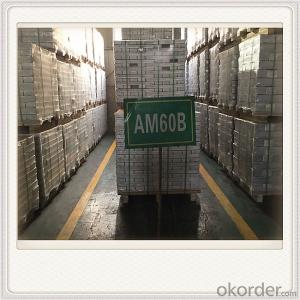

Pure Aluminum Plate

Pure Aluminum Plate Related Searches

Etching Magnesium PlateHot Searches

Pure Aluminum Plate Supplier & Manufacturer from China

Okorder.com is a professional Pure Aluminum Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Pure Aluminum Plate firm in China.Hot Products

FAQ

- Yes, aluminum sheets are commonly used in cryogenic applications due to their excellent low-temperature properties, including low thermal expansion and good resistance to cryogenic liquids.

- Indeed, automotive radiators can be manufactured using aluminum sheets. The lightweight nature of aluminum, along with its exceptional heat transfer qualities and resistance to corrosion, make it a favored material for automotive radiators. The malleability of aluminum sheets allows for effortless shaping and sizing to meet the specific requirements of radiator construction. Furthermore, aluminum radiators outperform traditional copper radiators in terms of cooling efficiency. Consequently, employing aluminum sheets for the production of automotive radiators is a feasible and beneficial choice.

- There are several methods of surface engraving aluminum sheets, including laser engraving, mechanical engraving, chemical etching, and diamond drag engraving. Each method offers different levels of precision and depth, allowing for various artistic or functional purposes.

- How to polish aluminum sheet to be bright?

- you must do some protection work, or you will fail once aluminum contacts air. Aluminum sheet is easy to be oxided and volatilized.

- nan

- AlSO4 CaCl

- Aluminum sheets have the ability to be painted or coated. Aluminum, being a versatile material, can easily be painted or coated in order to enhance its appearance or improve its performance. The key to successfully painting or coating aluminum lies in adequately preparing the surface and using appropriate primers or coatings specifically designed for aluminum. To achieve this, the aluminum sheet's surface must be thoroughly cleaned, devoid of any oils, dirt, or oxidation, and may require sanding or etching to promote adhesion. Once the surface is prepared, a wide array of paints or coatings can be applied, including liquid paints, powder coatings, and anodizing. These finishes offer various advantages such as heightened corrosion resistance, improved durability, enhanced aesthetics, and even specialized properties like heat resistance or anti-microbial properties. It is crucial to seek professional advice or adhere to the manufacturer's instructions to ensure the correct application and long-lasting effects of the paint or coating on aluminum sheets.

- is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.