stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel welded pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q:Are stainless steel pipes suitable for construction projects?

- Yes, stainless steel pipes are highly suitable for construction projects. They offer exceptional strength, durability, and corrosion resistance, making them an ideal choice for various applications in construction, including plumbing, HVAC systems, structural supports, and more. Stainless steel pipes also have excellent aesthetic appeal and can withstand harsh environmental conditions, making them a reliable and long-lasting option for construction projects.

- Q:Are stainless steel pipes suitable for chemical refineries?

- Chemical refineries can rely on stainless steel pipes for their operations. The exceptional corrosion resistance properties of stainless steel make it the perfect choice for handling corrosive substances in these refineries. These pipes demonstrate remarkable chemical resistance, even in harsh and high-temperature environments, which is crucial during the refining process. Furthermore, stainless steel pipes possess great durability and can withstand the high-pressure conditions commonly encountered in refineries. They also exhibit high tensile strength, ensuring the safety and integrity of the entire piping system. In addition, stainless steel pipes are easy to clean and maintain, which is vital for preserving the purity and quality of the refined chemicals. All in all, stainless steel pipes provide a reliable and efficient solution for transporting chemicals in chemical refineries.

- Q:How are stainless steel pipes resistant to corrosion?

- Stainless steel pipes are resistant to corrosion due to the presence of an alloying element called chromium. Chromium forms a thin layer of chromium oxide on the surface of the steel, which acts as a protective barrier, preventing the steel from coming into direct contact with corrosive materials and environments. This oxide layer is highly durable and self-healing, providing long-term corrosion resistance to stainless steel pipes.

- Q:What are the different sizes available for stainless steel pipes?

- Stainless steel pipes are available in a wide range of sizes to cater to various industrial and residential applications. The sizes of stainless steel pipes typically depend on their nominal pipe size (NPS) or outside diameter (OD). The most common sizes for stainless steel pipes range from 1/8 inch to 48 inches in diameter. For smaller applications or plumbing systems, stainless steel pipes with NPS 1/8, 1/4, 3/8, and 1/2 are commonly used. These sizes are ideal for household plumbing, water supply lines, and low-pressure applications. As the requirements increase, larger stainless steel pipe sizes are available. Sizes such as NPS 3/4, 1, 1 1/4, 1 1/2, and 2 inches are commonly used in various industries and commercial applications. These sizes are suitable for higher-pressure applications like hydraulic systems, oil and gas pipelines, and chemical processing plants. For industrial applications that require even larger pipes, stainless steel pipes with sizes ranging from 2 1/2 inches to 48 inches in diameter are available. These large pipes are often used in heavy-duty applications such as petrochemical plants, power generation facilities, and large-scale construction projects. It's important to note that stainless steel pipes are also available in different wall thicknesses, commonly referred to as schedules. The schedule number determines the wall thickness, with higher numbers indicating thicker walls. The most common schedules for stainless steel pipes are Schedule 5, Schedule 10, Schedule 40, and Schedule 80. In summary, stainless steel pipes come in a wide range of sizes, starting from 1/8 inch and going up to 48 inches in diameter. The selection of the appropriate size depends on the specific application and the required pressure and flow requirements.

- Q:How do you prevent rusting in stainless steel pipes?

- To prevent rusting in stainless steel pipes, you can follow a few key steps. Firstly, ensure proper cleaning and maintenance of the pipes to remove any contaminants or corrosive substances. Additionally, avoid exposure to moisture by keeping the pipes dry and using appropriate sealing methods. Applying a protective coating or using corrosion-resistant materials can also help prevent rust formation. Lastly, regular inspections and prompt repairs of any damages or signs of corrosion can ensure the longevity of stainless steel pipes.

- Q:Can stainless steel pipes be coated for additional protection?

- Stainless steel pipes have the option of being coated to add extra protection. Coatings offer several advantages, including resistance to corrosion, increased durability, and an improved aesthetic appearance. The most frequently used coating for stainless steel pipes is a polymer-based coating that acts as a barrier against external elements and prevents corrosion. Additional protection can also be provided by applying other types of coatings, such as epoxy or zinc coatings, to stainless steel pipes. The choice of coating depends on the specific requirements and environmental conditions the pipes will encounter. By coating stainless steel pipes, their lifespan can be prolonged, and optimal performance can be ensured in various applications, including industrial and residential plumbing systems.

- Q:Can stainless steel pipes be used for HVAC systems?

- Yes, stainless steel pipes can be used for HVAC (Heating, Ventilation, and Air Conditioning) systems. Stainless steel is a widely used material in HVAC applications due to its durability, corrosion resistance, and high heat resistance. Stainless steel pipes are able to withstand high temperatures and pressures, making them suitable for both heating and cooling systems. Additionally, stainless steel pipes do not rust or corrode easily, which ensures a longer lifespan and minimal maintenance requirements for HVAC systems. The smooth interior surface of stainless steel pipes also allows for better airflow, which improves the efficiency of the HVAC system. Overall, stainless steel pipes are a reliable and efficient choice for HVAC installations.

- Q:What is the difference between 347 and 347H stainless steel pipes?

- The main difference between 347 and 347H stainless steel pipes lies in their carbon content. 347H has a higher carbon content which provides it with enhanced high-temperature strength and improved resistance to sensitization during welding.

- Q:Can stainless steel pipes be used for architectural applications?

- Stainless steel pipes are applicable for architectural purposes, offering a multitude of advantages. With its durability and versatility, stainless steel proves to be a reliable material. Its corrosion resistance makes it ideal for outdoor use, even in harsh weather conditions. Moreover, stainless steel pipes contribute to the aesthetic appeal of architectural designs, providing a modern and sleek look. They can be utilized for various architectural elements, including handrails, balustrades, structural supports, and decorative features. Additionally, their strength and reliability make them suitable for load-bearing applications, ensuring the safety and stability of architectural structures. Overall, stainless steel pipes are a popular choice for architectural applications due to their functionality, durability, and aesthetic appeal.

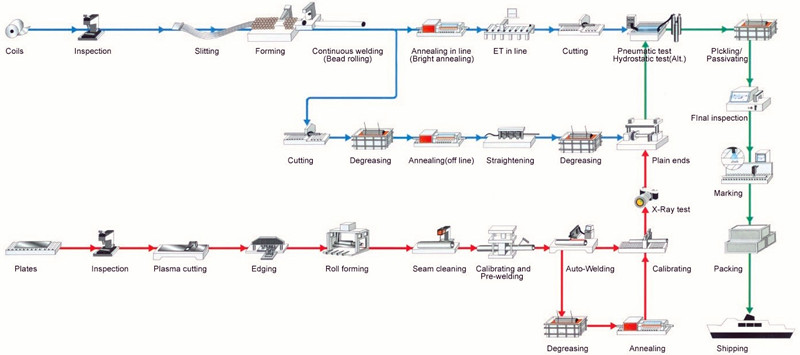

- Q:Where is the difference between seamless steel pipe and welded pipe?

- 1., the appearance of seamless steel pipe and welded pipe difference in the welded pipe wall welded tendons, and seamless No.2. seamless pipe pressure is higher, welded pipe is generally in 10 or so MPa, now welded pipe to do seamless processing.3. seamless steel tube is formed in the rolling process. Welded steel pipes need to be welded after coiling, and spiral welding and direct welding are generally used. Seamless performance is better, of course, the price is higher.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords