Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

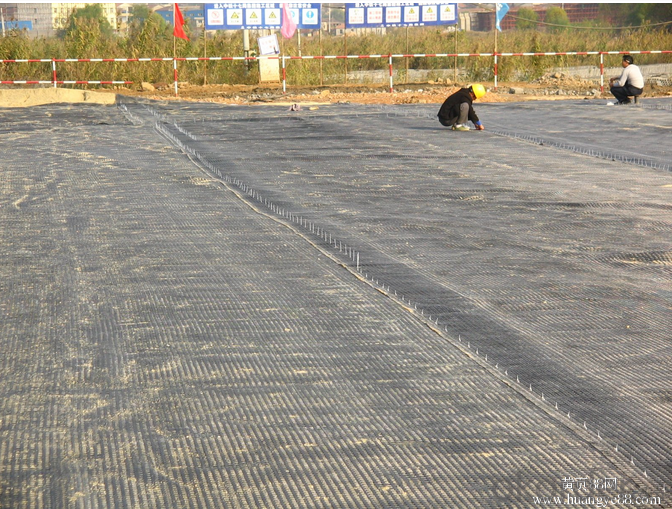

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

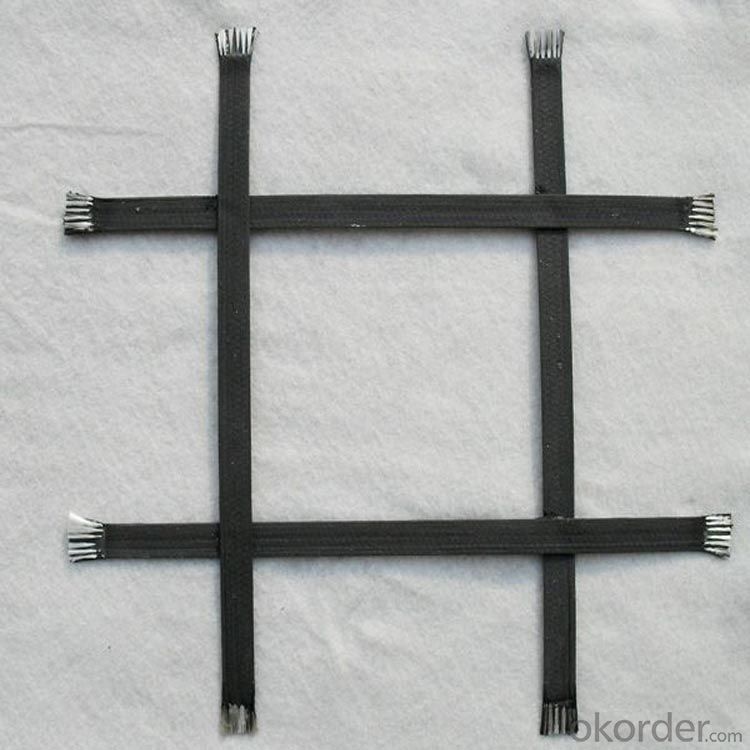

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

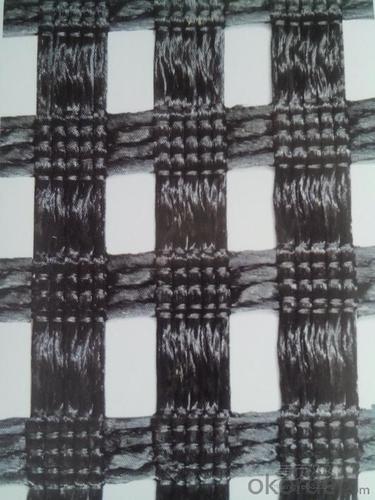

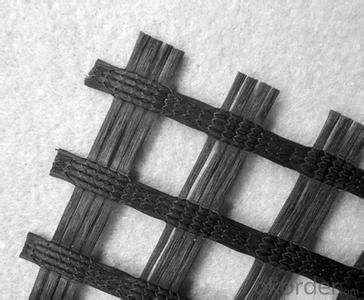

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q: What are the different types of earthwork products available?

- There are several different types of earthwork products available, including but not limited to topsoil, fill dirt, gravel, sand, and mulch. These products serve various purposes such as landscaping, construction, gardening, and erosion control.

- Q: Are earthwork products resistant to pests and insects?

- Yes, earthwork products are generally resistant to pests and insects due to their natural composition and lack of organic materials that attract them.

- Q: What are the benefits of using geotextile tubes in environmental dredging?

- Geotextile tubes offer several benefits in environmental dredging. Firstly, they provide effective containment and dewatering solutions, allowing for the separation of water and solids during the dredging process. This helps in reducing the volume of material to be disposed of and minimizing the environmental impact. Secondly, geotextile tubes are cost-effective compared to traditional dewatering methods. They require less labor and equipment, resulting in lower project costs. Furthermore, the use of geotextile tubes facilitates the reuse of clean water, as it can be separated and discharged back into the environment. This is beneficial in conserving water resources and minimizing the need for additional water supply. Lastly, geotextile tubes are versatile and can be used in various dredging projects, including shoreline restoration, environmental remediation, and sediment removal. Their flexibility and adaptability make them a valuable tool in achieving sustainable and eco-friendly dredging practices.

- Q: How are precast concrete products used in earthwork?

- Precast concrete products are commonly used in earthwork projects for various purposes. They can be used as retaining walls, culverts, manholes, and stormwater management structures. These precast elements provide structural integrity and durability, making them ideal for withstanding the forces and pressures exerted by the surrounding earth. Additionally, their modular design allows for easy installation and customization, reducing construction time and costs. Overall, precast concrete products play a crucial role in earthwork by providing reliable and efficient solutions for various construction needs.

- Q: Are earthwork products resistant to graffiti?

- No, earthwork products are not inherently resistant to graffiti.

- Q: What are the benefits of using geosynthetic reinforcement for soil stabilization?

- Geosynthetic reinforcement offers several benefits for soil stabilization. Firstly, it enhances the strength and load-bearing capacity of the soil, allowing it to withstand heavy loads and prevent settlement. Secondly, it improves the overall stability of the soil, reducing the risk of erosion and slope failure. Additionally, geosynthetic reinforcement can be easily installed, saving time and labor costs compared to traditional stabilization methods. It is also a cost-effective solution as it requires less excavation and can be reused in other projects. Finally, geosynthetics offer long-term durability and resistance to environmental factors, ensuring a sustainable and reliable soil stabilization solution.

- Q: Characteristics of Modern Civil Engineering Materials

- To understand the characteristics of modern civil engineering materials: 1, high-performance materials, such as the development of lightweight, high strength, high durability, excellent decorative and versatile materials, and make full use of and play a variety of materials, the use of composite technology to create Composite material with special function. 2, make full use of local materials, to minimize the natural resources, extensive use of tailings, waste, garbage and other waste as the production of civil engineering materials resources, as well as the protection of natural resources and maintain the balance of the ecological environment. 3, energy conservation, the use of low energy consumption, no pollution of the production technology, give priority to the development and production of low energy consumption materials and can reduce the energy consumption of buildings using energy-saving materials. 4, the material production should not use harmful to the health of additives and pigments, such as formaldehyde, lead, cadmium, chromium and its compounds, while the development of beneficial materials to the human body, such as antibacterial, sterilization, deodorization, Fire, temperature, degaussing, radiation, anti-static and so on. 5, the product can be recycled in the regeneration of He used, non-polluting waste to prevent secondary pollution.

- Q: What are the benefits of using geotextiles in green roof applications?

- There are several benefits of using geotextiles in green roof applications. Firstly, geotextiles act as a protective layer, preventing roots from penetrating the waterproofing membrane and causing damage. Secondly, they provide drainage, allowing excess water to flow out of the green roof system and preventing waterlogging. This helps in maintaining the health of plants and prevents the roof from becoming too heavy. Additionally, geotextiles help in retaining moisture and nutrients, reducing the need for frequent irrigation and fertilization. Lastly, they enhance the overall stability and longevity of the green roof system by preventing soil erosion and promoting proper root growth.

- Q: What are the benefits of using geotextile fabrics in earthwork projects?

- Geotextile fabrics offer numerous benefits in earthwork projects. Firstly, they act as a barrier to prevent soil erosion by stabilizing the soil and preventing it from being washed away by water. Additionally, they enhance soil drainage and filtration, allowing water to pass through while retaining the soil particles. This helps in preventing waterlogging and maintaining the integrity of the soil. Geotextile fabrics also provide reinforcement to the soil, increasing its load-bearing capacity and improving the overall stability of the project. Moreover, these fabrics are durable, resistant to chemicals and UV rays, and have a longer lifespan, making them a cost-effective solution. Overall, the use of geotextile fabrics in earthwork projects reduces maintenance costs, extends the lifespan of the project, and promotes sustainability.

- Q: How do earthwork products help with soil remediation?

- Earthwork products, such as geotextiles and geomembranes, play a crucial role in soil remediation. Geotextiles act as a barrier, preventing contaminants from migrating across different soil layers. They also help in soil stabilization by providing reinforcement and reducing erosion. Geomembranes, on the other hand, are impermeable liners that prevent the leaching of contaminants into groundwater or surrounding areas. By using these earthwork products, soil remediation becomes more effective, as they aid in containing and isolating pollutants, ultimately leading to the restoration and improvement of the soil quality.

Send your message to us

Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords