Geogrid Menards

Geogrid Menards Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Menards Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Menards supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Menards firm in China.Hot Products

FAQ

- Physical characteristics of geogrid construction method

- 2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.5, one-way geogrid for processing landfills: Geogrid and other synthetic materials using a combination of Soil Treatment Landfill, can effectively solve the problem of gas emissions derived from the uneven settlement of foundation, and can improve the landfill to maximize storage capacity.6, one-way geogrid special purpose: low temperature resistance. Low temperature resistance of geogrid Lianyi, at - 45 C and 50 C - repeated 200 cycles, the performance indexes meet the requirements, and has been applied to the test of the Qinghai Tibet railway, the North less ice permafrost and ice rich permafrost and ice rich permafrost bad geology.

- As well as how to fill out the form, thank you!! Urgently

- Do you need a test report for a two-way geogrid

- Yes, geogrids are generally resistant to chemical leaching. Geogrids are typically made from high-density polyethylene (HDPE) or other chemically inert materials, which makes them highly resistant to chemical leaching. This resistance helps maintain the structural integrity and long-term performance of geogrids in various applications, including soil stabilization, erosion control, and reinforcement projects.

- What is the market price of the geotechnical grid in 2017?

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.

- Geogrids prevent soil erosion by providing stability and reinforcement to the soil. They are typically made of high-strength materials, such as polyester or polypropylene, and are installed within the soil to distribute and transfer loads. This helps to increase the soil's resistance to erosion caused by factors like water flow or slope instability. The geogrids act as a barrier that holds the soil particles together, preventing them from being washed away or displaced.

- In the reinforced earth retaining wall, the geogrid is connected with the panel

- Is it a one-way geogrid? Special connecting rod

- Yes, geogrids are suitable for use in ground reinforcement for wind farms. Geogrids provide excellent load-bearing capacity, soil stabilization, and erosion control, making them ideal for reinforcing the ground in areas with high wind speeds. They distribute loads effectively, reduce soil movement, and enhance the overall stability of the ground, ensuring the proper functioning and longevity of wind farm infrastructure.

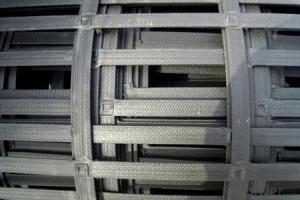

- Details of fiberglass geogrid

- 3, high temperature rutThe asphalt concrete has rheological properties at high temperature, specific performance in summer: asphalt road surface soft and sticky; under the vehicle load, the stress area from depression, vehicle load after the removal of the asphalt surface layer cannot be completely restored to the loading condition before, which produce plastic deformation in the vehicle repeatedly; under the action of rolling plastic deformation accumulation, rutting. We analyze the asphalt pavement structure, because of high temperature asphalt concrete with rheology, while under load, without any constraint mechanism can aggregate movement of the asphalt concrete surface layer, resulting in asphalt surface layer goes on, this is the main reason of the formation of rutting.The fiberglass geogrid is used in the asphalt overlay, which plays the role of skeleton in the asphalt surface layer. The asphalt concrete aggregate throughout the grid, to form a composite mechanical interlocking system, limit the aggregate movement, increase the lateral cover surface layer in asphalt binding, each part of the asphalt layer in each other, to prevent the asphalt surface layer goes on, which plays the role of rutting resistance.