Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Made in China stainless steel chimney pipe

Our Services

We assure you:

Small MOQ + Cheap Price + Good Quality + Fast Delivery

OUR STRENGTH

1.100% Manufacturer.

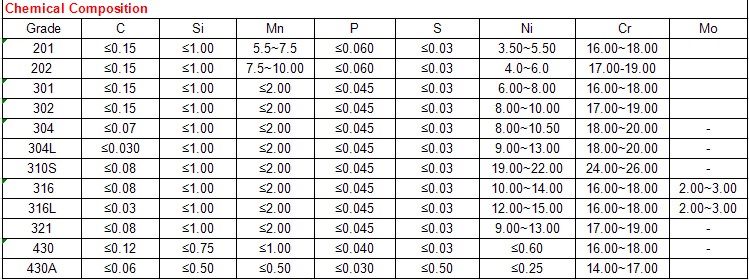

2. Specializing in processing 200 / 300 / 400 / 900 series stainless steel.

3. Well-trained and experienced staffs.

4. Able to answer all your enquiries in fluent English.

5. Russian enquiries can be well understand and replied

FAQ

1. Small quantity, short time delivery

If we have stocks, we can ship from a minimum of 1 kg sample in a few days. We also manufacture custom-order materials in amounts of 300 kg and up (Some materials are allowed 50 kg) in as few as 3 weeks.

2. High-precision thickness

We guarantee thickness tolerances that cannot be reproduced by competitors.

Example:

t <0.30mm tolerance ±1 - 3 μm guaranteed

0.30 mm≤t Tolerance ± 1% guaranteed

3. Ability to add multiple features

We are capable of adding a variety of features to metallic materials(resin coating, plating, bonding different kinds of metal, multigage skiving, etc.).

4. Unique technology and custom-made solutions

We provide customed solutions to your problems with our unique technologies and well versed knowledge of materials acquired through our experience of manufacturing 50,000 items.

5. Choose the appropriate base metals for your needs.

We carefully balance quality, delivery time and price,procure various base metals from all over the world.

We manufacture appropriate products to your needs.

6. To control metal structure(chemical formation)

We can manufacture ultrafine metal structures with a grain size of 1 μm. Using finer grain sizes provides benefits such as hardenability,balancing strength and ductility, and precision press processing.

7. Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

8. Global network

Our plant located in Japan, Shanghai and Taiwan,we also support flexibly local procurement and production transfer.

- Q:Can stainless steel pipes be used for irrigation systems?

- Indeed, irrigation systems can utilize stainless steel pipes. Stainless steel boasts exceptional corrosion resistance, rendering it a prime selection for water-related purposes. It can endure the demanding conditions inherent in irrigation systems, such as chemical exposure, fertilizers, and fluctuating temperatures. Moreover, stainless steel pipes exhibit durability and possess a lengthy lifespan, guaranteeing the irrigation system's longevity. Furthermore, they deliver superb flow rates and can withstand high-pressure water without experiencing leakage or harm. Consequently, stainless steel pipes represent a dependable and effective choice for irrigation systems.

- Q:What factory uses industrial stainless steel tube to be more?

- For equipment manufacturing and maintenance, etc., the annual consumption of stainless steel pipe more than 20000 tons. Such industries mainly use sanitary or antibacterial grade stainless steel tube.

- Q:What are the different grades of stainless steel used in pipes?

- There are several different grades of stainless steel used in pipes, including 304, 316, 321, and 409. These grades vary in their chemical composition and properties, making them suitable for different applications and environments.

- Q:Are stainless steel pipes suitable for pharmaceutical industries?

- Pharmaceutical industries find stainless steel pipes to be highly suitable. The reason is that stainless steel possesses excellent corrosion resistance and can withstand high temperatures and pressure. These qualities are essential in pharmaceutical applications, where maintaining product purity and preventing contamination are crucial. The non-reactive nature of stainless steel pipes ensures that they do not interact with the pharmaceutical products being transported. This guarantees the integrity and safety of the drugs. Additionally, stainless steel pipes are easy to clean and sanitize, making them ideal for pharmaceutical manufacturing processes that require frequent cleaning. Moreover, stainless steel pipes adhere to the strict regulations and standards set by pharmaceutical authorities. This ensures that the industry's quality and safety requirements are met. They can also be customized to meet specific needs, such as different sizes, shapes, and wall thicknesses, allowing for flexibility in design and installation. In conclusion, stainless steel pipes offer numerous advantages for pharmaceutical industries. These advantages include durability, resistance to corrosion and contamination, ease of cleaning, and compliance with industry standards.

- Q:What is the difference between inside diameter and outside diameter in stainless steel pipes?

- The inside diameter refers to the measurement of the inner space or bore of a stainless steel pipe, while the outside diameter refers to the measurement of the outer circumference or width of the pipe. Essentially, the inside diameter determines the flow capacity of the pipe, while the outside diameter determines the overall size and strength of the pipe.

- Q:What is the difference between 304LN and 316LN stainless steel pipes?

- The main difference between 304LN and 316LN stainless steel pipes lies in their composition and the addition of certain elements. 304LN stainless steel is an austenitic stainless steel that contains low carbon content and nitrogen. It is designed to provide improved strength and corrosion resistance compared to standard 304 stainless steel. The addition of nitrogen promotes the formation of a stable austenite phase, which enhances the material's mechanical properties. On the other hand, 316LN stainless steel is also an austenitic stainless steel but contains molybdenum and a higher nickel content compared to 304LN. The addition of molybdenum increases the material's resistance to pitting corrosion caused by chlorides and other aggressive environments. The higher nickel content further enhances the corrosion resistance and makes it suitable for more demanding applications, such as marine environments or chemical processing. In summary, while both 304LN and 316LN stainless steel pipes are austenitic and offer good corrosion resistance, the addition of molybdenum and higher nickel content in 316LN makes it more suitable for applications where enhanced corrosion resistance is required, especially in aggressive environments.

- Q:Can stainless steel pipes be insulated with polyethylene?

- Yes, stainless steel pipes can be insulated with polyethylene. Polyethylene is a commonly used insulation material for pipes due to its excellent thermal properties and high resistance to moisture. It provides effective insulation to prevent heat loss or gain from the pipe, which is important for applications that require temperature control. Additionally, polyethylene is lightweight, flexible, and easy to install, making it a suitable choice for insulating stainless steel pipes. However, it is essential to ensure that the polyethylene insulation is compatible with the specific type of stainless steel being used to avoid any potential chemical reactions or corrosion.

- Q:Why is the outer diameter of 1 inch galvanized pipe 33.7? And the outer diameter of one inch stainless steel pipe is 25.4

- The 1 inch galvanized pipe refers to the nominal size holes of 1 inches of water, the outer diameter is 33.7, its diameter fits a 1 inch pipe thread wire, and one inch stainless steel tube outer diameter is 25.4 that of the tube is in diameter standard specifications.

- Q:How do you calculate the wall thickness of a stainless steel pipe?

- The wall thickness of a stainless steel pipe can be calculated by subtracting the inner diameter from the outer diameter, and then dividing the result by 2.

- Q:What is the maximum length of a stainless steel pipe?

- The maximum length of a stainless steel pipe can differ based on different factors like the manufacturing process, the grade of stainless steel used, and the intended purpose. Typically, stainless steel pipes can be made in lengths varying from a few feet to several hundred feet. However, it is crucial to consider practical constraints such as transportation and installation needs, as longer lengths might present logistical obstacles. Moreover, extended pipes may experience heightened structural stress and an increased likelihood of bending or sagging. Hence, it is recommended to seek guidance from a manufacturer or supplier to ascertain the appropriate maximum length of a stainless steel pipe for a particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords