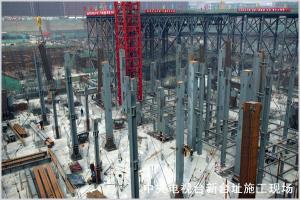

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TMCPhigh-strengthsteel(non-tempered):E500.Q500E.S500M.

1.SA516Gr70. SA516Gr65.S355series.P355series.Q345Rseries.AH32-36.DH32-36.EH32-36.Intensitylevel isQ345Eclass.P460.S460 (-20 ℃impact)seriesQ460Dclasses.

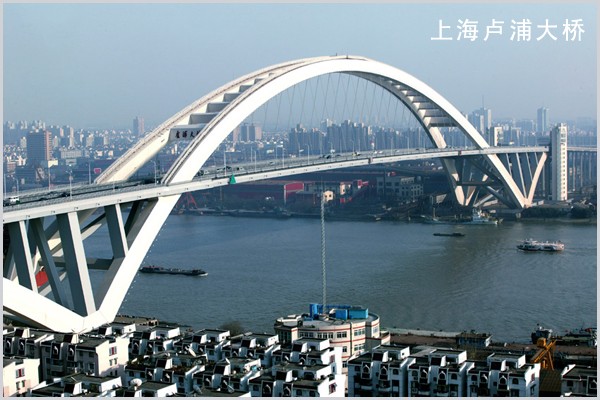

2containers.Ship plate steeland other specialsteels,at the sameintensity levelbase priceplus500 yuan/ ton.

1: AsolutionHICSteel(HIC-A)toBsolutionHICsteel(HIC)basisplus300 yuan/ton.

2: R-HICHICsteeltosteelAsolution(HIC)basisplus500 yuan/ ton.

3: TypeII HICsteel100 yuan/ton, IIItypeHICsteelplus400 yuan/ ton.

4:For theHICsteelQ345R SA516Gr70 SA516Gr65correspondingclassQ345RQ245RQ245R SA516Gr60correspondingclass..

6, nuclearHRsteelcontainersincludeda quality plan,the completion ofthe report,all the requirements forsimulationafter weldingand so on.

- Q: What is the modulus of elasticity of steel sheets?

- The modulus of elasticity of steel sheets typically ranges between 190 to 210 gigapascals (GPa).

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made of iron and carbon, with trace amounts of other elements. It is susceptible to rust and corrosion, requiring regular maintenance and protection. On the other hand, stainless steel sheet is an alloy of iron, carbon, and chromium, with additional elements like nickel and molybdenum. It has a higher resistance to rust and corrosion, making it suitable for applications in harsh environments. Stainless steel sheet also offers better strength and durability compared to plain carbon steel sheet.

- Q: How do steel sheets perform in terms of vibration damping?

- Steel sheets have good vibration damping properties due to their high density and stiffness. They are effective in reducing vibrations and minimizing noise transmission, making them suitable for various applications requiring vibration control and noise reduction.

- Q: Can steel sheets be used in electrical applications?

- Yes, steel sheets can be used in electrical applications. They are commonly used as magnetic cores in transformers and other electrical machines. Additionally, steel sheets are often used as a protective casing or enclosure for electrical equipment.

- Q: What are the different methods of joining steel sheets together?

- There exists a variety of techniques for connecting steel sheets, each possessing unique benefits and applications. Some commonly employed techniques include: 1. Welding: Utilized extensively, welding effectively joins steel sheets by melting their edges and fusing them together through the application of heat. Different welding processes, including arc welding, gas welding, and spot welding, are available, each tailored to specific applications. 2. Riveting: Riveting, a mechanical method, utilizes metal fasteners called rivets to connect steel sheets. Rivets are inserted into pre-drilled holes in the sheets and secured in place by hammering or pressing. Riveting is renowned for producing robust and long-lasting joints. 3. Bolting: Bolting employs bolts and nuts to hold steel sheets together. Holes are drilled through the sheets, and bolts are inserted from one side, with nuts tightened on the other side to secure the joint. Bolting offers the advantages of being quick, easy to assemble, and allows for disassembly if necessary. 4. Adhesive bonding: Adhesive bonding employs specialized adhesives to join steel sheets. The adhesive is applied between the surfaces to be joined and forms a strong bond as it cures. This method is commonly employed in industries where welding may distort the materials or is not feasible due to the specific materials involved. 5. Mechanical fastening: Mechanical fasteners such as screws, self-tapping screws, or nails may be used to join steel sheets. These fasteners create a sturdy connection by penetrating the sheets and holding them in place. Mechanical fastening is relatively swift and does not necessitate any specialized equipment. 6. Clinching: Clinching is a cold forming process that connects steel sheets by deforming the material without the use of external heat. It involves pressing the sheets together and forming a mechanical interlock. Clinching is frequently employed in the automotive industry due to its high-speed production capabilities and joint strength. Each technique possesses its own advantages based on factors such as joint strength, ease of assembly, cost, and specific application requirements. The selection of a joining technique depends on the intended purpose of the joint, material properties, and the environmental conditions to which the joint will be exposed.

- Q: What are the different manufacturing processes for steel sheets?

- Steel sheets can be manufactured through various processes, each with its own unique characteristics and applications. Some commonly used methods include: 1. The most widely employed technique is hot rolling, which involves heating the steel billet or slab to a high temperature and passing it through rollers to reduce its thickness. As a result, the sheets have a smooth surface and excellent mechanical properties. 2. Cold rolling, on the other hand, rolls the steel at room temperature, yielding sheets with higher dimensional accuracy and surface finish. This process is often employed to produce sheets with tight tolerances and improved surface quality. 3. Galvanizing is a process where steel sheets are coated with a layer of zinc to prevent corrosion. The sheets are either immersed in molten zinc or electroplated with it, forming a protective barrier that extends the steel's lifespan. 4. Coating processes can also be applied to steel sheets to enhance their properties or appearance. For instance, powder coating involves electrostatically applying a dry powder that is then cured under heat. Paint coating, on the other hand, entails applying a liquid paint to the surface and allowing it to dry. 5. Pickling, a chemical process, is employed to remove impurities like rust, scale, and oxides from the surface of steel sheets. Typically, the sheets are immersed in an acid bath that dissolves these unwanted materials, leaving behind a clean surface. 6. Once the steel sheets are manufactured, they can undergo cutting and forming operations. Laser cutting, plasma cutting, or shearing can be utilized to shape the sheets into desired sizes and shapes. Additionally, the sheets can be formed into various products using techniques like bending, deep drawing, or roll forming. These examples highlight the different manufacturing processes for steel sheets, and the choice of method depends on factors such as desired sheet properties, surface finish, and intended application.

- Q: Can the steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding. Steel is a ferromagnetic material, which means it can effectively redirect and absorb magnetic fields. When steel sheets are used to shield against magnetic fields, they create a barrier that helps to prevent the penetration of magnetic flux into a designated area. This property makes steel sheets an excellent choice for applications where magnetic shielding is required, such as in electronics, medical devices, and sensitive laboratory equipment. However, the effectiveness of steel sheets for magnetic shielding can depend on various factors, including the thickness and composition of the steel, as well as the strength and frequency of the magnetic field being shielded. Therefore, it is important to consider these factors and consult with experts to ensure the appropriate steel sheets are selected for optimal magnetic shielding.

- Q: Can steel sheets be used for electromagnetic shielding?

- Yes, steel sheets can be used for electromagnetic shielding. Steel is a highly conductive material, which means it can effectively divert and absorb electromagnetic waves, preventing them from penetrating through the shield. This makes steel sheets an excellent choice for applications requiring electromagnetic shielding, such as electronic devices, power transformers, and MRI machines.

- Q: What's the corrosion resistance of hot-dip galvanized steel sheet?

- The corrosion resistance of galvanized steel sheet in natural environment is acceptable. The biochemical pond in the sewage treatment plant is strong in acidity, and the zinc is not acid resistant. It is very different from the galvanized sheet with the uncoated steel sheet.

- Q: Should the carbon fiber reinforce the steel bar on the side of the beam?

- Chemical anchorage, chemical anchor bolt, carbon fiber reinforcement, steel reinforcement, fill crack traps, rust, concrete cutting drilling and repairing concrete foundation reinforcement etc..

Send your message to us

Wuyang 1E1839 plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords