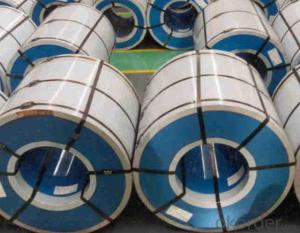

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | DX51D | Thickness: | 0.13mm-0.8mm,0.13-0.7mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | HUAYE224 |

| Type: | Steel Coil | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Constuction, Furniture, transport, electrical equipment,ect. | Special Use: | Wear Resistant Steel | Width: | 800mm-1250mm,1000mm, 1200mm,1250mm |

| Length: | As the width and thickness | Color: | Sea blue, white grey, crimson, green or as RAL | Zinc coating: | 40-100gsm |

| Coil Weight: | 3-6 Tons | Coil ID: | 508mm | Back coating thickness: | 5-7um |

| Top coating thickness: | 13-20um |

Packaging & Delivery

| Packaging Detail: | seaworthy expot package |

| Delivery Detail: | 15-20 days after receiving deposit by T/T |

Specifications

Wear resistant steel plate

1.Competitive price and High quality

2.Anti-corrosion

3.Width:800-1250mm

4.Thickness:0.13mm-0.7m

Business Products

Color coated galvanized steel coil (prepainted galvanized steel coil)

Shandong Huaye colour steel coil supplier

Wear resistant steel plate

PPGI sheet metal steel gauge

Galvanized steel coil (znc coating steel coil)

Galvalume steel coil (alu-zinc coating steel coil)

Cold rolled steel coil

Color coated galvanized steel coil

Characteristic

Thickness: 0.13mm-0.8mm

Width: 914mm-1250mm

Zinc coating: 40-150gsm

Color: Red, green, orange, white, blue, or as RAL code

Coating thickness: top: 13-20um; back: 5-7 um

Coil ID: 508mm10mm

Coil weight: 3-6 metric tons

Base material: Galvanized steel coil, galvalume steel coil, cold rolled coil, ect.

Packing: 4 eye bands and 4 circumferential bands in steel, galvanied metal fluted rings on inner and outer edges, galvanized

metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Port of loading: Qingdao, Tianjin, Shanghai and so on

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- There is an iron powder reinforced concrete flooring that improves abrasion resistance. However, you cannot get the tensile strength enhancement that is possible with rebar.

- Q: How do steel coils contribute to the marine equipment industry?

- Steel coils contribute to the marine equipment industry by being a crucial component in the manufacturing of various marine equipment such as ships, boats, and offshore structures. These coils are used in the construction of hulls, decks, and other structural parts, providing strength, durability, and corrosion resistance. Additionally, steel coils are used in the production of marine equipment components like pipelines, storage tanks, and marine engines, ensuring their reliability and performance in harsh marine environments.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Brass is slightly softer than annealed steel. Both can be reloaded, once or maybe even twice. But STEEL has a tendency to WORK HARDEN, becoming brittle. Which is why it's used for tools and other applications where work hardening is a plus. It's actually designed to do that. Brass does not work harden, because it is a different sort of metal. That's the main reason.

- Q: How are steel coils used in the production of industrial storage tanks?

- Steel coils are commonly used in the production of industrial storage tanks due to their superior strength and durability. These coils are typically made from high-quality steel that is rolled into a coil shape, allowing for easy transportation and handling. In the production process, steel coils are first uncoiled and flattened to create sheets of steel. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are welded or bolted together to create the tank's body, which is designed to withstand high pressure and heavy loads. The use of steel coils in the production of industrial storage tanks offers several advantages. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and are resistant to corrosion. This is particularly important for storage tanks that may contain corrosive substances or be exposed to harsh environments. Additionally, the flexibility of steel coils allows for customization of the tank's design and size. This is particularly beneficial in industries where storage requirements can vary significantly, such as the oil and gas industry. Steel coils can be easily cut and formed into various shapes and sizes, enabling the production of storage tanks that meet specific storage needs. Furthermore, steel coils can be easily transported and stored, making them a cost-effective choice for the production of industrial storage tanks. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. Overall, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their use ensures that the tanks can safely store and protect various substances, making them essential for a wide range of industries.

- Q: What is the role of steel coils in the supply chain?

- Steel coils play a crucial role in the supply chain as they are used for a variety of purposes, such as transportation, storage, and manufacturing. They serve as a convenient and efficient way to transport large quantities of steel, ensuring that it reaches its destination safely and in optimal condition. Additionally, steel coils facilitate storage by allowing for easy stacking and organization, maximizing space utilization. Moreover, they are a primary raw material for various industries, especially manufacturing, where they are used in the production of a wide range of products, including automobiles, appliances, construction materials, and more.

- Q: What is the role of steel coils in the production of pipes and tubes?

- Steel coils play a crucial role in the production of pipes and tubes as they serve as the primary raw material. These coils are unwound and undergo various processes such as cutting, bending, and shaping to form the desired pipe or tube shape. The steel coils provide the necessary strength, durability, and structural integrity to the final product, ensuring that pipes and tubes can withstand high pressure, corrosion, and other demanding conditions.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q: I have a set of Stainless steel pots and pans. Everything is sticks to them. What must I do so things don't stick?

- I only cook acidic foods in stainless steel or tomato sauces, Marinara sauces. Or sauces with wine in it. Because stainless steel is good with those kind of foods. Maybe you should use a little more fat, butter or Olive oil. And don't get the pan too hot, ( I don't care what other ppl say). Sometimes I heat up the pan and put a pat of butter in the pan to judge how hot it is. Once the butter starts sizzling or sputtering, the pan has reached the right temperature. Don't let the butter burn, the pan is too hot if the butter scorches. You can put a tablespoon (or less) olive oil in the skillet first and then a pat of butter; let them blend together. The oil will help keep the butter from burning.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process called galvanization. In this process, the steel coils are submerged in a bath of molten zinc, creating a protective zinc coating on the surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus inhibiting corrosion.

- Q: Can steel coils be coated with chemical-resistant materials?

- Yes, steel coils can be coated with chemical-resistant materials. These coatings are designed to protect the steel surface from the corrosive effects of chemicals or other harsh substances. The chemical-resistant coating forms a barrier that prevents the chemicals from directly interacting with the steel, enhancing its durability and longevity.

Send your message to us

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords