fiberglass cloth with vermiculite coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Fiberglass cloth coated vermiculite is a kind of high-temperature resistant products which fiberglass cloth coated by vermiculite.

Application:

Suitable for insulation for hard and soft pipe;

Thermal insulation cover,refractory shell,other insulation layer for heating machine and freezers;

Reinforcement materials for fiber reinforcement plastics like vessel,vehicle,stock tank,panel,furniture;

Movable thermal insulation cover,fireproof blanket,fireproof curtain,expansion joints and fume ductwork.It can be made into high temperature fireproof cloth and gloves which ca-n be used at high-temperature work like fireproof,stainless steel and industry;

Heat shield curtain,prevent molten liquid,welding blanket.

Product Capability:

Higher temperature resistant,thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

Higer wire resistance;

Nontoxic and harmless to the environment.

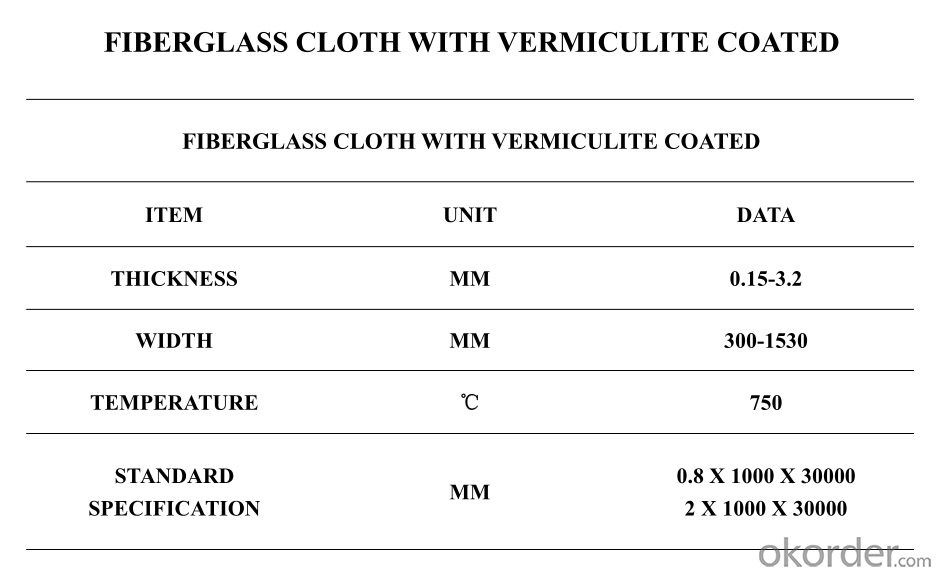

Data Sheet:

:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q:Can fiberglass fabric be used for insulation sheets?

- Yes, fiberglass fabric can be used for insulation sheets.

- Q:What is the abrasion resistance of fiberglass fabric?

- The abrasion resistance of fiberglass fabric is quite high. Due to its strong and durable nature, fiberglass fabric is known for its ability to withstand repeated friction and wear without significant damage. It is commonly used in applications where abrasion resistance is crucial, such as in the manufacturing of protective clothing, industrial curtains, and reinforcing materials for composites. The specific abrasion resistance of fiberglass fabric can vary depending on its construction, finish, and any additional coatings or treatments applied to the fabric. However, overall, fiberglass fabric is highly regarded for its excellent resistance to abrasion, making it a popular choice in industries where durability is essential.

- Q:What is an electroplated glass fabric?

- Glass fiber mesh in the process of use:The lap width between the mesh is not less than 50mm, the negative corner mesh to pressure stubble lap, its width is larger than 50mm, yang angle is greater than or equal to 200mm. In the construction, mesh paving should be smooth, no wrinkles, mortar plumpness reached 100%, at the same time to find and maintain smooth, straight corner square and the verticality of yin and yang.

- Q:How is fiberglass fabric used in the insulation industry?

- Fiberglass fabric is extensively used in the insulation industry due to its excellent thermal and acoustic insulation properties. It is commonly used as an insulating material in various applications such as residential and commercial buildings, automotive, aerospace, and industrial equipment. One of the primary uses of fiberglass fabric in insulation is in the construction industry. It is often installed in walls, floors, and ceilings to reduce heat transfer, thus improving energy efficiency and reducing heating and cooling costs. The fabric acts as a barrier, preventing the flow of heat between different areas of a building. Additionally, its ability to resist moisture absorption helps to prevent mold and mildew growth, ensuring a healthier indoor environment. Fiberglass fabric is also utilized in the insulation of pipes, ducts, and HVAC systems. It helps to maintain the desired temperature and prevent heat loss or gain during the transportation of liquids or air. This ensures efficient operation and reduces energy consumption. Furthermore, fiberglass fabric is employed in the insulation of vehicles and aircraft. It helps to minimize the transfer of heat and noise from the engine or outside environment, providing a comfortable and quiet interior for passengers. Its lightweight and flexible nature make it an ideal choice for these applications, as it can be easily molded and installed in complex shapes and tight spaces. In industrial settings, fiberglass fabric is used for insulation in equipment such as boilers, furnaces, ovens, and tanks. It helps to retain heat, ensuring efficient operation and minimizing energy loss. Additionally, fiberglass fabric is fire-resistant, which is crucial for industries that deal with high temperatures and potential fire hazards. Overall, fiberglass fabric's versatility, durability, and excellent insulating properties make it a widely used material in the insulation industry. Its ability to provide thermal and acoustic insulation, resist moisture, and withstand high temperatures make it a preferred choice for various applications, contributing to energy efficiency, environmental sustainability, and improved comfort.

- Q:Is fiberglass cloth antistatic?

- Glass fiber cloth with conductive function according to the level of application of alkali content place is not the same, for example with high alkalinity can be used as wires.

- Q:How does fiberglass fabric perform in electromagnetic fields?

- Fiberglass fabric is a good choice for shielding against electromagnetic fields due to its non-conductive properties. It can effectively block or attenuate electromagnetic waves, providing excellent protection against electromagnetic interference.

- Q:How does fiberglass fabric perform in corrosive environments in chemical plants?

- Fiberglass fabric is highly resistant to corrosion and performs exceptionally well in corrosive environments in chemical plants. Its non-reactive nature and excellent chemical resistance make it an ideal choice for protecting equipment and structures from the damaging effects of corrosive substances. Additionally, fiberglass fabric has a high tensile strength and is lightweight, making it easy to install and maintain. Overall, fiberglass fabric offers long-lasting durability and reliability in corrosive environments, ensuring the safety and efficiency of chemical plant operations.

- Q:Can fiberglass fabric be used for making speaker cones?

- Yes, fiberglass fabric can be used for making speaker cones. Fiberglass is a lightweight, rigid, and durable material that is often used in the construction of speaker cones. It offers excellent strength-to-weight ratio, which is important for maintaining the structural integrity and responsiveness of the cone. Additionally, fiberglass fabric can be molded into various shapes and sizes, allowing manufacturers to create speaker cones with different designs and performance characteristics. The material also has good acoustic properties, which contribute to the overall sound quality produced by the speaker. However, it is worth noting that the specific characteristics and performance of a speaker cone depend on various factors, including the design, materials used, and manufacturing process. Therefore, while fiberglass fabric can be used for making speaker cones, it is just one of many options available to manufacturers.

- Q:How is fiberglass fabric used in the production of thermal blankets?

- Fiberglass fabric is used in the production of thermal blankets due to its excellent insulating properties. The fabric is woven with fine fiberglass strands, which create a heat-resistant barrier. This helps to trap and retain heat, making the thermal blanket highly effective in providing warmth and insulation. The fiberglass fabric also adds durability and strength to the blanket, making it long-lasting and suitable for various applications.

- Q:How is fiberglass fabric cleaned?

- Fiberglass fabric can be cleaned by first removing any loose debris or dirt with a soft brush or vacuum cleaner. Then, mix a mild detergent with warm water and gently scrub the fabric using a sponge or soft cloth. Rinse thoroughly with clean water and allow it to air dry. Avoid using harsh chemicals or abrasive materials that may damage the fiberglass fabric.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

fiberglass cloth with vermiculite coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords