Z41 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z41 BMP Rolled Steel Coil Construction Roofing Construction

Description of Z41 BMP Rolled Steel Coil Construction Roofing Construction

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Z41 BMP Rolled Steel Coil Construction Roofing Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Z41 BMP Rolled Steel Coil Construction Roofing Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.  Specifications of Z41 BMP Rolled Steel Coil Construction Roofing Construction

Specifications of Z41 BMP Rolled Steel Coil Construction Roofing Construction

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Z41 BMP Rolled Steel Coil Construction Roofing Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

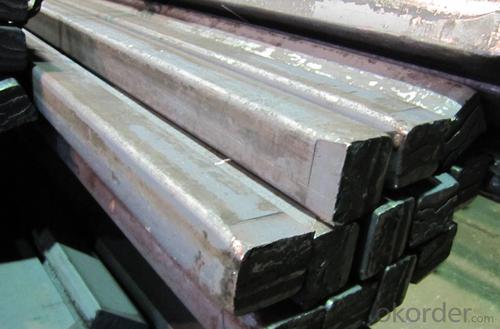

- Q: How are steel billets used in the manufacturing of shipbuilding components?

- Steel billets are used in the manufacturing of shipbuilding components as they serve as the raw material for forging, rolling, and shaping various structural parts of a ship, such as hull sections, bulkheads, and frames. These billets are heated and formed into desired shapes through processes like hot rolling, forging, or extrusion, ensuring the required strength, durability, and dimensional accuracy of the shipbuilding components.

- Q: How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are an essential raw material in the manufacturing of rail and transportation systems. These billets serve as the starting point for the production of various components, such as rails, wheels, axles, and structural supports. Through a series of processes like rolling, forging, and machining, steel billets are transformed into these vital parts, which provide strength, durability, and stability to rail tracks, locomotives, and other transportation vehicles. In summary, steel billets are crucial in ensuring the reliability and safety of rail and transportation systems.

- Q: Can steel billets be painted or coated for decorative purposes?

- Yes, steel billets can be painted or coated for decorative purposes. Painting or coating steel billets not only enhances their appearance but also provides protection against corrosion and other environmental factors. Various types of paints and coatings can be used, such as epoxy, powder coating, or metallic finishes, to achieve the desired decorative effect. These coatings can be applied to steel billets through processes like spray painting, electrostatic coating, or hot-dipping. It is important to properly prepare the surface of the steel billets before applying the paint or coating to ensure good adhesion and longevity of the decorative finish.

- Q: How are steel billets cleaned before further processing?

- Steel billets are cleaned before further processing through a series of steps to remove any impurities or contaminants. The cleaning process starts with the billets being subjected to a high-pressure water jet to remove any loose scale or dirt on the surface. This water jetting helps in removing most of the loose particles and provides a clean surface for further cleaning. After the initial water jetting, the billets are then immersed in an acid bath. The acid bath can be a mixture of different chemicals like hydrochloric acid, sulfuric acid, or a combination of both. The acid bath helps in removing any remaining scale or oxide layers on the surface of the billets. The acid reacts with these impurities, dissolving them and leaving a clean surface behind. Once the acid cleaning is complete, the billets are rinsed thoroughly with water to remove any traces of the acid. This rinsing process is crucial to ensure that no acid residue remains on the surface, as it could potentially affect the quality of the final product. After rinsing, the billets are then dried using hot air or in a furnace to remove any moisture. This drying process is necessary to prevent any rusting or corrosion from occurring on the surface of the billets. Overall, the cleaning of steel billets before further processing is a crucial step in ensuring the quality and integrity of the final product. It helps in removing impurities, scale, and oxide layers from the surface, providing a clean and uniform surface for subsequent processing operations.

- Q: What are the different types of steel billet forming processes?

- The different types of steel billet forming processes include hot rolling, cold rolling, extrusion, forging, and casting.

- Q: What are the different surface treatments applied to stainless steel billets?

- There are several different surface treatments that can be applied to stainless steel billets, depending on the desired outcome and application. Some common treatments include passivation, pickling, electropolishing, and blasting. Passivation helps to improve corrosion resistance by removing any free iron from the surface. Pickling involves the use of acids to remove impurities and oxide layers from the surface. Electropolishing is an electrochemical process that provides a smooth and shiny finish. Blasting, on the other hand, involves using abrasive particles to remove surface contaminants and create a textured finish. These treatments can enhance the appearance, cleanliness, and durability of stainless steel billets for various industrial applications.

- Q: How are steel billets used in the manufacturing of agricultural machinery?

- Steel billets are an essential component in the manufacturing of agricultural machinery. These billets, which are semi-finished steel products, serve as the raw material for various parts and components used in agricultural machinery. One of the primary uses of steel billets in the manufacturing process is for forging and casting. Forging involves heating the billets to a high temperature and then shaping them using mechanical pressure, while casting involves pouring molten metal into a mold. Both processes allow for the creation of complex and durable components that are necessary for agricultural machinery. Steel billets are used to manufacture a wide range of agricultural machinery parts, such as engine components, transmission gears, axles, and hydraulic cylinders. These parts require excellent strength, durability, and resistance to wear, which steel billets provide. Additionally, steel's high tensile strength ensures that the machinery can withstand the demanding conditions of agricultural operations. Moreover, steel billets are used for manufacturing the frames and chassis of agricultural machinery. The frames need to be robust to support the weight and withstand the stress and vibrations generated during operation. Steel billets allow for the creation of sturdy and rigid frames that ensure the longevity and structural integrity of the machinery. Furthermore, steel billets are utilized in the production of cutting and harvesting tools, such as blades, discs, and plowshares. The exceptional hardness and sharpness of steel make it an ideal material for these tools, enabling efficient and precise agricultural operations. In summary, steel billets play a crucial role in the manufacturing of agricultural machinery. Their versatility, strength, and durability make them a suitable material for various components and parts, ensuring that the machinery can withstand the demanding conditions of agricultural operations and perform efficiently.

- Q: Can steel billets be used in the production of electrical appliances?

- Steel billets have the potential to be utilized in the manufacturing of electrical appliances. These semi-finished products, commonly employed in the production of diverse steel goods, can be further manipulated and molded into the necessary components for electrical appliances. These components may include casings, frames, brackets, and other structural parts. The utilization of steel offers robustness, longevity, and protection against corrosion, rendering it appropriate for the rigorous demands of electrical appliances. Moreover, steel is readily accessible and cost-efficient, making it a favored option for the production of electrical appliances.

- Q: What are the different types of steel billet rolling mills?

- There are several types of steel billet rolling mills, including blooming mills, slabbing mills, and continuous casting mills.

- Q: How do steel billets contribute to the automotive industry?

- The automotive industry heavily relies on steel billets as the primary raw material for manufacturing different automotive components. These components, including engine parts, transmission systems, chassis, suspension systems, and other critical parts, are crucial for ensuring the safety, performance, and durability of vehicles. A significant contribution of steel billets to the automotive industry lies in their exceptional strength and durability. Steel is widely known for its high tensile strength, which enables it to withstand extreme forces and provide structural integrity to automotive components. This strength is particularly crucial in areas such as the frame, where it ensures passenger safety in the event of a collision. Moreover, steel billets offer excellent formability and versatility, allowing manufacturers to create intricate and complex automotive parts with precision. This enables the production of components that meet the specific design requirements of different vehicle models, ensuring optimal performance and functionality. Another advantage of steel billets is their cost-effectiveness. Compared to alternatives like aluminum or carbon fiber, steel is a relatively affordable material. Its widespread availability and production efficiency make it an economical choice for mass production, helping to keep vehicle prices reasonable for consumers. Furthermore, steel billets possess excellent heat resistance and thermal conductivity properties, making them ideal for use in engine components, such as pistons and cylinder heads. They can withstand high temperatures and efficiently transfer heat. Additionally, steel billets contribute to the sustainability of the automotive industry. Steel is highly recyclable, with a recycling rate of around 90%. This allows for the eco-friendly disposal and reuse of steel components, reducing the environmental impact of the automotive manufacturing process. In conclusion, steel billets play a crucial role in the automotive industry by providing the necessary strength, durability, formability, and cost-effectiveness for manufacturing various automotive components. Their versatility and recyclability further contribute to the sustainability of the industry. Without steel billets, the automotive industry would face challenges in producing safe, reliable, and affordable vehicles.

Send your message to us

Z41 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords