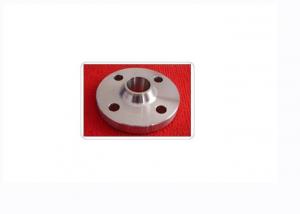

ANSI WN Carbon Steel Flange B16.5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons pc

- Supply Capability:

- 400 Tons per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

The main materials of flanges are carbon steel, stainless steel and alloy steel. The production base area is about 82300 square meters. Our annual production capacity is more than 9000 tons, with perfect detection means and quality .

Our company has passed Rhine, Germany(TUV) ISO9001 Quality Management System Certfication, European Pressure Equipment and Materials AD2000-W0 Certification. Meanwhile, we also passed the Pressure Pipe Components Manufacturing Safety Registered Certification of the State Quality Inspection Administration. All of these are a more effective guatantee for the quality of products. At the same time, our products are exported to Europe, United States, the Middle East, Africa, South-East Asia regions and other countries.

1. Type: plate flange, welding neck flange, slip-on flange, socket welding, lap joint flange, thread flange, blind flange

2. Material: carbon steel and stainless steel

3. Standard: ANSI, JIS, BS, DIN, EN, UNI, GB, and API

4. Size: OD up to 3000mm

5. Pressure: 75bls to 2500 bls

6. Marking: Required

7. Painting: yellow, blank, clear, oil and Zn

8. Inspection: in-house and the third party

- Q:Are flanges and bushings the same thing?

- Flanges and bushings are not the same thing.Turn left and turn right |Flanges (Flange), also called flanges, flanges, or flanges. A flange is a part that is connected between the pipe and the pipe, used for the connection between the ends of the pipe. It is also used for the flange on the entrance and exit of the equipment. It is used for the connection between the two devices, such as the reducer flange. Flange connection or flange joint means that the flange, the shim and the bolt are mutually connected as a group of three detachable sealing structures. Pipe flanges are flanges used for piping in pipe installations. They are used on equipment and refer to the entrance and exit flanges of the equipment. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Sub threaded flange connection (threaded connection), flange welding flange and flange clamp. Flanges are used in pairs. Low pressure pipes can be made of wire flanges and welded flanges with pressures of more than four kilograms. Add a gasket between the two flanges and secure with bolts. Different pressure flange thickness is different, they use the bolt is also different. Water pump and valve, and in the pipe connection, these equipment parts of the equipment also made corresponding flange shape, also known as flange connection. Any connecting parts that are bolted and closed in the vicinity of the two planes are generally referred to as flanges, such as the connections of the ventilation ducts, which can be called flanges". However, this connection is only part of a device, such as flanges and pumps connected, it is not good to call the water pump flange parts". Relatively small, such as valves, can be called flanges".The sleeve is a cylindrical mechanical part that is attached to the shaft. It is a part of the sliding bearing.Generally speaking, the axle sleeve and the bearing seat adopt the interference fit, and the shaft and the gap fit.

- Q:What does the flange mean? What does "flange" mean?

- Flanges (Flange) are also called flanges or flanges. The flange is the part that connects the pipe to the pipe and is connected to the end of the pipe. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Flange, threaded connection (wire), flange and welding flange.

- Q:I've heard that the ultra short flange distance can help micro transfer more lenses. What's the principle? Why is the long distance SLR not the advantage? What does the flange distance decide?

- The average flange distance refers to the distance between the metal ring on the camera body and the lens, which is in contact with the lens, to the imaging medium (photosensitive element or negative plate),This distance is longer, plus the transfer ring is longer, the focus is not easy, to the imaging medium, that is, with the transfer ring, can not focus.And the distance between the flanges is short, and the adapter ring will not be too long.

- Q:1. building fire pipe, valve, flange installation is set sixth books, or sets of eighth booksHere is the Shanxi 05 installation 7 Book notes:Three. The following contents shall be subject to other corresponding quotas:2. fire engineering valves, flanges, making all kinds of casing installation, stainless steel pipe and pipe fittings, pipe fittings and pump and pipeline installation, pipeline system strength test and tightness test and flushing executed sixth copies "industrial pipeline project" the corresponding quota.3. fire hydrant pipes, outdoor water supply pipes and water tank production, installation, implementation of eighth copies of the "water supply and drainage, heating and gas projects" corresponding projectsI would like to ask "fire engineering valve, flange installation" and "building fire pipe valve, flange installation" there is a difference between what?

- According to the national unified quota calculation rules:(1) the installation of valves, flanges, the manufacture and installation of various casings, the installation of pump rooms and pipes, the strength test of piping systems, and the tightness test, and carries out the sixth edition of the industrial pipe installation project.(2) fire hydrant pipes, outdoor water supply pipelines, installation and installation of water tanks, eighth copies of "water supply and drainage, heating and gas installation projects".(3) the installation of various fire pumps and stabilizing pumps, and the two grouting, and implements the first edition of "mechanical equipment installation works".(4) the installation of various instruments, valves with telecommunication signals, water current indicators, pressure switches, wiring, school lines, the implementation of the tenth "automatic control instrument installation project" corresponding projects.(5) all kinds of equipment support, installation, etc., the implementation of fifth copies of "static equipment and process metal structure production and installation works" corresponding projects.(6) pipeline, equipment, support, flange welding, rust, brush oil, the implementation of eleventh copies of "brush oil, anti-corrosion and insulation engineering" corresponding items.(7) system debugging, the implementation of the seventh book, the fifth chapter of the corresponding project.

- Q:The valve has a connection between the clamp and the flange. What's the difference between this and the connection?

- Flange expensive point, to clip type cheap point, should make no difference. Mainly in the demolition of the clip type pipe in the media will flow out, waste. Flange type can be closed to avoid the flow of media!

- Q:What do you mean, flange four?

- In the past, there were four carry and six carry flanges in the flange standard, which meant only the number of bolted flanges, and the number of bolts in the 4 carry flange was 4 multiples, such as: 4, 8, 16., six, and 6, 12, 18.

- Q:What is flange connection pile?

- Classification of pilesWith the development of engineering technology, new steel pile and reinforced concrete pile are more and more widely used in engineering construction. Different pile types have different characteristics.Classification according to force condition:Friction piles - most of the load is carried by the friction of the soil around the pile, while the pile at the end of the pile can be neglectedPileEnd bearing friction pile -- the pile whose load is mainly borne by the friction force of the pile bodyEnd bearing piles - most of the load is carried by the supporting force of the pile tip, while the resistance at the side of the pile is negligibleFriction end bearing pile -- the pile whose load is mainly loaded by the end of pileClassification by construction method:Mechanical hole pileBored pileImmersed tube cast-in-place pileReinforced concrete pilePile foundation, precast pile, prestressed concrete pileSteel pileCement soil mixing pileMixing pileOther chemical material mixing pilesAccording to the overall size of the pile classificationLong pilePileShort pileMiddle long stakeVariable cross-section pileAccording to the method of pile driving, prefabricated piles can be divided into driven piles, pressed piles, vibrating sinking piles, rotary piles and so on.

- Q:Is the blind flange fitted with a pair? Do I need gaskets in the middle?

- The blind plate is used to block the flange plate, such as the disc inserted short tube, one end of the connecting mouth, one does not need, you can use the blind plate on the line, block the blind plate connection needs flange rubber pad and bolt

- Q:When the toilet is fitted with flanges, is the rubber side of the flange facing the floor or the toilet? The installation is more reasonable.

- The rubber side of the flange is toward the toilet, and this has to be done by the master of water and electricity, or by the people who sell the toilet. The flanges and the toilet do not have space, but it will take some time!In addition, after the toilet is loaded, all sides should be put on glass glue, to prevent leakage of dirty gas

- Q:In the pipe installation, the three way, the elbow, the big head and the flange do not need the quota?

- In industrial pipe installation, three - way, elbow and big head should be calculated separately.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | qingda |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

ANSI WN Carbon Steel Flange B16.5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons pc

- Supply Capability:

- 400 Tons per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords