Three-dimension HDPE compound plastic drainage Geonet Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 900000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

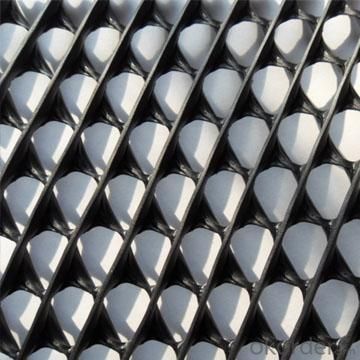

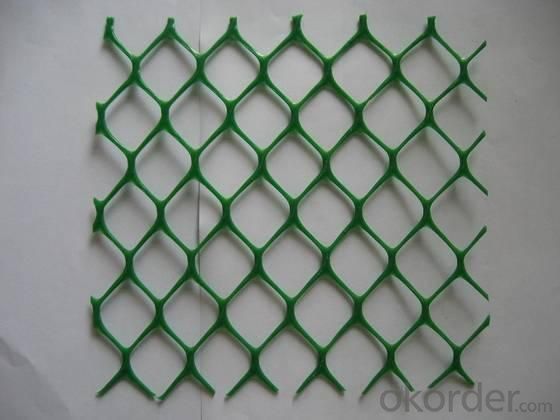

Tri-dimension composite genet for drainage is a new type of geosynthetics.

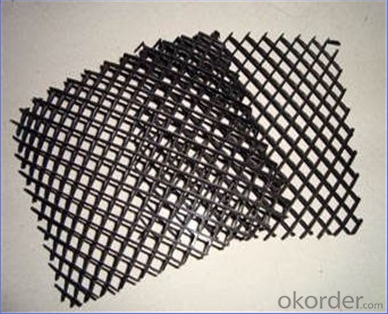

Its made of atri-dimension geonet coated with geotextile on both sides. Network core consists of a tri-dimension thick vertical rib, and a rip on top and bottom .

It can drain underground water quickly, also there is a protection system,which can block the capillary water under high load. At the same time, it can also reinforce and isolate of foundation.

Specifications:

core thickness: 5 mm - 8 mm;

Width: 2 - 4m,

composite geotextile:short fiber needle punched geotextile,filament spunbonded needle punched geotextile,the length at request.

Typical Application:

drainage in landfill; roadbed; railway,tunnel,underground structure,the retaining back wall, gardens and sports grounds.

Features:

Excellent drainage function, can bear long time hige press load

High tensile and shear strength

Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

Tri-dimension composite geonet for drainage can bear more than kpa compression load

Its anti-compression capacity is much larger than common geonet for drainage.

Specification :

Tri-dimension composite geonet for drainage

Drainage netwrok core | units | Specification | |||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 |

Thickness OV=20kpa | mm | 5.0 | 6.0 | 7.0 | 7.6 |

Hydraulic conductivity | m/s | K x 10 -4 | K x 10 -4 | K x 10 -3 | K x 10 -3 |

Elongation | % | <50< span=""> | <50< span=""> | <50< span=""> | <50< span=""> |

Tensile strength ( core network) | KN/m | 8 | 10 | 12 | 14 |

Geotextile | g/m2 | 200-200 | 200-200 | 200-200 | 200-200 |

Packaging & Delivery

| Packaging Details: | Standard export package or according to customers' requests Packing in Roll |

| Delivery Detail: | 10-20days after received deposit |

F&Q

How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can earthwork products be used in stormwater management systems?

- Yes, earthwork products can be used in stormwater management systems. Earthwork products such as geotextiles, geogrids, and erosion control mats can play a crucial role in controlling erosion, providing slope stabilization, and improving the overall performance of stormwater management systems. They help to prevent soil erosion, retain sediment, and enhance the filtration and drainage capabilities of stormwater facilities, ultimately reducing the impact of stormwater runoff on the environment.

- Q: Can geomembranes be used for pond liners?

- Yes, geomembranes can be used as pond liners. Geomembranes are impermeable synthetic materials that are designed to prevent water seepage. They are commonly used in various applications, including as liners for ponds and other water containment systems.

- Q: How do erosion control blankets help in preventing soil erosion?

- Erosion control blankets, also known as erosion control mats, play a crucial role in preventing soil erosion. These blankets are made of biodegradable materials like straw, coconut fiber, or jute, and are placed over the soil surface. They provide immediate protection by absorbing the impact of raindrops and reducing surface runoff. Additionally, erosion control blankets help to retain moisture, promote seed germination, and stabilize the soil by preventing wind and water erosion. The blanket's fibers interlock, creating a protective barrier that prevents soil particles from being washed away. Overall, erosion control blankets act as a temporary but effective solution to prevent soil erosion until vegetation establishes itself and provides long-term protection.

- Q: What are the key considerations when using geotextile bags for shoreline restoration?

- When using geotextile bags for shoreline restoration, some key considerations include the choice of geotextile material, the size and weight of the bags, proper installation techniques, the stability and durability of the bags, and the potential impact on the surrounding ecosystem. Additionally, factors such as wave action, water currents, and soil conditions should be taken into account to ensure effective and long-lasting shoreline restoration.

- Q: Can geotextile bags be used for erosion control?

- Yes, geotextile bags can be used for erosion control. These bags are commonly filled with soil or sand and placed in areas prone to erosion, such as riverbanks or shorelines, to stabilize the soil and prevent erosion by absorbing and dissipating the energy of moving water.

- Q: How are earthwork products different from regular construction materials?

- Earthwork products are different from regular construction materials because they are derived from natural sources such as soil, clay, and gravel, whereas regular construction materials are often manufactured or processed materials like concrete, steel, or bricks. Earthwork products are primarily used for shaping and modifying the terrain, such as grading, excavating, or filling, whereas regular construction materials are used for structural purposes, like building foundations, walls, or roofs.

- Q: What is the purpose of using geocells in highway shoulder stabilization projects?

- The purpose of using geocells in highway shoulder stabilization projects is to provide a cost-effective and efficient solution for reinforcing and stabilizing the soil and gravel materials used in shoulder construction. Geocells act as a confinement system, enhancing the load-bearing capacity of the shoulder and preventing lateral spreading of the materials. This helps to improve the overall stability, durability, and performance of the highway shoulder, reducing maintenance requirements and increasing its lifespan.

- Q: What are the different patterns available in earthwork products?

- There are several different patterns available in earthwork products, including but not limited to: herringbone, basket weave, running bond, circular, random, and modular. These patterns can be used to create various designs and textures in landscaping and construction projects.

- Q: Are there any specific earthwork products available for military engineering projects?

- Yes, there are specific earthwork products available for military engineering projects. These products include items such as geotextiles, geogrids, gabions, and blast mats, which are designed to enhance the performance and durability of military structures and offer protection against environmental and explosive forces. These earthwork products are often used in constructing roads, airfields, bunkers, and other military infrastructure.

- Q: What are the different design options available for earthwork products?

- Some of the different design options available for earthwork products include embankments, terraces, retaining walls, berms, and slope stabilization measures.

Send your message to us

Three-dimension HDPE compound plastic drainage Geonet Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 900000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords