Z60 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

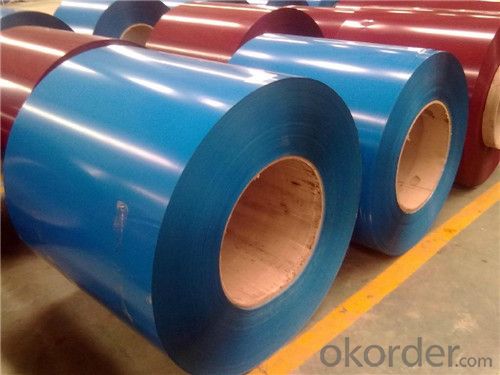

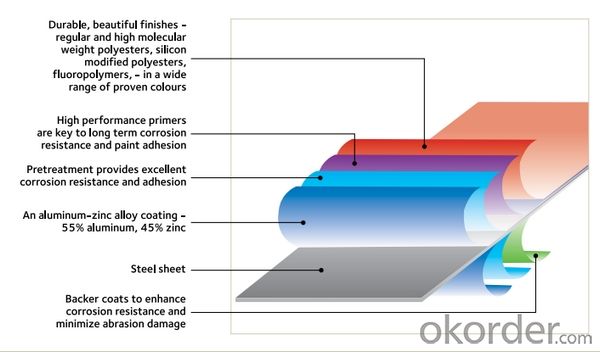

Structure of Z60 Rolled Prepainted Steel Coil for Construction

Description of Z60 Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Z60 Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Z60 Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of Z60 Rolled Prepainted Steel Coil for Construction

Product | Z60 Rolled Prepainted Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z60 Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the substrate for steel tiles?

Hot dipped galvanized or gavalume, pre-painted galvanized.

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: What is galvanized steel coil?

- Galvanized steel coil is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves immersing the steel coil in a bath of molten zinc, which forms a protective layer on the surface of the steel. This layer not only prevents corrosion but also provides a barrier against scratches and other damage. Galvanized steel coil is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability and resistance to rust. It is often used for making roofing materials, pipes, and automotive parts, among other applications. Overall, galvanized steel coil is a versatile and cost-effective solution for ensuring the longevity and integrity of steel products.

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers as they provide strength and stability to the trailer's structure. These coils are typically shaped and welded to form the trailer's frame, ensuring durability and load-bearing capacity. Additionally, steel coils can be used to reinforce certain components of the trailer, such as the axles or suspension system, to enhance its overall performance and withstand the demands of agricultural work.

- Q: How are steel coils inspected for defects after recoiling?

- Steel coils are inspected for defects after recoiling through a thorough visual examination, which involves inspecting the surface for any visible defects such as scratches, dents, or cracks. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle inspection may be used to identify any internal defects that are not visible to the naked eye.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its purpose and industry standards. However, common dimensions for steel coils include a width ranging from 600mm to 2000mm, a coil diameter of around 1000mm to 2000mm, and a weight capacity ranging from a few tons to several dozen tons.

- Q: What are the factors affecting the formability of steel coils?

- The factors affecting the formability of steel coils include the composition and microstructure of the steel, the thickness and width of the coil, the temperature and speed of the forming process, the lubrication used during forming, and the presence of any surface defects or contaminants.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: How do steel coils contribute to sustainability in manufacturing?

- Steel coils contribute to sustainability in manufacturing in several ways. Firstly, steel is a highly recyclable material, meaning that steel coils can be easily recycled and reused, reducing the need for new steel production and conserving natural resources. Additionally, steel is known for its durability and strength, resulting in longer-lasting products and reduced waste. Steel coils also play a vital role in energy-efficient manufacturing processes, as they can be easily formed into various shapes and sizes, optimizing material usage and minimizing energy consumption. Furthermore, steel's versatility makes it suitable for a wide range of applications, allowing manufacturers to create more sustainable products across industries. Overall, steel coils contribute to sustainability by promoting resource conservation, waste reduction, energy efficiency, and the production of durable and eco-friendly products.

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders vary depending on factors such as the supplier, quantity, and specifications required. However, lead times can range from a few weeks to several months, with an average of 6-8 weeks being common.

Send your message to us

Z60 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords