Three Ram BOP of High Quality with API 16A Standard

- Loading Port:

- Shanghai

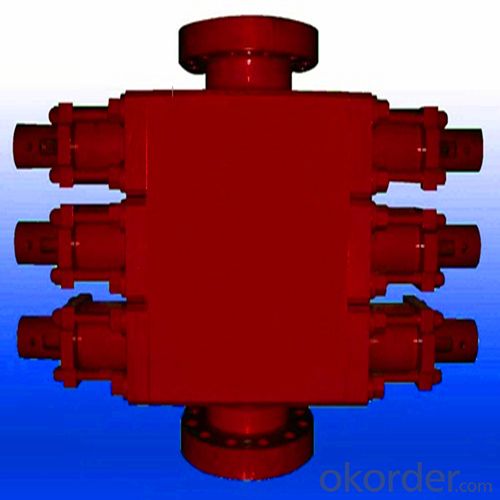

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Three Ram BOP Description

The ram preventer is designed and produced according to API 16A standard with different size of blind rams, pipe rams and shear rams. In order to saving time of replacement gate valve, variable ram designing put into use.

High-grade ram rubber core and side flange sealing can meet the extreme circumstances, such as high and low temperature or acidic conditions.

The housing of BOP is made of low alloy steel forgings or castings. Chemical composition, mechanical properties and forming process conform to the requirements of standards.

2. Main Features of Three Ram BOP

Ram preventers supplied by us are classified as two kinds of structure, Cameron and Shaffer type. The Cameron type preventer changes ram by hydraulic way, which is safe, reliable, and easy to replace the ram.

3. Three Ram BOP Images

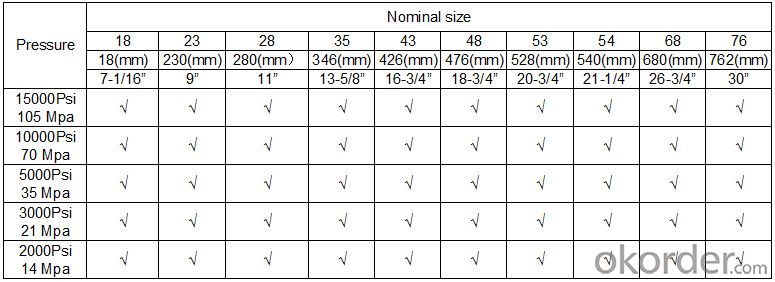

4. Three Ram BOP Specification

5. FAQ of Three Ram BOP

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I was just wondering if any body got there valve replaced,and if they are still having symptoms..Such as sweating,and shortness of breath.I do not know if i should see a cardologist, or the surgeon who replaced the valve.Any answers would be appreciated.Thank you.

- Why are you asking serious medical inquiries to idiots like me? it is your existence we are speaking about. in spite of if I had an aorta valve replace the dimensions of time MY discomfort lasted has basically to do with my actual problem, and has NO relevance to you. call YOUR physician N O W!!! it is her duty to charm to close what's threat-free for you, and what can be a symptom of massive aortic valve failure.

- Q: hi i have mitral valve prolapse/dysautonomia. when i get chest pains, its when i try to breathe. like i can take a little breath but if i take more my chest hurts. used to be pretty scary. i understand dysautonomia, but know know why it hurts to breathe in my heart sometimes. please help!

- Mitral valve prolapse is known to lead to chest pain, but the exact cause for the chest pain is not understood. The chest pain related to mitral valve prolapse is described as atypical, because it does not have the typical characteristics of other heart related pain. It is possible that your chest pain may or may not be related to your mitral valve prolapse. Chest pain that occurs or worsens with breathing is suggestive of a problem with the lining around the lungs (pleurisy.) A musculoskeletal cause like a pulled muscle is also possible. Anxiety would also be a possible cause. None of these conditions are serious. Chest pain resulting from MVP is not known to lead to any negative health consequences. Discuss it with your Cardiologist if you remain concerned.

- Q: I just got a new set of tired 2 months ago. The last 3 weeks I've had a separate tire go flat (3 in total). The last 3 the repair company said they were caused by cracked valve stems. So after the 3rd time it happened they replaced all valve stems on each tire. Now today I just got a 4th flat. That's 1 each week for the past 4 weeks. I'm taking into the shop this afternoon for them to inspect the tire. I suspect they will say it's again the valve stem. Any help on what I can do or what to say or ask to get them to fix the problem instead of just putting another bandaid on it? I'm very concerned about my safety and it really sucks that everytime i get into my car, I have to wonder, am i going to get a flat tire today...

- if you are running hub caps then maybe they are cutting into the valve stems. try running without hub caps and see if they crack.

- Q: My husband went to the doctor today, then called to say he won't be coming home because he has infective endocarditis. They sent him to another, larger, hospital in the region. Hours later he called and said that he needs surgery on the valve and they are moving him to another part of the country. I've been trying to read about it but I'm not sure I understand. What I've read says that they have to treat the infection with penicillin first, the he can have surgery. However, he's telling me he might have surgery when he get to the other hospital. He needs a new valve. Does this mean that his condition is worse than those I've read about or that they are simply doing things differently? Also, if you know. Does other illnesses make the risks much higher? He's got aspergillus in his lungs and have had 2/3 of the lungs removed. He has an immune deficiency (HIES) and he is physically weak from being sick. I know it's not good, but how bad is it?

- A leaky heart valve is a common cause of endocarditis, Endocarditis is a dangerous situation under any circumstance. The heart problem probably needs to be fixed to enable the endocarditis to clear up. The lung infection places him under added stress and increases the chances of something going wrong from the surgery, but he probably faces even higher risk in the long term if the endocarditis isn't brought under control. The surgery will only place a minor amount of additional stress on his body, and the valve replacement will probably make some almost instant improvements in his strength. Heart valve surgery can be usually be done with an endoscope that doesn't involve much trauma, so the surgical procedure itself is not a big risk.. I'm sure they would not be considering surgery at this point if it were not needed to help him recover.

- Q: if i put a power valve on my honda xlr 125 would it make my bike have faster acceleration

- Does not apply to 4 stroke motors.

- Q: Do blow off valves serve any purpose besides making the hiss when you shift? how much does one cost?

- Blow off valves are used on cars with a Turbo. They act like a safety valve when the pressure gets too high. That's the hiss you hear.

- Q: ok so the water main that comes into the basement the valve handle snapped off so how do i shut the water off so i can replace that valve? I called the water company and they said they cant shut off the supply to the house because it is private property and we have to call a plumber if so how can they shut the water off and on if we dont pay the bill?

- The water company should do it?? But a plumber can do it to

- Q: what to use to inflate self sealing tube with the presta valve?

- Gazoo If you do not have a pump that will accept a presta valve, then you can either buy a presta schrader pump, or a presta valve adapter. I have an adapter in each of my seat bags, they are only a buck or so, and will allow you to use service station air on your trips. Just cause you may not know, the presta valve has a rotating screw inside the valve. So to add or release air you must take your fingers and twist on that knurled circular end so that the presta valve extends away from the valve stem. Then when the tube is filled, twist it back tight to seal it off. Soccerref

- Q: I have recently been diagnosed with Endometriosis within the last 2 years. I have also had Mitral Valve Prolapse (MVP) for the past 10 years. ... Anyways... I was reading in a brochure for Endometrosis that there is a commonality between having those two diseases. If you know of the reasoning behind this I would be very interested in knowing. As I have yet to find an answer yet. I am just curious why having one will give you a larger likley hood to get the other. Thanks for your time and answers!

- I have been dianosed with Mitral Valve Prolapse for about 20 years now but do not have endometriosis. However, I read people who don’t have a heart anomaly (leaky valve) but have all the symptoms associated with MVP are said to be suffering from mitral valve prolapse syndrome (MVPS). Most people with MVPS that don’t have anything wrong with their heart, are said to have an imbalanced autonomic nervous system or dysautonomia. The autonomic nervous system manages most of our bodily systems, including the cardiovascular system; gastrointestinal and bowel functions; temperature regulation; reproduction; and the metabolic and endocrine systems so people with MVPS have an increased incidence of endometriosis.

- Q: In place of actual valve oil, can I use WD40? How about baby oil? Are there any household products which work?

- There are recipes for some home made oils on the internet, but most players and teachers will tell you to purchase some valve oil from the music shop. It's one of the cheapest musical instrument maintenance items available. WD40 and baby oil are NOT recommended.

Send your message to us

Three Ram BOP of High Quality with API 16A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords