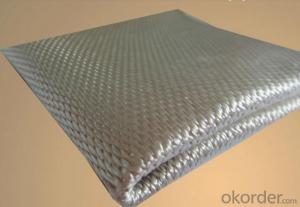

vermiculite coated fiberglass cloth high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

vermiculite coated fiberglass cloth

Well-distributed, even tensile strength, good vertical performance.

Fast impregnation, good moulding property, easily removing air bubbles.

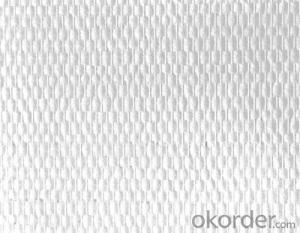

woven roving 800g /m2 non-alkali .

Products Introduction and Application

E-Glass woven roving is plain, biaxial fiberglass fabric that weaved with E-Glass direct roving. E-Glass Woven roving is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. It’s widely used in hand lay up, mold press, GRP forming process and robot processes to manufacture boats, vessels, plane, automobile parts, panels, storage tanks etc.

Products Features and Advantages

Well-distributed, even tensile strength, good vertical performance.

Fast impregnation, good moulding property, easily removing air bubbles.

High mechanical strength, less strength loss in wet condition.

Key Technical Data

Specs | Unit Mass (g/m2) | Breaking Strength≥N/2.5cm | Density | Weave | Roll Length (m) | Width (mm) | |||

Warp | Weft | Warp | Weft | ||||||

EWR400 | 400 | 1480 | 1380 | 3.5 | 3.3 | plain | 100-200 | 300-4000 | |

EWR600 | 600 | 1900 | 1800 | 3.0 | 2.5 | plain | 100-200 | 300-4000 | |

EWR800 | 800 | 2600 | 2350 | 2.0 | 2.0 | plain | 100-200 | 300-4000 | |

Packing Style

It is rolled on a paper core with a diameter of 100mm, then packed into a polyethylene bag, then outside packed into a separate cardboard box. Finally, the product can be ether shipped with cardboard box only or with pallet.

Storage

In dry and cool places. The best condition is with temperature between 15°C and 35°C, with a relative humidity between 30% -70%. Before use, please keep it in original package.

fibreglass Sample is free,freight is collect

- Q: How is fiberglass fabric used in the filtration industry?

- Fiberglass fabric is commonly used in the filtration industry due to its excellent filtration properties. It is used to manufacture filter bags, filter cartridges, and filter media for various applications such as air filtration, water filtration, and industrial filtration. The fabric's high strength and resistance to chemicals and temperature make it ideal for removing impurities, particles, and contaminants from fluids and gases. Additionally, its versatility allows for customization to meet specific filtration requirements, making it a valuable material in the filtration industry.

- Q: How is fiberglass fabric used in the automotive industry?

- Fiberglass fabric is commonly used in the automotive industry for reinforcing and strengthening various components. It is utilized in the manufacturing of car body panels, hoods, bumpers, and interior parts. The lightweight and durable nature of fiberglass fabric make it an ideal material for enhancing the structural integrity of vehicles without adding excessive weight. Additionally, fiberglass fabric can also be employed in the production of insulation materials, soundproofing panels, and upholstery, further improving the overall comfort and performance of automobiles.

- Q: Is fiberglass fabric resistant to chemicals in oil and gas industry?

- Yes, fiberglass fabric is generally resistant to chemicals in the oil and gas industry. It is known for its excellent chemical resistance properties, making it a suitable material for various applications in this industry.

- Q: Can fiberglass fabric be used for making flexible hoses?

- Yes, fiberglass fabric can be used for making flexible hoses. Fiberglass fabric is known for its high strength and flexibility, making it a suitable material for various applications, including the manufacturing of flexible hoses. The fabric can be woven into a flexible structure, allowing it to withstand bending, twisting, and stretching without losing its integrity. Additionally, fiberglass fabric is resistant to high temperatures, chemicals, and abrasion, making it ideal for use in hoses that transport fluids, gases, or even solids. Its durability and flexibility make it a popular choice in industries such as automotive, aerospace, and construction, where hoses are subjected to demanding conditions.

- Q: How is fiberglass fabric used in the production of thermal blankets?

- Fiberglass fabric is used in the production of thermal blankets due to its excellent insulating properties. The fabric is woven with fine fiberglass strands, which create a heat-resistant barrier. This helps to trap and retain heat, making the thermal blanket highly effective in providing warmth and insulation. The fiberglass fabric also adds durability and strength to the blanket, making it long-lasting and suitable for various applications.

- Q: What are the different dyeing options available for fiberglass fabric?

- Some of the different dyeing options available for fiberglass fabric include direct dyeing, acid dyeing, and disperse dyeing. Direct dyeing involves applying dye directly to the fabric, typically through a dye bath or by using a spray or brush. Acid dyeing involves using acid dyes that are specifically formulated for synthetic fibers like fiberglass. Disperse dyeing is another option, where disperse dyes are used to color the fabric through a process called heat transfer dyeing. These different dyeing options offer various methods to achieve desired colors and effects on fiberglass fabric.

- Q: Can fiberglass fabric be used in chemical-resistant applications?

- Indeed, chemical-resistant applications can utilize fiberglass fabric. Renowned for its exceptional resistance to a vast array of chemicals, fiberglass fabric proves to be an appropriate option for scenarios that entail exposure to diverse corrosive substances. Moreover, fiberglass fabric inherently withstands most acids, bases, solvents, and other chemicals, rendering it a favored material within chemical processing, petrochemicals, oil and gas, and wastewater treatment industries. Furthermore, fiberglass fabric exhibits the ability to endure high temperatures, augmenting its suitability for chemical-resistant applications entailing heat. In summary, fiberglass fabric's remarkable chemical resistance properties establish it as a reliable and long-lasting choice for a variety of chemical-resistant applications.

- Q: What is the cost range for fiberglass fabrics?

- The price range of fiberglass fabrics can differ based on a variety of factors, including the fabric's quality, weight, and width, as well as the supplier and any additional features or treatments applied to it. On average, fiberglass fabrics typically cost between $5 and $20 per yard. However, certain high-end or specialized fiberglass fabrics that possess specific properties or finishes can have higher price tags, sometimes exceeding $50 per yard or even more. It is important to remember that these prices are only approximate and may vary due to market conditions and individual suppliers. Furthermore, bulk orders or wholesale purchases might offer discounts, so it is advisable to directly contact suppliers for accurate pricing information.

- Q: How is fiberglass fabric bonded to other materials?

- Various methods and adhesives can be utilized to bond fiberglass fabric to other materials. One commonly employed technique is the use of epoxy resin, which guarantees a sturdy and long-lasting bond. The procedure entails applying a layer of epoxy resin onto the surface of the material to be bonded, and subsequently placing the fiberglass fabric on top of the resin. To ensure proper adhesion and eliminate any air bubbles, pressure is applied. The epoxy resin is then left to cure, typically for several hours or overnight, resulting in a robust bond between the fiberglass fabric and the material. Another approach involves the use of adhesive films or tapes specifically designed for bonding fiberglass fabric. These adhesive films usually require the application of heat to achieve the desired bonding. The process generally involves placing the adhesive film between the fiberglass fabric and the material to be bonded, and then applying heat through a heat gun or suitable equipment. As the adhesive film melts, it establishes a bond between the fiberglass fabric and the material. In certain cases, mechanical fasteners such as screws, rivets, or staples may be employed to secure the fiberglass fabric to other materials. This particular method is often chosen when a temporary or removable bond is desired, or when additional strength and stability are necessary. It should be emphasized that the choice of bonding method may vary depending on the intended application and the materials involved. It is advisable to consult with a professional or adhere to the manufacturer's guidelines to ensure proper bonding and achieve optimal results.

- Q: How is fiberglass fabric used in the fashion industry?

- The fashion industry has embraced fiberglass fabric as a versatile material that finds its place in various sectors. Avant-garde and futuristic designs are brought to life by utilizing fiberglass fabric's lightweight and durable qualities. Designers can experiment with unconventional shapes and structures, resulting in visually stunning and cutting-edge garments. The ability to mold and shape fiberglass fabric into different forms opens up endless possibilities for creating unique and innovative clothing pieces. Accessories in the fashion industry also benefit significantly from fiberglass fabric. Handbags, shoes, and other accessories can be reinforced with fiberglass, enhancing their strength and durability. Moreover, fiberglass fabric can be coated with metallic finishes or colorful dyes, elevating the aesthetic appeal of accessories and making them stand out. Fiberglass fabric has also found its place in the creation of protective clothing for specific purposes. Firefighters, for example, can benefit from garments that incorporate fiberglass fabric, providing them with an additional layer of heat and flame resistance. This application ensures the safety and protection of individuals in hazardous environments without compromising on comfort and style. However, it is important to note that fiberglass fabric does have limitations. Its stiffness and lack of breathability make it unsuitable for everyday clothing. Nonetheless, designers are constantly finding ways to incorporate fiberglass fabric into fashion pieces that are practical and wearable for special occasions or as statement pieces. In conclusion, fiberglass fabric plays a significant role in the fashion industry, allowing designers to push the boundaries of creativity and create unique, durable, and visually striking garments and accessories. While its usage may be limited to specific designs and applications, fiberglass fabric adds an element of innovation and sophistication to the world of fashion.

Send your message to us

vermiculite coated fiberglass cloth high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords