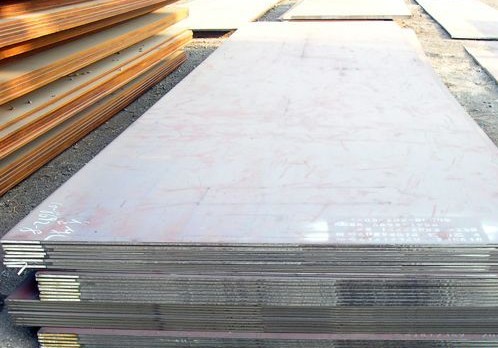

A515Gr70 steel production in Wugang

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SA515Gr70belonginlowcarbonsteelpressure vessels,performASMEstandards,Wugang2006R & Dproduction,is widely used inpetroleum, chemical, power plants,boilers and otherindustries for the productionreactors,heat exchangers,separators,ballcans,gas tanks, nuclearreactor pressure vessel,boiler drum,hydropowerhigh pressurepipes,water wheelsvoluteother equipment and components.

1.SA515Gr60, SA515Gr70, SA516Gr60, SA516Gr70, SA516Gr60N, SA516Gr70Nthickness≤1.5in, (40mm)steelis usuallysupplied inrolled condition, steelcan also benormalized oreliminate stress,or normalizedstress relievingorders.

2thickness> 1.5in. (40mm)steelshould benormalized.

4, ifapprovedby the demand side,allows the use oflarger than thecooling ratein the airto improve thetoughness,butas long as thesubsequentsteel1100-1300°F (595-705 ℃)within a range oftempering.

Q245R、Q345R、Q370R、16MnDR、15CrMoR、09MnNiDR、SA285GrC、19Mn6、P355GH、15Mo3、SPV355、15MnVR、14Cr1MoR、SA515Gr60/70、SA516Gr60/70、A48CPR

SA515Gr60 / 70is widely used inpetroleum, chemical,power plants,boilers and otherindustries for the productionreactors,heat exchangers,separators, tank, notank, nuclearreactor pressure vessel,boiler drum,hydropowerhigh pressurepipes,waterscrollwheeland other equipment andcomponents.

Grade thickness width length remarks

SA515Gr60 8 2300 10000 FourcutGuaranteed

SA515Gr60 185 3815 10322

A515Gr60 25 2400 12000 FourcutGuaranteed

SA515Gr60 30 2500 11400

SA515Gr60 36 2300 10000 FourcutGuaranteed

SA515Gr60 40 2520 8400

SA515Gr60 50 2300 10000 FourcutGuaranteed

SA515Gr60 60 2000 10000

SA515Gr60 80 2560 10800

SA515Gr60 100 2700 8900 FourcutGuaranteed

SA515Gr60 120 2550 10500

SA515Gr60 200 2550 3330

- Q: Are steel sheets suitable for food storage applications?

- Yes, steel sheets are highly suitable for food storage applications. They are durable, resistant to corrosion, and provide a hygienic and safe storage environment for food products. Steel sheets can maintain the freshness and quality of food while protecting it from external contaminants.

- Q: Do steel sheets have any magnetic properties?

- Yes, steel sheets can have magnetic properties. The magnetic properties of steel sheets depend on the composition and processing methods used. Some steels, such as carbon steels, are not inherently magnetic, while others, such as stainless steels, can exhibit magnetic behavior.

- Q: What is the average lead time for manufacturing steel sheets?

- The manufacturing of steel sheets can have varying lead times based on a multitude of factors including order size and complexity, manufacturing processes utilized, and the current demand and capacity of the production facility. Generally, lead times can range from a few weeks to a few months. For smaller, standard-sized orders, the lead time is typically shorter, spanning from 2 to 6 weeks. This duration allows for the acquisition of raw materials, processing, and quality control procedures to ensure the final product meets the necessary specifications. Conversely, larger or more intricate orders necessitate longer lead times. This is because additional time is required to customize the steel sheets according to specific dimensions, finishes, or treatments. In such instances, lead times can extend to several months. External factors such as supply chain disruptions, unforeseen delays in raw material procurement, or fluctuations in demand can also impact lead times. Consequently, it is prudent to consult the manufacturer or supplier of the steel sheets to obtain an accurate estimate of the lead time based on the particular requirements of the order.

- Q: What is the process of forming corrugated steel sheets?

- The process of forming corrugated steel sheets involves passing flat steel sheets through a series of rollers that have corrugated patterns. These rollers apply pressure to the steel sheets, creating the desired corrugated shape. This process increases the strength and durability of the steel sheets, making them suitable for various applications such as roofing, siding, and packaging.

- Q: What is the difference between a perforated and woven steel sheet?

- A metal sheet with holes or perforations evenly spread across its surface is known as a perforated steel sheet. These holes can come in various shapes and sizes, including round, square, or slotted. Perforated steel sheets are commonly utilized in situations where there is a need for airflow, visibility, or drainage, such as in architectural design, filtration systems, and acoustic panels. The primary advantage of perforated steel sheets is their ability to offer these functionalities while still maintaining their structural integrity. Contrarily, a woven steel sheet is created by intertwining steel wires in a specific pattern. This interlacing results in a mesh-like structure where the wires form intersecting horizontal and vertical lines. Woven steel sheets are frequently employed in applications that require strength, durability, and security, like fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their capability to provide a high level of strength and security due to the tightly interwoven wires. In conclusion, the primary distinction between perforated and woven steel sheets lies in their distinctive structures and functionalities. Perforated steel sheets consist of evenly dispersed holes across their surface, offering advantages such as airflow and visibility. On the other hand, woven steel sheets are formed by intertwining steel wires to create a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the given application.

- Q: Can steel sheets be used for noise reduction purposes?

- Yes, steel sheets can be used for noise reduction purposes. Steel has excellent soundproofing properties due to its density and ability to dampen vibrations. It is often used as a barrier material in construction projects to reduce noise transmission between different areas.

- Q: What are steel sheets used for?

- Steel sheets are commonly used for various applications such as construction, manufacturing, automotive, and aerospace industries. They are utilized in building structures, roofing, cladding, and fabrication of machinery, equipment, and vehicles. Additionally, steel sheets can be used for making appliances, electrical enclosures, storage tanks, and many other industrial and commercial purposes.

- Q: Are steel sheets suitable for electrical applications?

- Yes, steel sheets can be suitable for electrical applications. They have good electrical conductivity and can be used for applications such as electrical enclosures, panels, and grounding components. However, it is important to consider factors like insulation and corrosion resistance when using steel sheets in electrical applications.

- Q: What are the different sheet metal welding techniques for steel sheets?

- There are several sheet metal welding techniques commonly used for steel sheets, including spot welding, seam welding, and TIG welding. Spot welding involves joining two metal sheets by applying pressure and heat at specific points, creating a strong bond. Seam welding, on the other hand, involves continuously welding along the length of a joint, creating a continuous welded seam. TIG welding, also known as tungsten inert gas welding, uses a non-consumable tungsten electrode to create an arc that melts the metal, forming a weld pool that fuses the steel sheets together. Each technique has its own advantages and is chosen based on the specific requirements of the project.

- Q: How do steel sheets compare to aluminum sheets?

- Steel sheets and aluminum sheets have distinct properties that make them suitable for different applications. Steel sheets are generally stronger and more durable than aluminum sheets, making them ideal for heavy-duty construction, automotive, and industrial applications. On the other hand, aluminum sheets are lighter, have better corrosion resistance, and offer excellent thermal conductivity, making them suitable for aerospace, marine, and electrical applications. Ultimately, the choice between steel and aluminum sheets depends on the specific requirements of the project or application at hand.

Send your message to us

A515Gr70 steel production in Wugang

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords