Wafer Type Eccentric Butterfly Valve With PTFE Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 300 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wafer Type Eccentric Butterfly Valve With PTFE Sealing

The Butterfly Valve Standard

Designed: API609, ASME B 16.34, AWWA C 504, BS EN593

Face to Face: API 609, AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASME B 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BS EN 12266, ISO 528

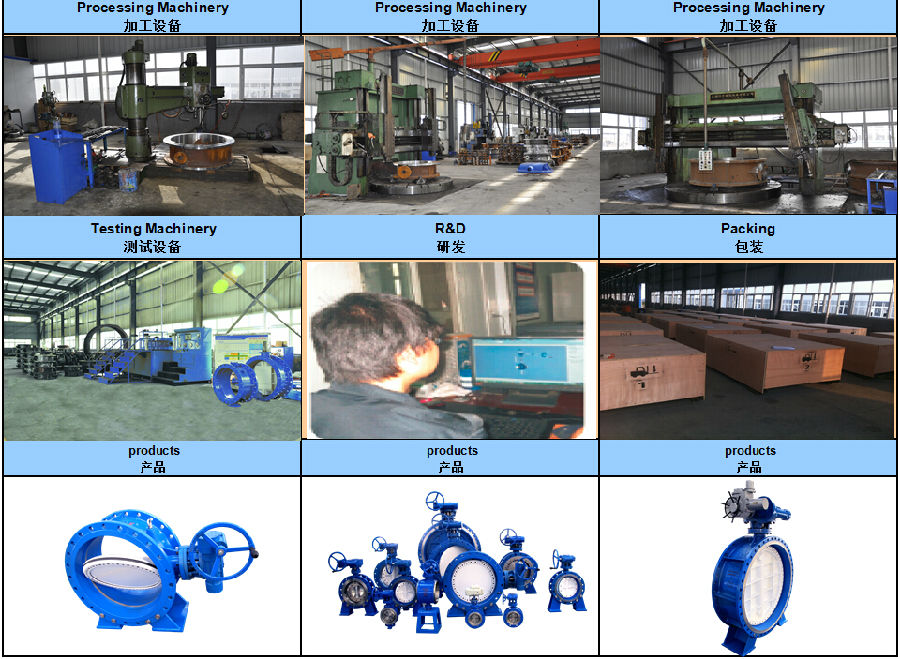

Materials Choose

Body Materials: WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials: WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Seat Materials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure: PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Worm gear/Electric/Pneumatic

Field of Application: Electric /Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Delivery: within 15-30days after receipt of at sight L/C or 30% as advance payment by T/T

Butterfly Valve Packing: Seaworthy packing:

1. Single Butterfly Valve is packed with foam plastic bag.

2. Put sponge in each floor

3. Electric or pneumatic actors will Individual packaging it with wood box.

4. Export Wooden Packing

5. We can pack according to specific customer requests.

6. Customers’ logos are available on package.

7. Design and manufacturing the wood box to save the sea cost if needed .

- Q: What is the meaning of the D341*5-10 / 16ZB1 turbine butterfly valve flange said?

- D341 is flanged connection center plate butterfly valve under pressure 1.0MPa-1.6MPa ZB1 rubber soft seal

- Q: What's the difference between D71X-16 and D71H-16 butterfly valves?

- D71X-16 and D71H-16 butterfly difference is that the cut-off is not the same, the latter is stainless steel seal, corrosion resistance, friction, acid or impurities can be medium fluid. The former is rubber sealed, only through the general temperature of the medium, not acid, with more, you can ask Luoyang crown Ning

- Q: Does the pneumatic butterfly valve need electricity?

- Definitely need control, so be sure to have electricity. You can control the switch on and off. If necessary, this valve can contact me.

- Q: Fire, the signal butterfly valve flange connection or welding?

- 1, do a good job with flange.2, flange (Flange), also known as flange, flange plate or edge. A flange is a part that is connected between the pipe and the pipe, used for the connection between the ends of the pipe. It is also used for the flange on the entrance and exit of the equipment. It is used for the connection between the two devices, such as the reducer flange. Flange connection or flange joint means that the flange, the shim and the bolt are mutually connected as a group of three detachable sealing structures. Pipe flanges are flanges used for piping in pipe installations. They are used on equipment and refer to the entrance and exit flanges of the equipment. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Sub threaded flange connection (threaded connection), flange welding flange and flange clamp. Flanges are used in pairs. Low pressure pipes can be made of wire flanges and welded flanges with pressures of more than four kilograms. Add a gasket between the two flanges and secure with bolts. Different pressure flange thickness is different, they use the bolt is also different. Water pump and valve, and in the pipe connection, these equipment parts of the equipment also made corresponding flange shape, also known as flange connection. Any connecting parts that are bolted and closed in the vicinity of the two planes are generally referred to as flanges, such as the connections of the ventilation ducts, which can be called flanges". However, this connection is only part of a device, such as flanges and pumps connected, it is not good to call the water pump flange parts". Relatively small, such as valves, can be called flanges".3, also known as welding: welding, melt, is a kind of heating, high temperature or high pressure way of metal or other thermoplastic materials such as plastic manufacturing process and technology.

- Q: How does the pneumatic butterfly valve control the angle of opening?

- This is really not good, control seems to be pneumatic defects, can only rely on the feeling

- Q: How is the lug butterfly valve connected to the flange?

- Lug type butterfly valve is also called a single flange type, that is, with a flange on the valve body, usually installed at the end of the pipe, and even the method is 1: double bolt lock on the valve body 2: into the flange 3: lock nut

- Q: Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- Different structure. The handwheel (or handle) of the D71X-10 is mounted directly on the valve stem, and the D371X-10 is operated by means of a bevel gear in combination with the worm, and the handwheel is mounted on the worm.

- Q: What do you mean by manual butterfly valve DN100 D341X-10?

- DN100 refers to the inside diameter of the butterfly valveD stands for butterfly valves3 represents the turbine drive4 represents the flange connectionThe 1 represents straight throughX is the representative of the Dengqen rubber seal10 represents the pressure of 1.0Mpa (10 kg)Butterfly valve (English: butterfly valve) refers to the closure of parts (valve or butterfly plate) for the disk, around the valve shaft to achieve rotation and closure of a valve, the main cut off on the pipe and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve is fully open to fully closed is usually less than 90 degrees, butterfly and butterfly stroke itself has no self-locking capability, in order to position the disc to install the valve stem on the worm gear. Using worm gear reducer, not only can the butterfly plate have self-locking ability, so that the butterfly board stops at any position, but also can improve the operation performance of the valve.

- Q: What are the butterfly valves models?

- Sealing surface material score:(1) soft sealing butterfly valve.1) the sealing pairs are made of non-metallic soft materials, which are made of non-metallic soft materials.2) the sealing pair is made of metal hard material and is made of non-metallic soft material.(2) metal hard sealing butterfly valve. The sealing pair is made of metal hard material and is made of metal hard material.According to the form of sealing:(1) forced sealing butterfly valve.1) elastic sealing butterfly valve. The pressure of the valve seat, seat, or plate is produced when the seal is closed by the pressure from the valve.2) additional torque seal butterfly valve. The seal is produced by a torque that is applied to the valve shaft.(2) pressure sealed butterfly valve. The pressure is greater than the pressure on the seat or plate.(3) automatic sealing butterfly valve. The pressure of the seal is automatically generated by the pressure of the medium.

- Q: What are the functions and uses of butterfly valves?

- Industrial butterfly valve features, capable of high temperature, applicable pressure range is higher, the valve nominal diameter is large, the valve made of carbon steel, the valve plate sealing ring using metal rings instead of rubber rings. Large high temperature butterfly valve welded by steel plate, mainly used for high temperature smoke duct and gas pipe.Construction: mainly composed of valve body, valve stem, disc and sealing ring. The valve body is cylindrical and has short axial length and is internally provided with a plate.

Send your message to us

Wafer Type Eccentric Butterfly Valve With PTFE Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 300 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords