wood plastic composite outdoor decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

outdoor wpc decking supplier, china factory, Engineered Flooring Type

1Low maintenance

2Widely used indoor and outdoor

3Cert

outdoor wpc decking supplier, china factory, Engineered Flooring Type

1Low maintenance

2Widely used indoor and outdoor

3Certificated

Specification of outdoor wpc decking supplier, china factory, Engineered Flooring Type

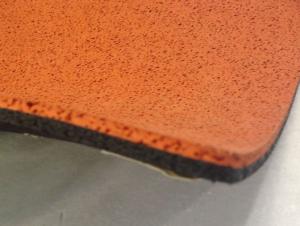

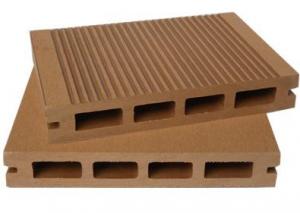

1) Elegant nature wood grain texture and touch

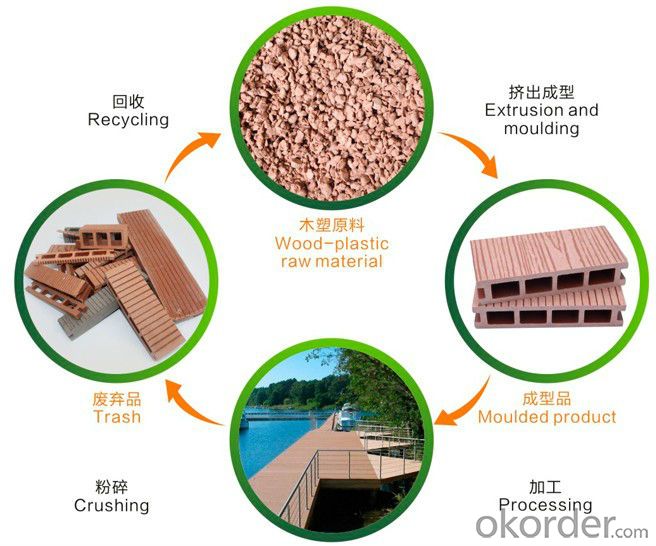

2) Eco-friendly, high-recyclable, green material

3) No cracking, warping, and splitting

4) Water/Moisture-proof, Corrosion-resistant

5) Low maintenance and no painting

6) Easy to install, clean

7) Weather resistant, suitable from -40 to 60

8) High degree of UV and color stability

Item | outdoor wpc decking supplier, china factory, Engineered Flooring Type |

Size | 150*25mm,146*32mm,142*35mm,140*40mm,140*25mm,135*27mm etc. |

Length | As your choice |

Color | black, coffee, brown, gray, white ,redwood etc. optional |

Surface | Smooth,Brushed,Scratched,Grain&Sanded optional |

Component | 50% wood fibers +45% HDPE+ 5% chemical additives |

Warranty period | 15 years |

Certificate | CE,ISO,FSC,SGS |

Packages | PE Film+WPC Pallet(length of 0-2.2m)+Wood Pallet(length>2.2m) |

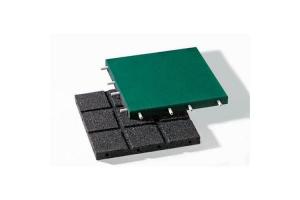

Applications | Garden,Lawn,Balcony,Corridor,Garage, Pool&SPA Surrounds,Boardwalk,Playground |

This type can be used in outdoor ground, trestle road and garden path, enjoying great superiority in the outdoor decking of courtyard, park, garden community, waterscape, trestle and plank road,etc

Pictures:

Color:

Material

- Q: Gym rubber floor, rubber floors and plastic floor

- Without scratches on the dance floor is divided into two types: children dance and dance is a special dance adult dance dedicated, in color and thickness is limited (children dance special color dark gray, dark green, light gray, green gray, blue towel) (adult dance special color dark gray, blue. Gray, oak, maple, grey, black, dark green)

- Q: What are their strengths and weaknesses?

- PVC floor is good, rubber is not good for the eldest sister, and disinfection is not good, and the relatively slippery rubber

- Q: Does the gym floor belong to plastic floor?

- The PVC: material with a high concentration of multi-layer PVC material composition, non slip surface embossing, increase abrasion resistance and anti scratch ability. The utility model is suitable for indoor table tennis courts, badminton courts, basketball, tennis, handball, volleyball and gymnasium.P U: the product is made of adhesive poly carbamate (PU) and a fat resin according to a certain proportion mixed batch according to the site requirement apply on the surface layer are bonded into a sports field without seams, elastic, usually the thickness is 4 5mm, can be used as advantages: anti-skid and anti electrostatic floor. Disadvantages: the surface layer is relatively high requirements on the ground, the foundation is smooth, no cracks, must do the waterproof asphalt foundation. There are differences in the maintenance construction, the old color is obvious. Mainly used in basketball, tennis, table tennis, volleyball, badminton courts and other indoor sports venues.

- Q: Rubber floor harmful to the human body

- PVC is indeed able to secrete a toxic and harmful gases, with a certain degree of volatility

- Q: The difference between rubber floor and PVC floor

- Other answerRubber floor, as the name implies, which contains plastic and rubber, the floor first appeared in Europe, such as Gerflor's bright excellent series of rubber ground material, this material is mainly comprehensive advantages of plastic flooring and rubber flooring. In China, this kind of material is the main ingredient of waste rubber or plastic, with some in the majority is to act as a rubber flooring sold to customers, this is not in vain. The majority of dealers are doing so, take tens of dollars of domestic rubber flooring as one hundred or two hundred dollars to sell the rubber floor, this material fire performance is poor, it is not mature products.Give you a suggestion, if you want to buy rubber flooring, try to choose European imports of products. Or buy a plastic floor or rubber floor.

- Q: Rubber floor price per square meter

- Rubber floor price per square meter in the 50-150 yuan per square meter. Rubber flooring, as the name implies, is the floor of natural rubber and other synthetic rubber. In appearance, its color is bright, gives a very spiritual sense, for the movement of people is refreshed. And it is also like the texture of soft rubber, when others in the sport on the rubber floor, there will be unlimited power and bounce, very suitable for sports as a venue for sports. At present, the development of domestic rubber flooring

- Q: EPDM rubber flooring installation construction what are the precautions

- The concrete can not contain any additives or hardening agent; rut, induration, concave, crack, or openings and other phenomena may not appear on the site.Water, water circle, the ingredients, mixing site clean up, pay attention to keep the ingredients and the surrounding smooth clean ground. Taiwan said the burden of ingredients, mixing barrels, mixers, barrels board, pliers, etc.. Each part should be in strict accordance with the mixing of raw materials. 3, the concrete must be wet through 7 days, the 28 day of emotional maintenance treatment;

- Q: Where is suitable for rubber flooring

- Floor decoration is an important part of the building decoration. The general outline of the ground decoration materials, generally have the following types:(1) floor paint or floor wax;(2) ceramic floor (all kinds of ceramic tiles, ceramic tiles, etc.);(3) the ground stone (marble, granite, stone floor);(4) textile fabrics (wool carpet, chemical fiber carpet, etc.);

- Q: PVC floor which is divided into several models? What is the difference between the rubber floor?

- Color difference: rubber floor coloring is difficult, because the rubber suction color is very strong, so most of the rubber floor color is single; and very much PVC floor color, can be any combination, can give designers more options.

- Q: Rubber floor can be used for interior decoration?

- Therefore, this product has the dual function of purifying air and protecting leather. Madeleine super purification treasure: the product is sprayed directly on the plywood, MDF, wood not paint on wood board surface, forming a layer of air purification membrane on the surface, can continue to produce formaldehyde scavenging substances penetrate into the wood, to remove harmful objects. Madeleine air purification treasure: This product uses the patented technology, spraying the surface covered with a lot of air catalyst for this product at room temperature in the air, the water can not be changed into negative ions in the water, but if in contact with air catalyst can put water molecules into the negative ion water, like water with dissolved salt like ability it is permanent and effective. Air pollutants mainly refers to formaldehyde, benzene, radon, VOC, dust, bacteria, viruses, etc., by the quality inspection departments: Ma Delan, air purification treasure on the above harmful substances removal rate of more than 80%,

Send your message to us

wood plastic composite outdoor decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords