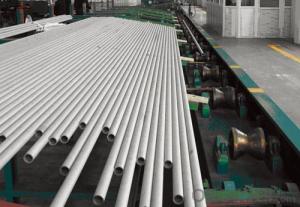

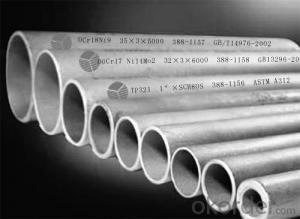

3 Inch Stainless Steel Pipe

3 Inch Stainless Steel Pipe Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For Sale3 Inch Stainless Steel Pipe Supplier & Manufacturer from China

Okorder.com is a professional 3 Inch Stainless Steel Pipe supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3 Inch Stainless Steel Pipe firm in China.Hot Products

FAQ

- Stainless steel pipes, also referred to as pipes made from stainless steel, are crafted from an alloy that is resistant to corrosion. This specific kind of steel contains a substantial amount of chromium, which creates a protective layer on the pipe's surface. This protective layer prevents the pipe from rusting or corroding. Due to their strength, durability, and ability to withstand high temperatures and pressures, stainless steel pipes are widely utilized in various industries. These industries include construction, oil and gas, chemical, and food processing. They are favored for their long lifespan and minimal maintenance needs. As a result, they have become a popular choice for plumbing systems, fluid transportation, and structural applications. Moreover, stainless steel pipes are incredibly versatile. They can be easily welded, bent, or fabricated to meet specific project requirements.

- Stainless steel tube, also known as why tube?

- Use can be divided into oil well pipe (casing, tubing and drill pipe etc.), line pipe, boiler tube, mechanical structure, hydraulic prop pipe pipe, cylinder pipe, geological pipe, chemical pipe (high pressure fertilizer pipe, oil cracking tube) and shipbuilding pipe etc.

- Stainless steel pipes and carbon steel pipes differ in several aspects, primarily in their composition, corrosion resistance, and cost. Firstly, the composition of stainless steel pipes includes a significant amount of chromium, which gives them their characteristic resistance to corrosion. On the other hand, carbon steel pipes are primarily made of iron and carbon, without any significant alloying elements. This difference in composition makes stainless steel pipes more resistant to corrosion, oxidation, and rust formation when exposed to various environmental conditions or fluids. Secondly, stainless steel pipes have excellent strength and durability due to their alloying elements, such as nickel and molybdenum, which enhance their mechanical properties. Carbon steel pipes, although strong, do not possess the same level of strength and durability as stainless steel pipes. Moreover, stainless steel pipes are highly heat resistant, making them suitable for applications involving high temperatures or extreme heat conditions. Carbon steel pipes, while having good heat resistance, may not be as effective as stainless steel in such applications. Lastly, the cost factor plays a significant role in the difference between stainless steel pipes and carbon steel pipes. Stainless steel pipes are generally more expensive than carbon steel pipes due to the higher production costs associated with their alloying elements and corrosion-resistant properties. In summary, stainless steel pipes differ from carbon steel pipes in terms of their composition, corrosion resistance, strength, heat resistance, and cost. Stainless steel pipes offer superior corrosion resistance, higher strength, and better heat resistance, making them ideal for applications in corrosive environments or high-temperature conditions. However, they come at a higher cost compared to carbon steel pipes, which are still widely used in various industries for their affordability and moderate mechanical properties.

- Why can't stainless steel be put together with carbon steel tube?

- Electrolyte: the contact area of two metals is covered with electrolyte or submerged. The iron in the carbon tube loses electrons to form ions into the solution, and the electrons on the surface of the stainless steel tubes are taken away by the corrosive agents in the electrolyte (such as oxygen in the air). Electrolytes become ionic channels.

- Yes, stainless steel pipes can be insulated with ceramic. Ceramic insulation is often used due to its excellent thermal resistance and insulation properties. It helps in reducing heat loss and conserving energy in various applications, including stainless steel pipes.

- The average lifespan of stainless steel pipes can vary depending on various factors such as the quality of the materials used, the environment in which they are installed, and the maintenance practices followed. However, on average, stainless steel pipes can last anywhere from 50 to 100 years or more with proper care and maintenance.

- Stainless steel pipes and nickel alloy pipes are both widely used in various industries for their corrosion resistance properties, high strength, and durability. However, there are some key differences between these two materials that should be considered when comparing them. One of the primary differences lies in their composition. Stainless steel pipes are primarily made of iron and chromium, with the addition of other elements such as nickel and molybdenum to enhance their corrosion resistance. On the other hand, nickel alloy pipes are predominantly made of nickel, with the addition of other elements such as chromium, iron, and molybdenum. In terms of corrosion resistance, both stainless steel and nickel alloy pipes offer excellent protection against corrosion. However, nickel alloy pipes are known to provide superior resistance to a wider range of corrosive environments, including highly acidic and alkaline conditions. This makes nickel alloy pipes more suitable for applications where extreme corrosion resistance is required, such as in chemical processing plants. Another factor to consider is the mechanical strength of the pipes. Stainless steel pipes are known for their high strength, making them suitable for applications that require structural integrity and the ability to withstand high-pressure environments. Nickel alloy pipes, on the other hand, offer even greater strength and toughness, making them ideal for applications that involve high temperatures and extreme conditions, such as in the oil and gas industry. Cost is another aspect to consider when comparing stainless steel and nickel alloy pipes. Stainless steel pipes are generally more cost-effective and widely available compared to nickel alloy pipes. Nickel alloy pipes tend to be more expensive due to the higher cost of nickel and other alloying elements used in their production. Therefore, the choice between stainless steel and nickel alloy pipes often depends on the specific requirements of the application and the budget constraints. In conclusion, stainless steel pipes and nickel alloy pipes both offer excellent corrosion resistance and mechanical strength. While stainless steel pipes are more cost-effective and widely used in various applications, nickel alloy pipes provide superior corrosion resistance and strength in extreme conditions. Therefore, the choice between these two materials depends on the specific needs and requirements of the application at hand.

- Stainless steel pipes are known for their durability and longevity, making them a popular choice in various industries and applications. The lifespan of stainless steel pipes can vary depending on several factors, including the quality of the stainless steel used, the environment in which they are installed, and the maintenance practices followed. Generally speaking, stainless steel pipes have an impressive lifespan and can last for several decades. With proper care and maintenance, they can even exceed 100 years in some cases. This is due to the inherent properties of stainless steel, such as corrosion resistance, high strength, and heat resistance. One of the primary reasons for the long lifespan of stainless steel pipes is their resistance to corrosion. Stainless steel contains a minimum of 10.5% chromium, which forms a passive oxide layer on the surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing further corrosion and ensuring the longevity of the pipe. Furthermore, stainless steel pipes can withstand extreme temperatures, making them suitable for a wide range of applications. They have excellent heat resistance, which allows them to maintain their structural integrity even under high temperatures. This property contributes to their long lifespan, as they can withstand thermal stress without degrading. Additionally, the quality of stainless steel used in the manufacturing process plays a crucial role in determining the lifespan of the pipes. Higher grades of stainless steel, such as 316 or 304, are more resistant to corrosion and have better mechanical properties. Investing in high-quality stainless steel pipes can significantly extend their lifespan. Finally, proper maintenance and regular inspections are essential for maximizing the lifespan of stainless steel pipes. Routine inspections can help identify any signs of corrosion, damage, or other issues before they escalate and cause significant problems. Regular cleaning and maintenance practices, such as removing debris or scaling, can also help prolong the lifespan of the pipes. In conclusion, stainless steel pipes have an exceptional lifespan and can last for several decades or even more than a century. Their resistance to corrosion, high strength, heat resistance, and proper maintenance practices all contribute to their long lifespan. When considering stainless steel pipes for a particular application, it is crucial to choose the appropriate grade and ensure proper care and maintenance to maximize their longevity.