Color Coated Aluminum Coils Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction:

1 | Alloy: | A1100, A1050, A1060,A3003, A3004, A3005, A3105 , A5052, , A5754, A8011 etc. |

2 | Temper: | H14, H16, H18, H24 etc. |

3 | Thickness: | 0.2mm - 2.0mm |

4 | Width: | 15mm - 1600mm |

5 | Color: | chromic,white,metallic and so on(Customized, choose from RAL color chart or refer to customers' counter sample.) |

6 | Coating: | Polyester(mainly),Fluorocarbon(mainly), polyurethane and epoxy coating ect. |

7 | Coating thickness: | PVDF≥25 micron; PE≥18 micron. |

8 | Surface Quality: | be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

9 | Mechanical Property: | Chemical Composite and Mechanical Property are meted with GB/T, ASTM, ENAW Standard. |

10 | Interior diameter: | 105mm or 405mm or 505mm |

11 | Coating hardness: | (pencil hardness) more than 2H |

12 | Impact resistance: | no cracking and peeling(≥50kg/cm) |

13 | Flexibility(T-bend) : | ≤ 2T |

14 | MEK resistance: | more than 100 |

18 | Application: | roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden

pallets, waterproof paper and plastic coverage or or

as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

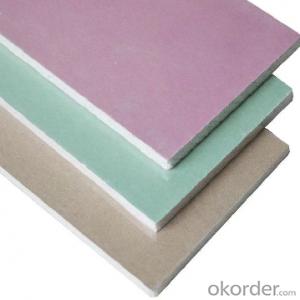

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q:im taking avelox antibiotic for my thorat bacterial infection....i brought guava juice today but i think it contains magnesium or aluminum....how long after taking avelox can i drink the guava juice????

- call a pharmacist

- Q:What are the different protective film options for aluminum coils?

- Aluminum coils have a range of protective film options available, each with its own benefits and suitability for different applications. Some commonly used options include: 1. PVC Film: These films are highly resistant to moisture, chemicals, and abrasion, making them a popular choice for protecting aluminum coils. They offer excellent surface protection and come in various thicknesses and adhesive strengths. 2. PE Film: Another popular choice, PE films provide good resistance to moisture and UV radiation. They are generally more cost-effective than PVC films and are available in different grades, such as LDPE and LLDPE. 3. PP Film: Known for their tear resistance and high tensile strength, PP films are ideal for applications where coils may undergo rough handling or transportation. They offer good protection against mechanical damage. 4. PET Film: PET films offer exceptional clarity and transparency, making them perfect for applications that require visual inspection of the coils. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings can be used to protect aluminum coils. These coatings are directly applied to the coil's surface and create a protective layer against moisture, corrosion, and scratching. When choosing a protective film for aluminum coils, it is crucial to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Seeking guidance from a supplier or manufacturer can help determine the most suitable option for specific requirements.

- Q:How are aluminum coils used in packaging?

- Aluminum coils are commonly used in packaging as they can be easily molded into different shapes and sizes. They are used to create various packaging products such as cans, containers, and foils. The coils are converted into sheets or strips, which are then formed into the desired packaging structures through processes like rolling, cutting, and shaping. The lightweight and corrosion-resistant nature of aluminum make it an ideal choice for packaging applications, ensuring the protection and preservation of various products.

- Q:Are there any specific installation requirements for aluminum coils?

- Aluminum coils have specific installation requirements that must be taken into account. When installing these coils, several factors need to be considered. First and foremost, it is crucial to provide adequate support and secure the coils properly during installation. Due to their weight, it is essential to prevent sagging or damage by using appropriate brackets or support structures. This ensures that the coils are firmly mounted. Secondly, the location and environment of the installation should be carefully assessed. Aluminum coils are commonly used in HVAC systems, so it is important to ensure that the installation area is free from any corrosive substances or chemicals that could harm the coils. Additionally, proper ventilation is necessary to prevent the accumulation of heat or moisture, as these factors can affect the coils' performance and lifespan. Moreover, it is imperative to adhere to the manufacturer's guidelines and recommendations for installation. These guidelines may include specific instructions regarding the type of fasteners or connectors to be used, the appropriate spacing between coils, and any other particular requirements for the specific aluminum coil being installed. By following these guidelines, the coils' optimal performance and longevity can be ensured. Lastly, it is highly advisable to enlist the services of a professional with experience in handling and installing aluminum coils. This will minimize the risk of any issues or damage resulting from incorrect installation. In conclusion, specific installation requirements for aluminum coils encompass proper support, consideration of the installation environment, adherence to manufacturer guidelines, and professional installation. By following these requirements, the optimal performance and longevity of aluminum coils can be achieved.

- Q:Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that is often used in the construction of modern furniture. It offers durability, resistance to corrosion, and can be easily molded into various shapes and designs. Additionally, aluminum coils can be coated or finished in different colors and textures to enhance the aesthetic appeal of the furniture.

- Q:How do aluminum coils contribute to lightweight transportation?

- Aluminum coils contribute to lightweight transportation by providing a lighter alternative to traditional materials like steel. Due to its low density and high strength-to-weight ratio, aluminum is used to manufacture various components in transportation vehicles, including coils for heating and cooling systems. The use of aluminum coils reduces the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions.

- Q:Can aluminum coils be used for sound insulation?

- No, aluminum coils are not typically used for sound insulation as they do not possess the necessary properties to effectively reduce or block sound transmission.

- Q:Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are typically restrictions on the coil thickness of aluminum coils. The specific restrictions may vary depending on the intended application and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired final product. Thinner coils are often preferred for applications that require flexibility, such as in the manufacturing of foils or flexible packaging materials. On the other hand, thicker coils are commonly used in industries like construction or automotive, where strength and durability are important factors. Additionally, the thickness of aluminum coils may be restricted by the availability and cost of raw materials. It is important for manufacturers to adhere to these restrictions to ensure the quality and performance of the final product.

- Q:Can aluminum coils be used in automotive suspension systems?

- Automotive suspension systems can utilize aluminum coils. Aluminum, a lightweight and sturdy material, provides numerous advantages for suspension components. Its high strength-to-weight ratio allows it to handle heavy loads without burdening the vehicle with unnecessary weight. This can enhance fuel efficiency and overall performance. Furthermore, aluminum is resistant to corrosion, making it particularly valuable for automotive suspension systems exposed to harsh weather conditions and road debris. By incorporating aluminum coils, manufacturers can ensure that suspension components have a longer lifespan and require less maintenance. In addition, aluminum coils possess superior heat absorption and dissipation capabilities compared to materials like steel. This aids in preventing overheating and mitigating the risk of suspension failure, especially during intense driving conditions or off-road usage. However, it is important to note that the use of aluminum coils in automotive suspension systems may entail certain compromises. Although aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must meticulously design and engineer the suspension system to ensure it can withstand necessary loads and provide sufficient support and stability for the vehicle. In summary, aluminum coils can be effectively employed in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. Nevertheless, manufacturers must carefully consider the specific requirements and trade-offs associated with aluminum usage in suspension components to ensure optimal performance and safety.

- Q:My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- i have tom deo. and it is totally safe, it is all organic stuff that you could like grow in your backyard. As apposed to chemical junk. kudoos to you for stopping with the anti-perspirants

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminum Coils Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords