Weldable EPDM Waterproof Sheet Width1~4m Thickness 1.2mm~2.0mm for Basement Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

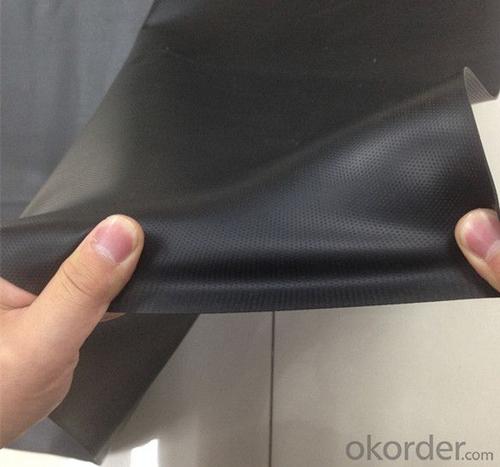

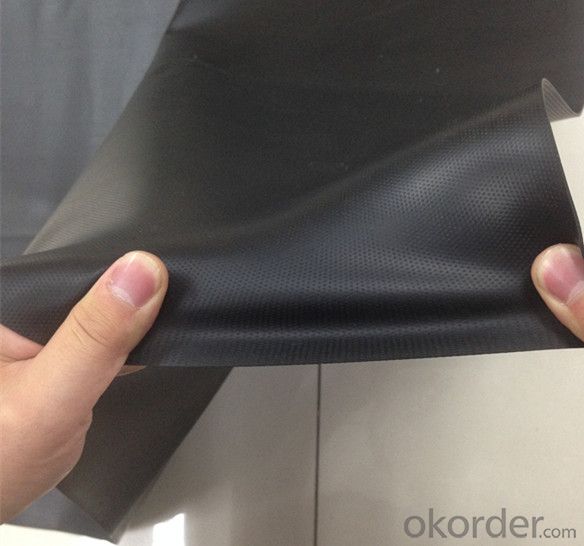

Weldable EPDM Rubber Waterproof Membrane

Product Instruction:

Durability and ease of installation are two of the key reasons . Single ply EPDM Roof systems are becoming commonplace in today flat roofing market. EPDM membrane is a flexible rubber material available in 45 mil, 60 mil and 90 mil thicknesses. With its superior flexibility, resistance to fire and high strength, EPDM can be applied in all sorts of climates.

Weldable EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

6. How long do we usually reply your request?

We always reply our customer within 24 hours.

Photos:

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Using a different grammatical structure and expressions: Indeed, breeze block surfaces can benefit from the application of a waterproofing membrane. These concrete blocks, also known as breeze blocks, are commonly utilized in construction due to their porous nature. This porosity allows water to infiltrate the blocks, which can potentially lead to dampness or water-related harm within the building. To counteract this issue, the surface of the breeze blocks can be treated with a waterproofing membrane. A waterproofing membrane is a thin layer of material specifically designed to impede water penetration. It acts as a protective barrier, preventing water from seeping into the breeze blocks and safeguarding the underlying structure against moisture damage. This membrane is typically applied in either liquid or sheet form and securely adhered to the surface of the breeze blocks using an appropriate adhesive. Prior to applying the waterproofing membrane, it is crucial to adequately prepare the surface of the breeze blocks. This may involve thorough cleaning to ensure the absence of loose debris or contaminants. Additionally, any existing cracks or gaps in the breeze blocks should be addressed and repaired prior to the membrane application. This meticulous preparation is necessary to achieve a seamless and effective waterproofing system. It is important to note that the selection of the appropriate waterproofing membrane depends on the specific requirements of the project and the conditions to which the breeze block surface will be exposed. There are several types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, or cementitious coatings. To determine the most suitable membrane for your particular application, it is advisable to consult with a professional or the manufacturer. In conclusion, the utilization of a waterproofing membrane on breeze block surfaces is an effective means of preventing water penetration and safeguarding the underlying structure against moisture damage. Proper surface preparation and careful consideration of the appropriate membrane type are vital elements in achieving a successful waterproofing solution.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels. Waterproofing membranes are designed to prevent the penetration of water and can be effective in areas where groundwater levels are high. However, it is important to ensure that the membrane is properly installed and meets the specific requirements of the site conditions to ensure optimal performance.

- Q: Can a waterproofing membrane be applied in cold weather?

- Applying a waterproofing membrane in cold weather is possible. However, there are certain factors to consider. It is essential to choose a membrane specifically designed for cold weather use, as some may not work well in low temperatures. The curing process of the membrane can be affected by cold weather, so it is crucial to adhere to the temperature limitations and application techniques provided by the manufacturer. Before applying the membrane, the surface must be clean and dry to prevent interference from moisture or ice. In cold weather, the membrane may take longer to cure and reach its maximum performance. Therefore, it is advisable to allow ample time for drying and curing before exposing it to water or other stressors. Additionally, it is worth noting that extreme cold temperatures can hinder the installation process and the overall effectiveness of the waterproofing system. Therefore, it is recommended to seek guidance from a professional waterproofing contractor experienced in working under such conditions to ensure the best outcomes.

- Q: Can a waterproofing membrane be used in steam rooms?

- Indeed, the utilization of a waterproofing membrane within steam rooms is possible. This specialized membrane is crafted to obstruct water infiltration and is commonly employed in areas where moisture is prevalent, such as bathrooms, showers, and steam rooms. The primary function of this membrane is to create a barrier that hinders water vapor from penetrating the underlying structure and inducing harm. In the case of steam rooms, where elevated levels of humidity and moisture are abundant, the implementation of a waterproofing membrane is imperative in safeguarding the walls, floors, and other surfaces from water damage and the growth of mold. It is of utmost importance to select a waterproofing membrane that is explicitly designed for environments with high moisture content, such as steam rooms, in order to ensure sufficient protection and durability. Furthermore, for the membrane to effectively fulfill its purpose within a steam room setting, proper installation and adherence to the guidelines provided by the manufacturer are essential.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Indeed, wastewater facilities necessitate a strong safeguard against the potentially harmful and corrosive effects of wastewater. By employing a waterproofing membrane, the infiltration of water, which can result in structural harm, deterioration, and contamination of surrounding areas, can be effectively prevented. Waterproofing membranes act as a barrier, shielding the facility's walls, floors, and foundations from the intrusion of water and moisture. This serves to uphold the structure's integrity, prevent leaks, and guard against corrosion stemming from the presence of chemicals in wastewater. Furthermore, certain waterproofing membranes not only safeguard against water and chemical damage but also exhibit resistance to UV rays, high temperatures, and freeze-thaw cycles. This is particularly significant for wastewater facilities situated in regions characterized by extreme weather conditions. All in all, employing a waterproofing membrane in wastewater facilities is a dependable and efficient means of ensuring long-term protection against water damage, preserving the structural integrity, and augmenting the facility's durability.

- Q: Can waterproofing membranes be applied on roofs?

- Roofs can have waterproofing membranes applied to them, a practice commonly employed in the construction industry to add an extra layer of protection against water infiltration. These membranes, typically composed of synthetic materials like PVC, TPO, or EPDM, possess high resistance to water and effectively prevent leaks and water damage on roofs. Applying waterproofing membranes on roofs is a proven method for enhancing the longevity and durability of the roofing system, particularly in areas prone to heavy rainfall or extreme weather conditions. Moreover, waterproofing membranes are flexible and can be easily installed on various roofing materials such as concrete, metal, or asphalt shingles. Consequently, if you desire a watertight roof and wish to safeguard your property from water-related problems, the utilization of waterproofing membranes offers a dependable and efficient solution.

- Q: How does a waterproofing membrane handle water pressure from below?

- A waterproofing membrane is designed to handle water pressure from below by creating a barrier that prevents water from penetrating through it. The membrane acts as a protective layer, preventing water from seeping into the structure or area that it is applied to. The membrane is typically made from materials such as rubber, PVC, or bitumen, which have excellent water-resistant properties. These materials are flexible and can stretch to accommodate movement in the structure, ensuring that the membrane remains intact even under dynamic conditions. When water pressure from below is applied, the waterproofing membrane resists the force exerted by the water and prevents it from entering the structure. The membrane is installed in such a way that it covers the entire area that needs protection, ensuring a seamless and continuous barrier against water intrusion. Furthermore, waterproofing membranes often have additional features, such as reinforcement layers or fabric backings, which enhance their strength and durability. These features help the membrane withstand higher water pressures and minimize the risk of leaks or water damage. It is important to note that the effectiveness of a waterproofing membrane in handling water pressure from below depends on various factors, such as the quality of the membrane, proper installation techniques, and the specific conditions of the site. Adequate surface preparation, correct membrane application, and regular maintenance are essential to ensure the long-term performance of the waterproofing system. Overall, a waterproofing membrane is designed to handle water pressure from below by creating a robust barrier that prevents water ingress, protecting the structure or area from potential water damage.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Yes, a waterproofing membrane can definitely be used in government or municipal projects. In fact, it is often a crucial component in the construction or renovation of various infrastructure projects such as roads, bridges, tunnels, and buildings. Waterproofing membranes help to prevent water infiltration, which can cause damage to the structure and compromise its integrity. By using a waterproofing membrane, government and municipal projects can ensure the longevity and durability of their infrastructure, reducing the need for costly repairs or replacements in the future. Additionally, waterproofing membranes can also contribute to energy efficiency by preventing moisture intrusion, thus reducing the potential for mold growth and improving insulation properties. Overall, the use of a waterproofing membrane in government or municipal projects is highly recommended to enhance the lifespan and functionality of the infrastructure.

- Q: Can a waterproofing membrane be used in hospitals or healthcare facilities?

- Yes, a waterproofing membrane can be used in hospitals or healthcare facilities. In fact, it is highly recommended to use waterproofing membranes in these settings due to the critical need for maintaining a clean and hygienic environment. Waterproofing membranes are typically applied on floors, walls, and ceilings to prevent water or moisture infiltration, which can lead to mold growth, deterioration of building materials, and compromise the structural integrity of the facility. By using waterproofing membranes, healthcare facilities can effectively protect against water damage, facilitate easier cleaning and maintenance, and prevent the growth of bacteria and other harmful microorganisms. Additionally, waterproofing membranes can also help in managing moisture levels, thereby reducing the risk of slips and falls, which is especially crucial in areas where patients, staff, and visitors frequent. Overall, waterproofing membranes are a valuable asset in ensuring the safety, durability, and cleanliness of hospitals and healthcare facilities.

- Q: How does a waterproofing membrane handle construction joints?

- Construction applications require the use of a waterproofing membrane to prevent water from penetrating the structure. Specifically, in concrete structures where construction joints are commonly found, the membrane is engineered to effectively address these areas. During the construction process, joints are created to allow for movement between different sections of the structure. Unfortunately, these joints can also be vulnerable points where water can potentially infiltrate. To tackle this concern, waterproofing membranes are installed to ensure that these joints remain watertight. Different methods are employed to handle construction joints with waterproofing membranes. One popular approach is to directly apply the membrane over the joint, extending it beyond the joint edges. This creates a continuous waterproof layer that covers both the joint and its adjoining areas. Another technique involves the use of specially designed joint tapes or strips that are embedded within the membrane. These tapes or strips, typically made of materials like rubber or PVC, are placed directly over the joint before the membrane is applied. They serve as an additional layer of protection, enhancing the waterproofing performance of the membrane at the joint. Additionally, there are specialized waterproofing systems available that include pre-formed joint sealants. These sealants are designed to fit snugly into the joint, providing a tight seal against water intrusion. The membrane is then installed over the joint, ensuring comprehensive waterproofing coverage. In summary, a waterproofing membrane is specifically engineered to effectively handle construction joints by offering a durable and efficient barrier against water penetration. Whether through extending the membrane over the joint, utilizing joint tapes or strips, or incorporating pre-formed joint sealants, these membranes guarantee that construction joints remain watertight, thus safeguarding the structure from potential water damage.

Send your message to us

Weldable EPDM Waterproof Sheet Width1~4m Thickness 1.2mm~2.0mm for Basement Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 220000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords