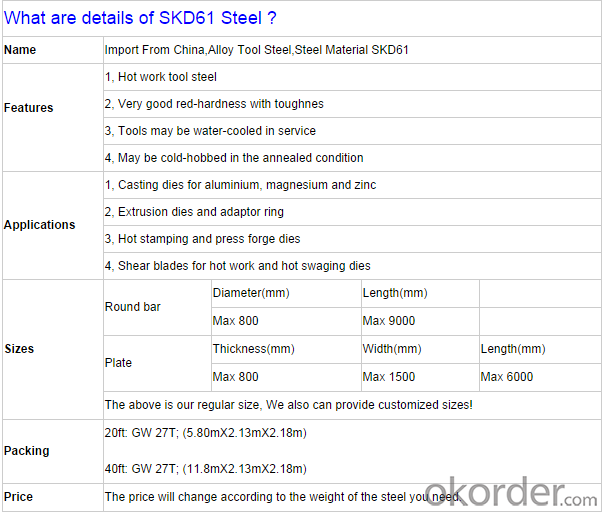

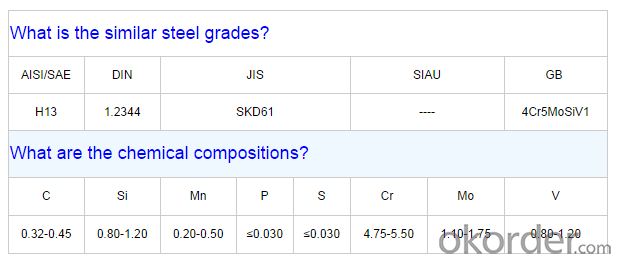

Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Type:

Alloy Steel

Shape:

Steel Round Bar

Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

Product information:

Product show

Workshop show

Our service:

- Q:How does special steel compare to other materials such as aluminum or titanium?

- Special steel boasts a unique set of advantages and characteristics when compared to materials like aluminum or titanium. Firstly, its exceptional strength and durability set it apart. With a higher tensile strength than aluminum and titanium, it is ideal for applications that require withstanding heavy loads or high-stress environments. This strength also ensures a longer lifespan by resisting wear and tear. Furthermore, special steel maintains its mechanical properties even at extreme temperatures. Unlike aluminum and titanium, which experience a significant decrease in strength at elevated temperatures, special steel retains its structural integrity, making it suitable for applications involving high temperatures or thermal cycling. In terms of cost-effectiveness, special steel often proves to be more affordable than titanium, especially in large-scale production. While aluminum is generally cheaper than special steel, it may lack the same level of strength or resistance to corrosion, limiting its applicability in certain industries. Additionally, special steel exhibits excellent machinability and can be easily formed into different shapes and sizes, allowing for greater design flexibility. This quality makes it suitable for various industries such as automotive, aerospace, construction, and manufacturing, where complex components or structures are required. Lastly, special steel showcases superior corrosion resistance compared to aluminum and titanium. It can be treated or coated to provide additional protection against rust and other forms of degradation, further extending its lifespan. In summary, special steel surpasses aluminum and titanium in terms of strength, durability, temperature resistance, and corrosion resistance. Its cost-effectiveness, machinability, and versatility make it a preferred material in various industries, where high-performance and reliability are crucial factors.

- Q:Can special steel be used for making aerospace components?

- Yes, special steel can be used for making aerospace components. Special steel, also known as aerospace steel or aircraft steel, is specifically designed to meet the high demands and stringent requirements of the aerospace industry. It possesses exceptional strength, durability, and heat resistance properties, which are crucial for withstanding the extreme conditions experienced by aircraft components during flight. Aerospace components, such as landing gear, engine parts, fasteners, and structural elements, often require materials that can maintain their integrity under high temperatures, stress, and corrosive environments. Special steel alloys are developed to have excellent mechanical properties, including high tensile strength, fracture toughness, and resistance to fatigue, creep, and corrosion. These properties make them suitable for critical aerospace applications where safety and reliability are of utmost importance. Furthermore, special steel can be tailored to specific requirements, such as weight reduction, improved fuel efficiency, and enhanced performance. Through advanced alloying techniques and heat treatments, aerospace steel can be engineered to have desirable characteristics like increased hardness, wear resistance, and dimensional stability. This allows for the production of lighter and more efficient aerospace components without compromising on strength or safety. In conclusion, special steel is a preferred material for making aerospace components due to its exceptional mechanical properties, heat resistance, and corrosion resistance. Its ability to withstand extreme conditions and be customized to specific requirements makes it an ideal choice for manufacturing critical parts used in the aerospace industry.

- Q:What are the challenges in welding special steel?

- One of the major challenges in welding special steel is its high carbon content, which can lead to the formation of brittle microstructures and increased susceptibility to cracking. Additionally, special steels often have unique alloying elements and compositions, which require precise temperature control and specialized welding techniques to maintain their desired properties. Furthermore, the presence of impurities and contaminants in special steels can cause porosity and other defects during the welding process, requiring thorough pre-weld preparation and stringent quality control measures.

- Q:What are the challenges in recycling special steel?

- One of the main challenges in recycling special steel is the complexity of its composition. Special steel often contains various alloying elements and additives that can make the recycling process more difficult. These elements need to be carefully identified and separated in order to maintain the desired properties of the recycled steel. Additionally, special steel may have undergone specific heat treatments or surface coatings, which further complicate the recycling process. Proper sorting, identification, and treatment techniques are necessary to overcome these challenges and ensure the successful recycling of special steel.

- Q:Can special steel be used in high-speed applications?

- Yes, special steel can be used in high-speed applications. Special steels such as tool steels or high-speed steels are specifically designed to withstand high temperatures, resist wear, and maintain their mechanical properties at high speeds. These steels are widely used in industries like aerospace, automotive, and manufacturing for applications like cutting tools, bearings, and gears, where high-speed performance is crucial.

- Q:How is special steel different from regular steel?

- Special steel is different from regular steel in that it is specifically formulated to possess certain enhanced properties and characteristics, such as increased strength, hardness, corrosion resistance, or heat resistance. These unique properties make special steel suitable for various specialized applications where regular steel may not meet the required specifications.

- Q:Carbon steel and stainless steel and pattern steel and special steel and high carbon steel difference

- Steel containing less than 0.25% of carbon is low carbon steel, 0. 25%-0.6% is medium carbon steel, more than 0.6% is high carbon steel, low, medium and high carbon steel can be called carbon steel, useful alloy composition is greater than 3, alloy steel

- Q:What are the challenges in manufacturing special steel?

- One major challenge in manufacturing special steel is the complex and precise process involved. Special steel requires specific chemical compositions and mechanical properties, which can be difficult to achieve consistently. Additionally, the production of special steel often involves sophisticated technologies, such as vacuum melting or controlled atmosphere furnaces, which require advanced skills and specialized equipment. Furthermore, meeting the stringent quality standards and tolerances of special steel can be demanding, as any deviation can lead to rejected batches. Overall, the challenges lie in maintaining consistent quality, meeting strict specifications, and effectively utilizing advanced manufacturing techniques.

- Q:How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through several ways. Firstly, special steel possesses enhanced strength and durability, allowing manufacturers to produce products with thinner gauges or smaller dimensions, reducing material usage and overall costs. Additionally, its superior corrosion resistance and longevity ensure that the products have a longer lifespan, reducing the need for frequent replacements. Moreover, special steel's exceptional machinability enables efficient production processes, reducing labor costs and increasing productivity. Lastly, its high precision and consistency in manufacturing contribute to minimizing defects and waste, resulting in cost savings and improved product quality. Overall, special steel's unique properties and characteristics enable manufacturers to optimize production, thereby reducing costs without compromising on product quality.

- Q:What are the main environmental impacts of special steel production?

- The main environmental impacts of special steel production include greenhouse gas emissions, air pollution, water pollution, and the depletion of natural resources. The production process involves high energy consumption, which leads to significant carbon dioxide emissions, contributing to climate change. Additionally, the use of various chemicals and additives in the process can result in air pollution, releasing toxic substances and particulate matter into the atmosphere. Moreover, the production generates wastewater and solid waste, which can contaminate water sources if not properly managed. Finally, the extraction and processing of raw materials like iron ore and coal contribute to the depletion of natural resources and habitat destruction. Overall, special steel production poses substantial environmental challenges that need to be addressed for sustainability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Tool Steel,Alloy Steel Bar Steel Material SKD61

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords