless steel surfaces, are available in the market. These cleaners come in spray or liquid form and can be directly applied to the channels. For optimal results, follow the manufacturer's instructions. 5. Utilizing steam cleaning: Steam cleaning is an environmentally friendly and powerful method for cleaning stainless steel channels. It involves using high-pressure steam to eliminate dirt, grime, and bacteria from the surface. Both commercial and residential steam cleaners are available, and they effectively sanitize the channels without the need for chemicals. 6. Polishing the channels: Polishing stainless steel channels aids in restoring their shine and removing minor scratches. Various stainless steel polishes and polisher kits are accessible for buffing the channels. Apply the polish with a soft cloth, rub it in a circular motion, remove any excess, and buff the channels to achieve a shine. It is essential to note that when cleaning stainless steel channels, it is recommended to first test the cleaning method on a small, inconspicuous area to ensure no damage occurs. Additionally, abrasive cleaners, brushes, and steel wool should be avoided, as they can scratch the stainless steel surface.

- Q:How do I calculate the load capacity of a stainless steel channel?

- To calculate the load capacity of a stainless steel channel, you will need to consider several factors. First, you need to determine the cross-sectional area of the channel. This can be done by measuring the width, height, and thickness of the channel. Multiply the width and height to get the cross-sectional area. Next, you need to determine the yield strength of the stainless steel being used. This information can usually be obtained from the manufacturer or by referring to material specification standards. The yield strength represents the maximum stress that the stainless steel can withstand before it permanently deforms. Once you have the cross-sectional area and yield strength, you can calculate the load capacity by multiplying the cross-sectional area by the yield strength. This will give you the maximum load that the stainless steel channel can support without experiencing permanent deformation. It is important to note that this calculation provides an estimate of the load capacity, and additional factors such as the length of the channel, the type of loading (uniform or point load), and the type of support or fixings used should also be considered. For more accurate calculations, it is recommended to consult with a structural engineer or reference applicable design codes and standards.

1. Manufacturer Overview |

|

|---|---|

| Location | Qingdao,China |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Middle East;Europe;North America |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.8 |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords