Concrete Pouring Aluminum Formwork System For Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

concrete pouring aluminum formwork system

Products Name | concrete pouring aluminum formwork system |

Specification | All size can be available. |

Using | Widely using into construction. |

Certificate | ISO9001 Approved |

Features | 1.Enhancing construction efficiency; 2.Guarantee for work safety and quality; 3.Professional mould arrangement sofeware |

Performance characteristics | 1. SAVE 30% man-hours & 50% amortized cost. 2. Easy to installation 3. Fine Brightness and Smoothness |

Resist compression | ≥ 5000kgs weight |

Resist temperature | -20°C- 60°C |

Packing | Shrink film or cartons |

Productivity | 30000 square meter/month |

Unite price/payment | FOB Tianjin |

Origin | China |

concrete pouring aluminum formwork system Advantage

1. Light weight, high strength

The data has proved that the flexural strength of aluminum is triple higher than ordinary steel.With weight of 20-25KG/M2. Aluminum formwork is the lightest formwork for construction,which makes for easy handling.

2. Various sizes, high accuracy

The construction drawing is designed with strict structure, with little measurement error and high accuracy,which is very suitable for high rise buildings.

3. Safe and convenient construction

High loading capacity requires less use of props, reducing lost in material and labor. Workers can independently operate after simple training.

4. Long time used

With the lowest average lost, aluminum formworks can be used up to 300 times.

5. Wide range used

The precise-designed formwork system applies to all kinds of building elements, such as the main wall, column, beams, stairs and balconies.

6. Excellent quality

The concrete surface is very smooth, so it can saved the swing cost and shorten the construction period.

7. High efficiency

According to different climatic conditions, the formworks can be removed in 18-36 hours.

8. Recyclable value

The used aluminum material is of greater recyclable value,several times higher than steel.

9. Independent support system

The gap between the formwork support is totally enough for passing, moving and pulling.

10. Dependable safety, environmental

The construction process is totally safe. Full aluminum structure leads to no galvanization and thus minimizes the pollution to our earth

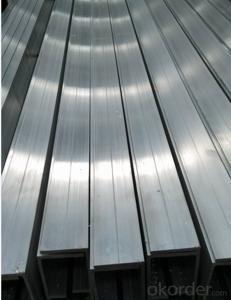

concrete pouring aluminum formwork system picture

- Q: What is the development prospect of aluminum template design?

- More than the number of turnaround, good economy: aluminum alloy template system can be used up to 300 times, each set of template system in a slight improvement can be re-used in the follow-up of new buildings, resulting in long-term low template sharing costs. Aluminum alloy template waste can be fully recycled.

- Q: In the Sheng-aluminum template installation workers, how to develop prospects

- First, it is obeying the instructions. Then, hard work hard not to suffer. Finally, either honestly go to a climb, or put you out. Solution is completed, I was Sheng through drops!

- Q: What is the change in the aluminum template?

- Aluminum template design research and development and construction applications, is a major development of the construction industry, the standard aluminum template is also in accordance with the needs of national society, to create a professional green construction, green building, environmental protection and energy conservation, efficient construction industry leading building aluminum template The

- Q: Now the domestic use of aluminum template project more?

- Traditional template construction cycle is long, dirty, chaotic, noise, resulting in a large number of construction waste, building materials, resource consumption, high labor costs, and the construction quality is difficult to guarantee. Compared to the traditional construction methods, the use of aluminum alloy template floor can be a whole casting molding, flatness and verticality better, smooth surface plastering, and can be reused more than 200 times. This can not only save a lot of manpower, material, but also can be recycled, energy saving and environmental protection, significant economic benefits.

- Q: Whether a shear wall aluminum template and wood template can be mixed

- Summary: It is recommended to use a combination of two templates in a shear wall. When the number of templates is insufficient, you can use a template alone, but it will be better than the mix.

- Q: Aluminum template of the aluminum template advantage characteristics

- Standard, versatility. Aluminum template specifications, according to the project using different specifications of sheet metal assembly; use of the template to transform a new building, just replace the 20 or so non-standard board, can reduce costs.

Send your message to us

Concrete Pouring Aluminum Formwork System For Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords