Paralink Geogrid

Paralink Geogrid Related Searches

Miragrid Geogrid Terragrid Geogrid Geogrid Layer Alliance Geogrid Unilock Geogrid Earthlock Geogrid Geostar Geogrid Fortrac Geogrid Geogrid Tbl Geogrid Machine Geogrid Alternative Geogrid Gravel Terrafix Geogrid Gravel Geogrid Basalt Geogrid Geogrid Maps Geogrid Paving Geogrid For Gravel Bidirectional Geogrid Geogrid Placement Universal Geogrid Grass Geogrid Geogrid Australia Standartpark Geogrid Geogrid Viewer Geogrid Overlap Geogrid Pavement Stratagrid Geogrid Geogrid Comparison Geogrid ParkingParalink Geogrid Supplier & Manufacturer from China

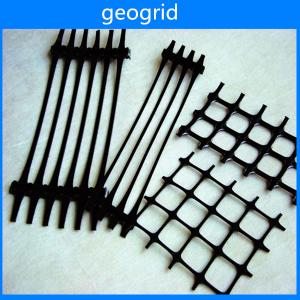

Paralink Geogrid is a high-performance geosynthetic product designed for soil reinforcement and stabilization in various civil engineering applications. This innovative material is engineered to enhance the load-bearing capacity of soil, making it ideal for projects such as road construction, slope stabilization, and retaining walls. Its unique design allows for efficient distribution of stresses, providing greater stability and durability to the overall structure.Paralink Geogrid is widely used in a range of applications where soil reinforcement is necessary. It can be utilized in the construction of roads and highways, where it helps to prevent soil erosion and maintain the structural integrity of the pavement. In addition, it is commonly employed in slope stabilization projects, where it prevents landslides and soil movement, ensuring the safety of nearby structures and infrastructure. Furthermore, Paralink Geogrid is also used in the construction of retaining walls, providing additional support and strength to the wall structure.

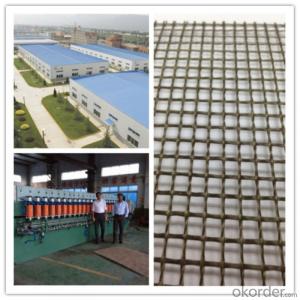

Okorder.com is a reputable wholesale supplier of Paralink Geogrid, offering a vast inventory of this high-quality geosynthetic material. As a leading distributor, they are committed to providing customers with reliable and efficient solutions for their soil reinforcement needs. With a comprehensive selection of Paralink Geogrid products available, Okorder.com ensures that clients can find the perfect solution for their specific project requirements.

Hot Products