Z28 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

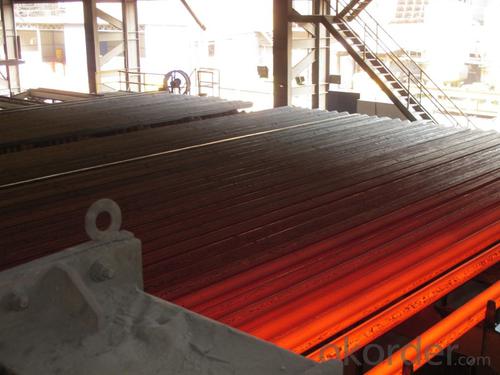

Structure of Z28 BMP Rolled Steel Coil Construction Roofing Construction

Description of Z28 BMP Rolled Steel Coil Construction Roofing Construction

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Z28 BMP Rolled Steel Coil Construction Roofing Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Z28 BMP Rolled Steel Coil Construction Roofing Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Z28 BMP Rolled Steel Coil Construction Roofing Construction

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Z28 BMP Rolled Steel Coil Construction Roofing Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: How are steel billets used in the manufacturing of power generation equipment?

- The manufacturing of power generation equipment relies heavily on steel billets, which are indispensable raw materials. These billets, cast from molten steel, take the form of large rectangular or square-shaped semi-finished steel products. They are then either hot rolled or forged to achieve their final shape. Within the power generation equipment context, steel billets are primarily employed in the construction of turbine components, such as turbine blades and rotors. Additionally, they are used in the fabrication of generator casings and other structural parts. The exceptional strength and durability of steel make it the ideal material for these critical components, which must endure high temperatures, pressure, and rotational forces. The process commences with the careful selection of a suitable grade of steel billet, based on the specific requirements of the power generation equipment. Subsequently, the billets are heated to an appropriate temperature and then forged or hot rolled to shape them as desired. This process necessitates precise techniques, such as machining, cutting, and shaping, to achieve the required dimensions and surface finish. Once the turbine components and other parts are formed from the steel billets, they undergo further treatments, including heat treatment, surface coating, and machining. These treatments aim to enhance their mechanical properties and ensure compatibility with the power generation system. Ultimately, the final products are assembled into power generation equipment, which may consist of gas turbines, steam turbines, wind turbine components, or generator sets. Steel billets play a critical role in the manufacturing of power generation equipment as they provide the necessary strength, durability, and performance required for efficient and reliable operation. The quality and precision involved in the production of steel billets directly impact the overall performance and lifespan of the power generation equipment, making them an essential component in the industry.

- Q: How are steel billets used in the production of oil and gas machinery?

- The production of oil and gas machinery heavily relies on steel billets. These billets are essentially semi-finished pieces of steel that undergo further processing to produce various components needed in the oil and gas industry. To begin with, steel billets are essential in manufacturing the key structural components of oil and gas machinery, such as frames, bases, and casings. These components provide the necessary strength, stability, and support to the equipment, ensuring their safe and efficient operation even in harsh operating conditions. Furthermore, steel billets are also utilized in the production of critical rotating parts, including shafts, gears, and turbines. These components experience high loads, intense pressure, and extreme temperatures, making exceptional strength and durability a requirement. Steel billets, known for their superior mechanical properties, are an ideal material for manufacturing such parts. In addition, steel billets are employed in the production of valves, fittings, and connectors that are integral to oil and gas machinery. These components are responsible for controlling the flow of oil or gas, regulating pressure, and ensuring secure connections between various equipment and pipelines. Steel billets are chosen for these applications due to their excellent corrosion resistance, which is crucial in environments where oil and gas are present. Moreover, steel billets find application in the fabrication of heat exchangers and pressure vessels used in the oil and gas industry. Heat exchangers play a vital role in cooling or heating fluids, while pressure vessels store and transport hazardous substances safely. Steel billets are preferred for these applications due to their high thermal conductivity, excellent weldability, and resistance to extreme pressures. In summary, steel billets are extensively utilized in the production of oil and gas machinery because of their exceptional mechanical properties, corrosion resistance, and thermal conductivity. These billets provide the necessary strength, durability, and reliability to the components and equipment required in the oil and gas industry, ensuring safe and efficient operations in this critical sector.

- Q: How are steel billets used in the manufacturing of structural steel?

- Steel billets are a crucial raw material in the manufacturing of structural steel. They are heated, shaped, and then cooled to form various steel products such as beams, columns, and plates. These billets serve as the starting point for the production process, where they are further processed and transformed into different shapes and sizes to meet the specific requirements of construction projects.

- Q: How are steel billets used in the manufacturing of pressure vessels?

- Steel billets are an essential component in the manufacturing of pressure vessels. These billets, which are semi-finished metal products, are typically made through a process called casting or extrusion. They are shaped into a solid square or rectangular form, ensuring a consistent and uniform material for further processing. To start the manufacturing process, the steel billets are heated to a specific temperature to make them more malleable and easier to work with. Once heated, they are placed into a forging machine, where they are subjected to intense pressure and shaping. This forging process helps to eliminate any defects or inconsistencies in the billet's structure, resulting in a stronger and more durable material. After forging, the steel billets are further processed through various techniques, such as rolling or machining, to achieve the desired dimensions and shape required for pressure vessel fabrication. These techniques help to refine the billet's surface finish and improve its mechanical properties. Once the billets have been shaped and processed, they are cut into smaller sections, which serve as the building blocks for pressure vessel construction. These sections are then welded together to form the shell of the vessel, ensuring a tight and secure seal to contain the high-pressure fluids or gases. The use of steel billets in pressure vessel manufacturing is crucial because of their superior strength, durability, and resistance to high-pressure environments. The uniformity and consistency of the billets provide a reliable material for fabricating vessels that can withstand extreme conditions and ensure the safety and integrity of the contents within. In summary, steel billets play a vital role in the manufacturing of pressure vessels as they provide the foundation for constructing the vessel's shell. Through a series of heating, forging, and processing techniques, the billets are transformed into strong and durable sections that are then welded together to form the final vessel. The use of steel billets ensures the structural integrity and reliability of pressure vessels, making them suitable for a wide range of industrial applications.

- Q: What are the main types of defects found in steel billets?

- The main types of defects found in steel billets include surface defects such as cracks, pits, and scars, internal defects like inclusions, blowholes, and voids, as well as dimensional defects such as improper shape, size, or straightness.

- Q: Can steel billets be painted or coated for decorative purposes?

- Yes, steel billets can be painted or coated for decorative purposes. Painting or coating steel billets not only enhances their appearance but also provides protection against corrosion and other environmental factors. Various types of paints and coatings can be used, such as epoxy, powder coating, or metallic finishes, to achieve the desired decorative effect. These coatings can be applied to steel billets through processes like spray painting, electrostatic coating, or hot-dipping. It is important to properly prepare the surface of the steel billets before applying the paint or coating to ensure good adhesion and longevity of the decorative finish.

- Q: What is the difference between hot-rolled and cold-rolled steel billets?

- The main difference between hot-rolled and cold-rolled steel billets lies in the manufacturing process. Hot-rolled steel billets are formed by heating the steel to a high temperature and then rolling it while it is still hot, resulting in a rougher and less precise surface finish. On the other hand, cold-rolled steel billets are formed by cooling the steel and then rolling it at room temperature, which produces a smoother and more precise surface finish. This difference in manufacturing process also affects the mechanical properties of the steel, with hot-rolled steel generally having higher tensile strength but lower dimensional accuracy compared to cold-rolled steel.

- Q: How are steel billets used in the production of oil and gas equipment?

- Steel billets are used in the production of oil and gas equipment as they serve as the raw material for manufacturing various components such as pipes, valves, fittings, and other structural parts. These billets undergo further processing, such as hot rolling or forging, to form the desired shape and strength required for the specific equipment. The use of steel billets ensures the durability, strength, and corrosion resistance needed to withstand the demanding conditions of the oil and gas industry.

- Q: What are the different types of steel billet quality control tests?

- To ensure the integrity and suitability of steel billets for further processing, various types of quality control tests are conducted. These tests play a vital role in maintaining the desired quality standards in the steel industry and detecting any defects or inconsistencies in the billets. Some commonly used tests for steel billet quality control are as follows: 1. Visual Inspection: This test involves visually examining the billets to identify surface defects like cracks, seams, or dents. It is a fundamental form of quality control and can be carried out quickly. 2. Dimensional Inspection: In this test, the dimensions of the billets are measured and compared to specified tolerances. This ensures that the billets fall within the required size range and meet the dimensional requirements for further processing. 3. Chemical Composition Analysis: This test involves analyzing the chemical composition of the steel billets to ensure they meet the specified requirements. It includes determining the percentages of different elements such as carbon, manganese, sulfur, and phosphorus. 4. Mechanical Testing: This test evaluates the mechanical properties of the steel billets, such as tensile strength, yield strength, and elongation. These properties are crucial in determining the billets' suitability for specific applications. 5. Ultrasonic Testing: This non-destructive testing method utilizes ultrasonic waves to detect internal defects like cracks or voids in the billets. It is particularly effective in identifying hidden defects that may not be visible during visual inspection. 6. Magnetic Particle Inspection: This test involves applying a magnetic field to the billets and then introducing magnetic particles to the surface. Any surface or near-surface defects will cause the particles to gather, indicating the presence of a defect. 7. Eddy Current Testing: This method uses electromagnetic induction to detect surface defects or variations in the billets' electrical conductivity. It is useful in identifying cracks, voids, or inconsistencies in the billets' microstructure. 8. Microstructure Analysis: This test involves examining the microstructure of the steel billets under a microscope to assess homogeneity, grain size, and the presence of any undesirable phases. It aids in determining the overall quality and suitability of the billets for further processing. These tests, alongside other specific tests, are an integral part of steel billet quality control. By conducting these tests, manufacturers can ensure that the billets meet the required standards and possess the necessary properties for their intended applications.

- Q: What industries use steel billets?

- Due to their strength, durability, and versatility, steel billets are extensively used in a wide range of industries. The construction industry heavily relies on steel billets for the production of structural components like beams, columns, and girders, which provide vital support and strength in infrastructure projects such as buildings and bridges. In the automotive industry, steel billets are crucial for manufacturing various car parts, including engine components, chassis, and suspension systems. The preference for steel billets in this industry stems from their high strength-to-weight ratio, which enhances fuel efficiency and overall performance. Manufacturing industries like machinery, equipment, and tool production also heavily depend on steel billets. These billets are used to manufacture critical components such as gears, shafts, valves, which require exceptional strength, durability, and precision. Additionally, steel billets play a vital role in the energy sector, particularly in the production of oil and gas pipelines. These pipelines require specific grades of steel billets that can withstand harsh conditions, high pressures, and corrosive environments. Moreover, steel billets have applications in other sectors such as shipbuilding, aerospace, mining, and agriculture. They are widely utilized in any industry where strength, durability, and reliability are paramount. In conclusion, the remarkable mechanical properties of steel billets enable their diverse applications across multiple industries. The demand for steel billets remains strong as they are an indispensable raw material for producing critical components in numerous sectors.

Send your message to us

Z28 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords