Truck Mounted Concrete Pump Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Truck Mounted Concrete Pump Delivery Pipe

1. Structure of Truck Mounted Concrete Pump Delivery Pipe:

Include four types

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Truck Mounted Concrete Pump Delivery Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. Truck Mounted Concrete Pump Delivery Pipe Images:

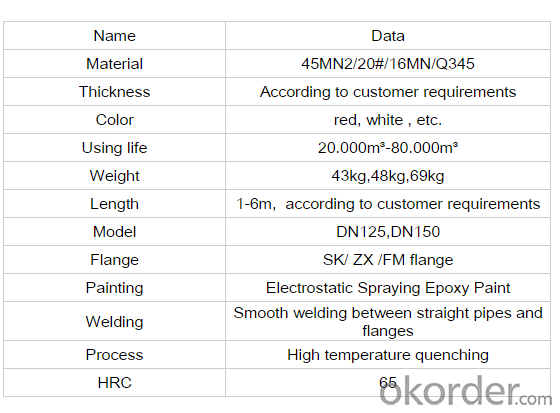

4. Truck Mounted Concrete Pump Delivery Pipe Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

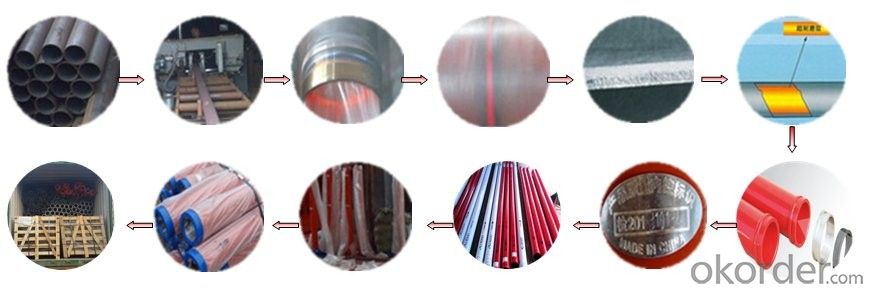

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:How can I determine if the concrete pump cylinder needs replacement?

- To determine if the concrete pump cylinder needs replacement, you can perform a few inspections and tests. 1. Visual inspection: Look for any visible signs of wear and tear on the cylinder, such as cracks, dents, or corrosion. Additionally, check for any leaks or excessive hydraulic fluid around the cylinder. 2. Performance evaluation: Pay attention to the pump's performance during operation. If you notice a decrease in pumping efficiency, irregular flow, or decreased pressure, it could indicate a problem with the cylinder. 3. Pressure testing: Conduct a pressure test to determine if the cylinder can handle the required pressure. This can be done by isolating the cylinder and pressurizing it to a level higher than what it typically experiences during operation. If the cylinder fails to maintain pressure or shows signs of leakage, it may be time for a replacement. 4. Cylinder stroke measurement: Measure the stroke length of the cylinder during operation. Uneven stroke lengths can indicate internal damage to the cylinder and may require replacement. 5. Consultation with experts: If you are unsure about the condition of the cylinder, it is advisable to consult with professionals or experts in the field. They can provide you with a more accurate assessment and recommend the appropriate course of action, which may include cylinder replacement. Keep in mind that regular maintenance and inspections are crucial for the longevity and efficient operation of the concrete pump. It is always better to address potential issues early on to avoid further damage or accidents.

- Q:Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can be retrofitted to older pump models. However, it is essential to ensure compatibility and proper installation to guarantee optimal performance and safety. Professional advice and support should be sought to ensure correct retrofitting of spare parts to older pump models.

- Q:What is the role of a concrete pump hopper grate spring?

- The primary function of a concrete pump hopper grate spring is to offer tension and support to the hopper grate within a concrete pump. It is typically crafted from robust and flexible materials like steel or rubber, and its purpose is to securely hold the hopper grate in place while allowing for necessary movement and flexibility during the concrete pumping process. By preventing the hopper grate from becoming dislodged or damaged by the force and vibrations produced by the concrete pump, the hopper grate spring proves invaluable. It guarantees that the grate remains appropriately aligned and in its proper position, facilitating a smooth and efficient flow of concrete into the pump. Moreover, the grate spring lessens the impact and stress experienced by the hopper grate, thereby enhancing its lifespan and minimizing the requirement for frequent repairs or replacements. Acting as a buffer, it absorbs and distributes the substantial forces exerted on the grate due to the weight and pressure of the concrete being pumped. In conclusion, the concrete pump hopper grate spring plays a pivotal role in preserving the integrity and functionality of the hopper grate, thereby ensuring the safe and efficient operation of the concrete pump.

- Q:Can concrete pump spare parts be inspected or certified by third-party organizations?

- Concrete pump spare parts have the potential to undergo inspection and certification from third-party organizations. These organizations are usually independent and possess the necessary knowledge and resources to assess the quality, performance, and safety of these spare parts. They adhere to industry-specific standards and guidelines while conducting inspections, tests, and audits to ascertain whether the spare parts meet the required criteria. The certification provided by these third-party organizations serves as a guarantee to customers that the spare parts have been evaluated and found to be in line with the relevant standards. This helps to foster trust and confidence in the products, ensuring their reliability and suitability for concrete pump usage.

- Q:How often should concrete pump pressure gauges be inspected and replaced?

- Concrete pump pressure gauges should be inspected and replaced on a regular basis, ideally every six months or as recommended by the manufacturer. Regular inspections help ensure accurate pressure readings and prevent potential accidents or malfunctions due to faulty gauges.

- Q:How often should hydraulic pumps be inspected or replaced in a concrete pump?

- Regular inspections of hydraulic pumps in a concrete pump are essential for maintaining their proper functioning and preventing potential problems. The frequency of these inspections depends on various factors, such as the intensity of use, operating conditions, and manufacturer's guidelines. Typically, it is advisable to inspect hydraulic pumps in a concrete pump either every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, if the pump is being used under harsh or demanding circumstances, more frequent inspections might be required. The decision to replace hydraulic pumps should be based on their condition and the recommendations provided by the manufacturer. If the pump displays significant wear and tear, leaks, reduced performance, or any other issues that cannot be resolved through maintenance or repair, it may be necessary to replace the hydraulic pump to ensure the safe and efficient operation of the concrete pump.

- Q:How do I maintain and clean concrete pump spare parts?

- To ensure the long life and smooth operation of concrete pump spare parts, it is crucial to maintain and clean them. Follow these steps to accomplish this: 1. Conduct Routine Inspections: Begin by carefully examining the spare parts for signs of wear, cracks, or damage. This step is essential for identifying potential issues that require immediate attention. 2. Apply Lubrication: To minimize friction and prevent seizing, apply lubricant to moving parts like bearings, pistons, and cylinders. 3. Thoroughly Clean: Employ a high-pressure washer or hose to thoroughly clean the spare parts. Eliminate any accumulated dirt, debris, or concrete residue, paying particular attention to hard-to-reach areas. 4. Prevent Rust: Guard metal parts against corrosion by applying a rust preventive coating. This step is especially important if the spare parts are exposed to moisture or inclement weather conditions. 5. Proper Storage: Store the spare parts in a clean and dry location to shield them from moisture, dust, and other contaminants. Avoid directly stacking them on the ground to prevent damage. 6. Regular Maintenance: Establish a maintenance schedule and adhere to it. Adhere to the manufacturer's guidelines for routine tasks such as replacing filters, checking oil levels, and inspecting seals. Regular maintenance aids in the detection of potential issues before they escalate into major problems. 7. Seek Professional Assistance: If you are uncertain about how to maintain or clean specific spare parts, it is advisable to seek professional assistance. Concrete pump spare parts are intricate and necessitate expert handling. Remember, proper maintenance and regular cleaning of concrete pump spare parts not only prolong their lifespan but also enhance the overall performance and efficiency of your concrete pump.

- Q:What are the signs of a clogged or damaged hydraulic filter?

- A clogged or damaged hydraulic filter may be indicated by several signs. One of the most common signs is a decrease in hydraulic system performance. If you observe a decrease in the speed or power of your hydraulic equipment, it may be due to a clogged filter that restricts the flow of hydraulic fluid. Another sign is an increase in heat within the hydraulic system. As the system struggles to maintain proper fluid flow and pressure, a clogged or damaged filter can cause it to overheat. Furthermore, unusual noises may be noticed coming from the hydraulic system. A clogged filter can result in air becoming trapped in the system, leading to strange noises like whining or grinding. Moreover, the presence of dirty or discolored hydraulic fluid could suggest a clogged or damaged filter. The filter's purpose is to remove dirt and contaminants from the fluid, so if it fails to do so effectively, the fluid will become dirty and discolored. Finally, frequent or recurring issues with the hydraulic system could be an indication of a clogged or damaged filter. The filter plays a critical role in maintaining the overall health of the hydraulic system, so if it is not functioning properly, it can lead to other problems such as pump failure or valve blockages. Regular inspection and replacement of hydraulic filters are crucial to ensure the proper functioning and longevity of your hydraulic system.

- Q:How can one ensure proper documentation and record-keeping for concrete pump spare parts?

- To guarantee the appropriate documentation and record-keeping for concrete pump spare parts, one can take several measures: 1. Establishing a systematic inventory management system: A well-organized inventory management system should be implemented to track all spare parts effectively. Each part should be assigned unique codes or identification numbers, and a comprehensive inventory list should be maintained. 2. Maintaining accurate records: Detailed records should be created for each spare part, including its description, quantity, purchase date, supplier information, and cost. It is crucial to update this information regularly and make it easily accessible. 3. Implementing a standardized labeling system: Clear and consistent labels should be used on all spare parts to facilitate easy identification and location. This will minimize confusion and prevent misplacement. 4. Storing spare parts in a designated area: A specific storage area should be designated for spare parts, preferably a well-organized warehouse with proper shelving and sufficient space. This ensures secure and convenient storage. 5. Implementing a maintenance and repair schedule: A maintenance and repair schedule should be developed for the concrete pump and its spare parts. Regular inspections of all parts should be conducted, and any repairs or replacements should be documented and reflected in the inventory. 6. Training staff on documentation procedures: Employees responsible for managing spare parts should receive training on proper documentation procedures. This includes accurate recording, labeling, and updating of inventory records. 7. Performing periodic stock checks: Regular stock checks should be carried out to verify the accuracy of inventory records and identify any discrepancies. This helps identify missing or misplaced spare parts and ensures up-to-date documentation. 8. Implementing an integrated software system: An inventory management software system specifically designed for this purpose should be utilized. These systems automate documentation, track stock levels, and generate reports, enhancing efficiency and accuracy. By adhering to these measures, one can ensure proper documentation and record-keeping for concrete pump spare parts, reducing the risk of errors, improving efficiency, and guaranteeing the availability of the right spare parts when needed.

- Q:Can concrete pump spare parts be coated with UV-resistant coatings for outdoor applications?

- Yes, concrete pump spare parts can be coated with UV-resistant coatings for outdoor applications. UV-resistant coatings are specifically designed to protect surfaces from the damaging effects of ultraviolet (UV) radiation, which can cause fading, cracking, and deterioration over time. By applying UV-resistant coatings to concrete pump spare parts, the parts can be safeguarded against the harmful effects of prolonged exposure to sunlight and other environmental elements. This helps to extend the lifespan of the spare parts and ensures their optimal performance in outdoor applications. Additionally, UV-resistant coatings can also provide added protection against other forms of weathering, such as moisture, temperature fluctuations, and chemical exposure. Therefore, coating concrete pump spare parts with UV-resistant coatings is a recommended practice to enhance their durability and maintain their functionality in outdoor settings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Truck Mounted Concrete Pump Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords