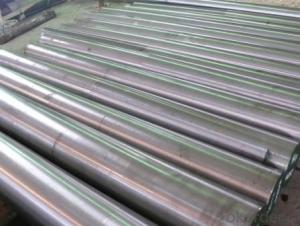

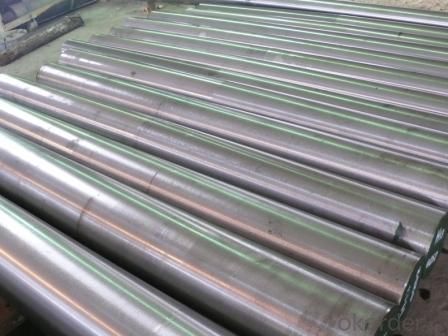

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be insulated with polyphthalamide?

- No, stainless steel pipes cannot be insulated with polyphthalamide.

- Q:Can stainless steel pipes be used for gas pipelines?

- Indeed, gas pipelines can utilize stainless steel pipes. Stainless steel, renowned for its exceptional durability and resistance to corrosion, proves to be an ideal material for transporting a wide range of gases, including natural gas and propane. Moreover, stainless steel pipes possess remarkable tensile strength, enabling them to endure the demanding conditions of high pressure and temperature frequently encountered in gas pipelines. Furthermore, stainless steel demonstrates non-reactivity, thereby guaranteeing the integrity and safety of the pipeline system by preventing any interaction with the transported gases. Ultimately, with its strength, corrosion resistance, and capability to withstand high-pressure environments, stainless steel pipes emerge as a dependable choice for gas pipelines.

- Q:What are the different grades of stainless steel used in pipes?

- Pipes commonly utilize various grades of stainless steel, each possessing distinct properties and characteristics. Notable grades include: 1. Stainless Steel Grade 304: Recognized as highly versatile and widely employed, Grade 304 exhibits non-magnetic qualities, exceptional resistance to corrosion, and ease of weldability. Its applications predominantly revolve around sectors emphasizing hygiene and cleanliness, such as food processing plants, hospitals, and the pharmaceutical industry. 2. Stainless Steel Grade 316: Renowned for its unparalleled resistance to corrosion, particularly in environments abundant in chloride or saltwater exposure, Grade 316 frequently finds utilization in marine settings, chemical processing facilities, and coastal areas necessitating robust corrosion resistance. 3. Stainless Steel Grade 321: Grade 321 boasts titanium stabilization, rendering it more impervious to sensitization and intergranular corrosion at elevated temperatures. It commonly serves in high-temperature scenarios, exemplified by exhaust systems, furnaces, and heat exchangers. 4. Stainless Steel Grade 409: Designed specifically for high-temperature applications like automotive exhaust systems, Grade 409 showcases remarkable heat resistance and exhibits low thermal expansion properties, making it an ideal choice for enduring extreme temperatures. 5. Stainless Steel Grade 904L: Grade 904L excels in corrosion resistance, particularly combating pitting and crevice corrosion. Frequently employed in aggressive environments prevalent in chemical processing plants, offshore oil and gas platforms, and pulp and paper industries. These examples merely exemplify the array of stainless steel grades employed in pipe manufacturing. The selection of a particular grade hinges upon the specific application and desired attributes, encompassing corrosion resistance, temperature resistance, and mechanical strength.

- Q:Can stainless steel pipes be used for chemical pumps?

- Yes, stainless steel pipes can be used for chemical pumps. Stainless steel is known for its excellent corrosion resistance, making it suitable for handling various chemicals. It can withstand high temperatures and pressures, ensuring reliable performance in chemically aggressive environments. Stainless steel pipes are commonly used in chemical processing industries, wastewater treatment plants, and other applications involving the transfer of corrosive liquids or gases.

- Q:Can stainless steel pipes be insulated with polypropylene?

- Indeed, polypropylene serves as an appropriate material for insulating stainless steel pipes. This is due to its remarkable thermal properties and minimal thermal conductivity. Polypropylene exhibits resistance against moisture, chemicals, and UV radiation, rendering it suitable for diverse applications. By implementing polypropylene insulation, the loss or gain of heat in stainless steel pipes can be averted, thereby enhancing energy efficiency and decreasing the likelihood of condensation or freezing. Consequently, it is imperative to guarantee the correct installation and compatibility of the polypropylene insulation with the particular stainless steel pipe in order to attain optimal performance and durability.

- Q:How do you prevent oxidation in stainless steel pipes?

- Preventing oxidation in stainless steel pipes can be achieved through several methods. One way to effectively prevent oxidation is by applying a protective coating or finish on the surface of the pipes. Various types of coatings, including paints, epoxy, or polyurethane, can serve as barriers that prevent oxygen from coming into contact with the stainless steel, thus reducing the risk of oxidation. Furthermore, keeping the pipes clean and well-maintained is crucial in preventing oxidation. It is essential to eliminate any accumulated dirt, debris, or corrosive substances from the surface of the pipes. This can be accomplished using mild detergents or specialized cleaning agents specifically designed for stainless steel. Ensuring proper ventilation in the installation area is another preventive measure. Sufficient ventilation helps minimize the presence of moisture or humidity, which can accelerate the oxidation process. Additionally, keeping the pipes dry and avoiding prolonged exposure to water or moisture is vital in preventing oxidation. Lastly, selecting the appropriate grade of stainless steel for the intended application is important. Different grades of stainless steel offer varying levels of resistance to oxidation. For instance, austenitic stainless steel grades like 304 and 316 are highly resistant to oxidation and are commonly used in applications where corrosion resistance is crucial. In conclusion, employing a combination of preventive measures, such as protective coatings, regular cleaning, proper ventilation, and selecting the appropriate stainless steel grade, can effectively prevent oxidation in stainless steel pipes.

- Q:Can stainless steel pipes be used for rainwater harvesting systems?

- Yes, stainless steel pipes can be used for rainwater harvesting systems. Stainless steel is highly resistant to corrosion, making it suitable for long-term water storage. It also ensures the water remains clean and free from contaminants, making it an ideal choice for rainwater harvesting systems.

- Q:How do stainless steel pipes compare to nickel alloy pipes?

- Both stainless steel pipes and nickel alloy pipes are widely utilized in various industries for their corrosion resistance properties, high strength, and durability. Nevertheless, there are noteworthy distinctions between these two materials that should be taken into account during comparisons. A primary difference lies in their composition. Stainless steel pipes consist mainly of iron and chromium, with additional elements like nickel and molybdenum added to enhance corrosion resistance. On the other hand, nickel alloy pipes are primarily composed of nickel, with the inclusion of other elements such as chromium, iron, and molybdenum. Regarding corrosion resistance, both stainless steel and nickel alloy pipes offer exceptional protection against corrosion. However, nickel alloy pipes are recognized for providing superior resistance to a broader range of corrosive environments, including highly acidic and alkaline conditions. This makes nickel alloy pipes more suitable for applications requiring extreme corrosion resistance, such as in chemical processing plants. Another factor to consider is the mechanical strength of the pipes. Stainless steel pipes are known for their high strength, making them suitable for applications requiring structural integrity and the ability to withstand high-pressure environments. Conversely, nickel alloy pipes offer even greater strength and toughness, making them ideal for applications involving high temperatures and extreme conditions, such as in the oil and gas industry. Cost is another aspect to consider when comparing stainless steel and nickel alloy pipes. Stainless steel pipes are generally more cost-effective and readily available compared to nickel alloy pipes. Nickel alloy pipes tend to be more expensive due to the higher cost of nickel and other alloying elements used in their production. Therefore, the choice between stainless steel and nickel alloy pipes often depends on the specific requirements of the application and budget constraints. In conclusion, both stainless steel pipes and nickel alloy pipes offer excellent corrosion resistance and mechanical strength. While stainless steel pipes are more cost-effective and commonly used in various applications, nickel alloy pipes provide superior corrosion resistance and strength in extreme conditions. Therefore, the selection between these two materials depends on the specific needs and requirements of the application at hand.

- Q:What are the common wall thicknesses for stainless steel pipes?

- The stainless steel pipes' common wall thicknesses vary based on the application and the specific grade of stainless steel used. However, there are several readily available wall thicknesses, including Schedule 5S, Schedule 10S, Schedule 40S, and Schedule 80S. Schedule 5S typically features a thinner wall thickness, making it suitable for low-pressure and light-duty applications. Schedule 10S, slightly thicker, can withstand higher pressures, making it suitable for a wider range of applications. Schedule 40S is commonly utilized in industrial and commercial settings where higher pressures and temperatures are involved. As for Schedule 80S, it boasts the thickest wall thickness and is commonly employed in heavy-duty applications like the oil and gas industry. It is crucial to note that these are just a few of the stainless steel pipe's common wall thicknesses, and other options may exist based on specific project requirements. Consulting a professional or referring to industry standards and specifications can assist in determining the appropriate wall thickness for a particular application.

- Q:What is the maximum length of a stainless steel pipe?

- The maximum length of a stainless steel pipe can vary depending on various factors such as the manufacturing process, the specific grade of stainless steel used, and the intended application. In general, stainless steel pipes can be manufactured in lengths ranging from a few feet to several hundred feet. However, it is important to consider practical limitations such as transportation and installation requirements, as longer lengths may pose logistical challenges. Additionally, longer pipes may be prone to increased structural stress and potential for bending or sagging. Therefore, it is advisable to consult with a manufacturer or supplier to determine the maximum length of a stainless steel pipe suitable for a specific application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords