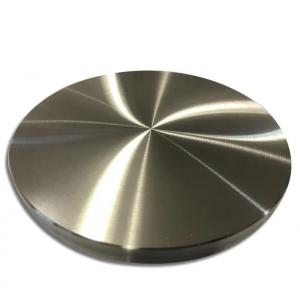

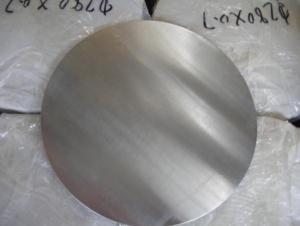

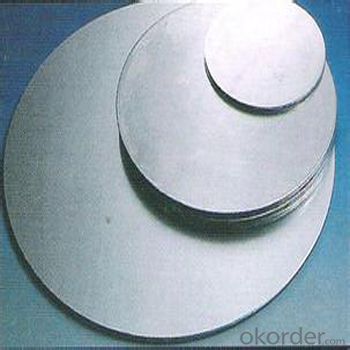

Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALUMINIUM CIRCLE

2.Description

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.

Thin sheets of aluminium are not very effective at attenuating low-frequency magnetic fields. The shielding effectiveness is dependent upon the skin depth. A field traveling through one skin depth will lose about 63 percent of its energy (it is attenuated to 1/e = 1/2.718... of its original energy). Thin shields also have internal reflections that reduce the shielding effectiveness. For effective shielding from a magnetic field, the shield should be several skin depths thick. Aluminium foil is about 1 mil (25 µm); a thickness of 10 mils (250 µm) (ten times thicker) offers less than 1 dB of shielding at 1 kHz, about 8 dB at 10 kHz, and about 25 dB at 100 kHz.

3.Why you want to choose us?

We can supply the best quality and best service!

4.Pictures

5.FAQ

1)Can we supply samples?

Yes, we can!

2)What can you do if you have other quastions?

You can contact us freely at any time!

3)How about our payment term?

LC and TT and other.

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- yes copper wire is better than almunium since coppe is very best conductor that that of almunium

- Q: Can aluminum sheet be used for soundproofing?

- Yes, aluminum sheet can be used for soundproofing to some extent. Aluminum is a dense and rigid material, making it effective at blocking sound transmission. When used in conjunction with other soundproofing materials, such as foam or mineral wool, it can further enhance soundproofing capabilities. However, it is important to note that aluminum sheet alone may not provide complete soundproofing, as it may still allow some sound to pass through due to its thin nature. Additionally, proper installation and sealing of any gaps or openings is crucial for maximizing the soundproofing effectiveness of aluminum sheet.

- Q: Can 101 aluminum sheets be used in architectural cladding?

- Certainly, architectural cladding can indeed utilize 101 aluminum sheets. The lightweight nature, durability, and resistance to corrosion make aluminum a favored option for architectural cladding. Specifically, grade 101 aluminum sheets find widespread use in architectural applications due to their impressive formability and easy workability. These sheets can be effortlessly cut, shaped, and joined to fashion tailor-made cladding solutions. Moreover, aluminum offers the possibility of being coated or anodized, allowing for enhanced aesthetics and added weather protection. Consequently, it is evident that 101 aluminum sheets prove suitable for various architectural cladding projects.

- Q: Are aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is a highly durable and corrosion-resistant material, making it ideal for use in outdoor environments. It can withstand exposure to various weather conditions, including rain, snow, and sunlight, without deteriorating or losing its structural integrity. Additionally, aluminum sheets can be coated or painted to enhance their resistance to fading, scratching, and other forms of wear and tear. This makes them perfect for outdoor applications such as roofing, siding, signage, and decorative elements. Moreover, aluminum is lightweight and easily malleable, allowing for easy installation and customization. Overall, aluminum sheets are a reliable and long-lasting choice for outdoor projects.

- Q: Are aluminum sheets resistant to UV radiation?

- Yes, aluminum sheets are generally resistant to UV radiation. Aluminum is known for its excellent corrosion resistance, and this extends to its resistance to UV radiation as well. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against the harmful effects of UV rays. This oxide layer acts as a shield, preventing the aluminum from deteriorating or fading when exposed to sunlight or other sources of UV radiation. However, it is important to note that prolonged exposure to intense UV radiation may eventually cause some degradation or discoloration of the aluminum surface. Therefore, while aluminum sheets are highly resistant to UV radiation, it is still advisable to provide additional protection, such as coatings or paint, for applications that require extended exposure to harsh UV environments.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: Can aluminum sheets be polished for a mirror-like finish?

- Indeed, a mirror-like finish can be achieved by polishing aluminum sheets. Due to its relatively soft nature, aluminum can be effortlessly polished to a remarkable shine. Typically, the process entails sanding the surface using increasingly finer grades of sandpaper, then buffing with polishing compounds and a gentle cloth or a polishing wheel. The objective is to eliminate any blemishes or marks on the surface, resulting in a sleek and reflective appearance. By employing proper methods and tools, aluminum sheets can be polished to an exquisite shine, rendering them ideal for diverse applications such as decoration, automotive components, or reflective surfaces in optical instruments.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- in my opinion, when people make an argument about how aluminum bats are dangerous i cant help to imagine a cracked wooden bat flying thru the infield. I think that wooden bats are actually more dangerous. a lot of people that don't like aluminum bats say that one day a fly ball is gonna kill someone off of a aluminum bat, but the same thing would probably happen woth a wooden bat. i personally love to use aluminum bats and a hate it when my high school coach makes me use a wooden bat.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

Send your message to us

Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords