Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

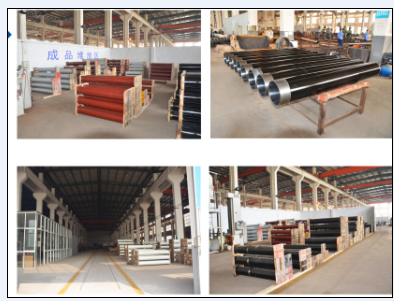

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

1. Life Span: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM

5. Material: Steel C45

6. Quenching and tempering to improve the hardness to HB241-280

7. Inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

Product Advantages:

OKorder'sConcrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN230*2100?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN230*2100?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders according to customers request?

A4: Yes, we can produce Cylinders according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q:Are there any specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts. These guidelines ensure proper installation techniques are followed to ensure the assemblies are securely and correctly installed. It is important to consult the manufacturer's instructions and adhere to industry standards to ensure optimal performance and safety of the concrete pump spare parts.

- Q:How can the concrete pump be installed and used?

- Evacuate the surrounding area while dredging the pipe. Remove pipe before cleaning should be taken to counter method, clear pipeline pressure. The pipe mouth is not allowed to disassemble

- Q:Can concrete pump spare parts be coated with anti-corrosion or anti-wear coatings?

- Yes, concrete pump spare parts can be coated with anti-corrosion or anti-wear coatings. These coatings help protect the parts from the corrosive nature of concrete or the wear and tear caused by continuous pumping. The coatings can extend the lifespan of the spare parts and improve their performance and durability.

- Q:Can I get spare parts for concrete pump boom arms and pipes?

- Yes, spare parts for concrete pump boom arms and pipes are available. Many manufacturers and suppliers offer a wide range of spare parts specifically designed for concrete pump boom arms and pipes. These spare parts can be easily found and purchased from authorized dealers or online stores. It is important to ensure that you provide accurate specifications and details of your concrete pump model to find the correct spare parts for replacement or repair.

- Q:What are the different types of concrete pump control system sensors?

- Concrete pump control systems utilize a variety of sensors to ensure smooth and efficient operation. These sensors are specifically designed to monitor different aspects of the pump's performance and provide real-time feedback to the control system. Common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors measure the concrete pressure during pumping. They are typically installed in the discharge line and are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors measure the rate at which concrete flows through the system. By monitoring the volume of concrete passing through per unit of time, these sensors enable the control system to regulate the pump's speed and output accordingly. 3. Level Sensors: Level sensors monitor the concrete level in the hopper or storage tank. They provide information about the concrete volume to prevent the pump from running dry or becoming overloaded, thus preventing pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors detect the position of moving parts in the pump system, such as the boom or outriggers. They ensure safe operation by providing feedback to the control system and preventing collisions or obstructions. 5. Temperature Sensors: Temperature sensors monitor the concrete mix temperature. They help maintain the desired temperature range during pumping, which is crucial for workability and curing. Optimal concrete temperature contributes to the quality of the final product. In summary, these sensors work in harmony to provide precise feedback to the control system, ensuring efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, these sensors optimize pumping performance and enhance productivity in concrete placement projects.

- Q:What are the indications of a malfunctioning concrete pump water pump?

- Some indications of a malfunctioning concrete pump water pump may include decreased water flow, unusual noises or vibrations coming from the pump, leaks or water pooling around the pump, and inconsistent or insufficient water pressure.

- Q:How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q:How is a concrete pump pipe different from a regular pipe?

- A concrete pump pipe is specifically designed to be used in concrete pumping applications, whereas a regular pipe is more commonly used for general plumbing purposes. Concrete pump pipes are typically made of high-quality and durable materials to withstand the high pressure and abrasive nature of pumped concrete. They also have specialized ends, such as flanges or couplings, to provide a secure connection between the pump and the delivery system. In contrast, regular pipes may come in various materials and sizes, depending on their intended use in plumbing systems.

- Q:Are there any specific safety precautions for handling concrete pump spare parts?

- Yes, there are specific safety precautions that should be followed when handling concrete pump spare parts. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and a dust mask to protect against any potential hazards. Concrete dust can be harmful if inhaled or comes into contact with the skin, so it is important to take necessary precautions. When handling concrete pump spare parts, it is crucial to ensure proper lifting techniques are used to avoid strains or injuries. Heavy parts should be lifted with the help of lifting equipment or with the assistance of others to minimize the risk of accidents. Additionally, it is important to handle the spare parts with care and avoid any rough handling or dropping, as this can lead to damage or breakage. Damaged spare parts can affect the overall performance and safety of the concrete pump. Furthermore, it is recommended to store the spare parts in a clean and dry area, away from any moisture or chemicals that could potentially damage them. Proper storage will help maintain the quality and integrity of the spare parts. Lastly, it is always advised to follow the manufacturer's instructions and guidelines when handling concrete pump spare parts. They often provide specific safety precautions and recommendations that should be followed to ensure the safe handling and use of the parts. By following these safety precautions, the risk of accidents, injuries, and damage to the concrete pump spare parts can be minimized, ensuring a safe working environment.

- Q:How do I properly maintain and replace wear plates in concrete pump spare parts?

- Proper maintenance and replacement of wear plates in concrete pump spare parts involves regular inspection, cleaning, and timely replacement. Firstly, inspect the wear plates regularly for any signs of wear, cracks, or damage. Clean them thoroughly to remove any debris or hardened concrete buildup. If the wear plates are worn out or damaged beyond repair, they should be replaced immediately to ensure optimal performance and prevent further damage to the pump. It is crucial to use high-quality replacement wear plates that are specifically designed for your concrete pump model. Following the manufacturer's guidelines and seeking professional assistance when needed will help ensure the proper maintenance and replacement of wear plates in concrete pump spare parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords