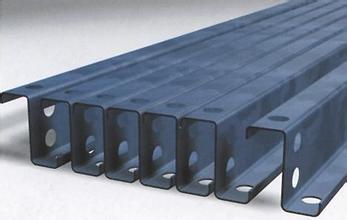

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high Quality Steel Z-Channels (Thickness: 2.0mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Quality Steel Z-Channels (Thickness: 2.0mm) are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-25 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195-Q345/SPCC

Manufacture: Cold forming

Shape: Z-channel

Dimensions:

Base: 35mm – 400mm

Width: 15mm – 25mm

Height: 80mm – 350mm

Thickness: 0.3mm – 6mm

Place of Origin: Tianjin, China

Certifications: ISO 9001:2000, TUV

Production: 20,000 tons/month

Processing Available: Threading, coupling, plastic cap protection

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel channels be used for supporting signage and billboards?

- Yes, steel channels can be used for supporting signage and billboards. Steel channels are known for their strength and durability, making them suitable for providing structural support to hold and secure various types of signage and billboards.

- Q: What are the factors to consider when selecting the right type of steel channel?

- To ensure the appropriate choice is made when selecting the right type of steel channel, several factors should be taken into consideration. These factors encompass: 1. Application type: Understanding the intended use of the steel channel is crucial. Different applications may necessitate different types of steel channels, including those used for structural support, framing, or decorative purposes. 2. Load capacity: Determining the expected load or weight that the steel channel will bear is of utmost importance. This information aids in selecting a channel with the appropriate strength and weight-bearing capacity. 3. Size and dimensions: The required size and dimensions of the steel channel should be considered. This entails the depth, width, and thickness, which should be chosen based on the specific project requirements, including the desired strength and stability. 4. Material grade: The material grade of the steel channel is vital as it determines the strength, durability, and corrosion resistance. Varied grades of steel, such as A36, A572, or A588, offer different levels of strength and suitability for diverse applications and environments. 5. Surface finish: The desired surface finish of the steel channel should be taken into account. This can range from a raw or mill finish, suitable for applications where appearance is not critical, to a galvanized or painted finish, which provides additional corrosion protection and enhances aesthetics. 6. Cost: The cost of the steel channel should be assessed in relation to the project budget. It is important to strike a balance between quality and cost-effectiveness, ensuring that the chosen steel channel meets the necessary requirements without exceeding the allocated budget. 7. Availability and lead time: The availability and lead time of the desired steel channel should be considered. This is particularly important for time-sensitive projects where quick delivery is crucial. By carefully considering these factors, one can make an informed decision when selecting the right type of steel channel. This ensures that it meets the specific project requirements and delivers optimal performance and durability.

- Q: What is the elastic modulus of steel?

- The general definition of the modulus of elasticity is that the stresses in the one-way stress state are divided by the strain in that direction.

- Q: How about the Y-Y moment of inertia in the form of hot rolled channel steel Iy?

- The method of superposition of moments of inertia: the moment of inertia of multiple rectangles plus the moment of inertia of the four surfaces of the cornersEach of the deformed moments of inertia is equal to the sum of the two triangular moments of inertia and the sectorial moments of inertiaThe sectorial moment of inertia is used in integral calculus, and the examples of advanced mathematics are taken at random.

- Q: Are steel channels suitable for high-rise construction?

- Yes, steel channels are suitable for high-rise construction. Steel channels provide structural strength, durability, and resistance to fire, making them an ideal choice for supporting heavy loads and tall structures. They can withstand the vertical and lateral forces experienced in high-rise buildings, ensuring stability and safety. Additionally, steel channels can be customized to meet specific design requirements, making them highly versatile for use in various high-rise construction applications.

- Q: What are the deflection limits for steel channels?

- The deflection limits for steel channels vary depending on several factors such as the size, shape, and material properties of the channel. However, as a general guideline, the deflection limits for steel channels typically range between L/360 to L/240, where L is the length of the channel. These limits ensure that the channel remains structurally stable and prevents excessive bending or sagging under its intended load. It is important to consult design codes and engineering standards for specific deflection limits based on the application and design requirements.

- Q: Can steel channels be used in the construction of HVAC support structures?

- Yes, steel channels can be used in the construction of HVAC support structures. Steel channels provide excellent structural support and can be easily fabricated to the required dimensions. They offer high strength and durability, making them suitable for supporting HVAC equipment such as ductwork, pipes, and air handling units. Steel channels also have the advantage of being resistant to corrosion, which is beneficial in HVAC environments where moisture and condensation are common.

- Q: Are there any specific safety considerations when working with steel channels?

- Yes, there are specific safety considerations when working with steel channels. Some of these considerations include: 1. Personal protective equipment (PPE): It is essential to wear appropriate PPE when working with steel channels, such as safety goggles, gloves, steel-toed boots, and a hard hat. This helps protect against potential hazards such as flying debris, sharp edges, and falling objects. 2. Handling and lifting: Steel channels can be heavy and cumbersome, so it is important to use proper lifting techniques and equipment to prevent strain or injury. This may include using lifting straps, slings, or cranes to safely lift and move the channels. 3. Sharp edges and corners: Steel channels often have sharp edges and corners that can cause cuts or punctures. It is important to handle them with care and use appropriate tools, such as gloves, to avoid direct contact with these sharp areas. 4. Structural stability: When working with steel channels in construction or fabrication, it is crucial to ensure the structural stability of the setup. This includes properly securing the channels in place, using appropriate support systems, and following engineering specifications to prevent collapse or accidents. 5. Fire hazards: Steel channels are highly conductive and can quickly transfer heat, making them a potential fire hazard. It is important to take precautions to prevent sparks or open flames from coming into contact with the channels, especially in environments where flammable materials are present. 6. Slips, trips, and falls: Working with steel channels can involve working at heights or on elevated surfaces. It is important to maintain good housekeeping practices, such as keeping work areas clean and clear of obstructions, using proper ladder or scaffolding systems, and using fall protection equipment when necessary to prevent slips, trips, and falls. By considering these safety precautions and following best practices, the risk of accidents and injuries can be greatly reduced when working with steel channels.

- Q: What are the standard lengths of steel channels?

- Different industries and manufacturers establish their own requirements and standards, leading to variations in the standard lengths of steel channels. However, there are commonly used standard lengths for steel channels, typically available in increments of 6 or 12 feet (1.83 or 3.66 meters). These standard lengths find widespread use in construction, manufacturing, and other sectors. Steel channels are commonly found in lengths of 20 feet (6.1 meters), 40 feet (12.2 meters), and 60 feet (18.3 meters), which are convenient for transportation, handling, and utilization in structural or fabrication projects. It is worth noting that although these are frequently encountered standard lengths, steel channels can also be custom-cut to meet the specific requirements of a given project. Additionally, regional or industry-specific standards may introduce variations in standard lengths. To obtain more precise information regarding the standard lengths of steel channels for a particular application, it is advisable to consult relevant industry standards, such as those established by organizations like the American Society for Testing and Materials (ASTM) or the American Institute of Steel Construction (AISC).

- Q: What does channel 20# mean?.

- Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used in building structures, vehicle manufacturing and other industrial structures, and channel steel is often used in conjunction with i-beam.

Send your message to us

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords