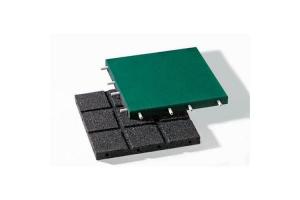

Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Despription of Track Pad 1000 Series

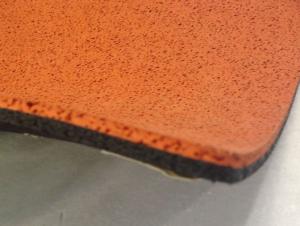

Track Pad 1000 Series are made of 100% recycled rubber granules.

Track Pad 1000 Series are manufactured by factory with the precasting process and 100% recycled rubber roll. The prefabricate rubber roll are equal thickness, balanced elasticity and smooth surface. Besides, it's convenient for transport and carry. It needs a few of labours and easy tools in the process of installation .There in no need of extra large pave equipments. It also reduce the effects of machinery inconvenience and meet the needs of all kinds of tracks' installation.

Features of Track Pad 1000 Series

Equal thickness, balanced resilience

Smooth surface

Excellent ventilate and water seepage abilities

Fine rating of temperature , cold-resistant and weather resistance

Environmental friendly, non-toxic

Recycled and pollution-free

Application of Track Pad 1000 Series

Underlayer of all kinds of athletic tracks.

Parameters of Track Pad 1000 Series

Density (kg/m3):850 900

Hardness (Shore A ): 58 63

Length (m): 10/15/20m ±5cm

Width (m):1m/1.25m ±5mm

Thickness (mm):7-12mm ±0.3mm (adviced thickness )

- Q: How about rubber flooring Rubber floor

- (4) textile shop (wool carpet, chemical fiber carpet, etc.); (5) wooden floor (log floor, composite wood floor); (6) synthetic material floor tiles (stone plastic floor, rubber flooring, floor leather, etc.)

- Q: Rubber flooring can be used for home decoration

- Yes, but rubber is also divided into many kinds of materials and many kinds of

- Q: What is the meaning of self leveling rubber floor

- Self leveling is to solve the problem of horizon, paving the floor of the need for rubber flooring, if there is a small grain of sand on the ground did not clean up, it will make the laying of the floor uneven. In this case, often make the floor is not wear-resistant, uneven aesthetic enough, look ugly.

- Q: Does the gym floor belong to plastic floor?

- As for the plastic floor is a general concept, the usual meaning of plastic, including PVC, PU, silicon PU, acrylic acid and EPDM.

- Q: What tools to clean the rubber floor

- Ground cleaning and maintenance methods of rubber: (a) used in the cleaning and maintenance of tools and materials, tools and equipment: 1: (1) the electric grinding cleaning machine, equipped with a flat brush cleaning wheel, nylon cleaning pad (coarse, medium and fine); (2) vacuum cleaner and water suction machine; (3) mop;

- Q: Rubber flooring, how much a square! Do you know?

- More than 10 yuan per square meter to more than 400 yuan per square meter of imports are. The main difference in the price of plastic floor wear-resisting layer.Is it possible to solve your problem?

- Q: How to deal with the paint on the rubber floor

- The official name is thinner, thinner or solvent oil, usually colorless transparent liquid, commonly known as banana water.

- Q: The basketball court is a rubber floor, there are a lot of black dirt on the top, washing powder and hot water are not working, I would like to ask which brother know what method can be removed?

- It depends on what dirt you get. Here are some common treatments:Oil: local oil, aqueous degreasing agent solution poured directly on the towel wipe; a large area of oil, will be the only special water-based degreasing agent in 1:10 diluted with wiping machine with red disc cleaning speed.Black offset: spray cleaning wax with high speed polishing machine polishing pad with white polishing. For a long time of black offset printing, you can remove the powerful black offset printing agent directly on the towel to wipe.Glue or chewing gum: with a professional powerful adhesive directly onto the towel wipe wipe. Cleaning agent: water-based degreasing agent, spray cleaning, maintenance wax strong black offset removing agent, in addition to adhesive strength.

- Q: How to identify the difference between oak flooring and rubber wood flooring?

- Oak is mostly made of furniture and flooringRubber wood is furniture, rarely do the floor. With the oak oak floor sitting posing

- Q: What is the production process of rubber flooring

- Self leveling cement ground leveling, dry ground, surface grinding, surface cleaning, size, material beach open 24 hours after the start of pavement, dry rubber cutting place, scraping, put the material sticking board, smooth compaction, welding, repair, cleaning, acceptance, qualification, use. The need for professional installation of plastic floor laying

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Western Europe; North America; Oceania; Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords