Termite-repellent and Rodent-repellent Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Nylon jacket compound for non flame retardant optical fiber cable, communication cable and power cable with well performance of low temperature resistance and resistance to brittleness, substitute for imported No.12 nylon jacket compound.

2. Descriptionof Nylon compound:

This nylon jacket compound is developed by ourselves, in order to substitute for the PA12. It has a lot of advantages, such as processing easily, low temperature brittleness resistance, smooth surface, termite-repellent and rodent-repellent. It is suitable for jacket with low temperature brittleness resistance.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

Drying: be dried at 85-100°C for 3-6 hours before use.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature °C | 230 | 245 | 245 | 240 | 240 | 240 |

Note: The above temperature is recommended only, and the actual processing temperature should be according to the type of machine and environment.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA1012-A | PA1012-D |

Standard | Standard | ||

Density | g/cm3 | 1.1 | 1.1 |

Hardness | ≥Shore D | 60 | 60 |

Tensile Strength | ≥MPa | 50 | 50 |

Elongation at Break | ≥% | 180 | 180 |

Notched Impact Strength | ≥KJ/m2 | 30 | 30 |

Volume Resistivity | ≥% | 1.0×1012 | 1.0×1012 |

Dielectric strength | ≥MV/m | 24 | 24 |

Oxygen Index | — | — |

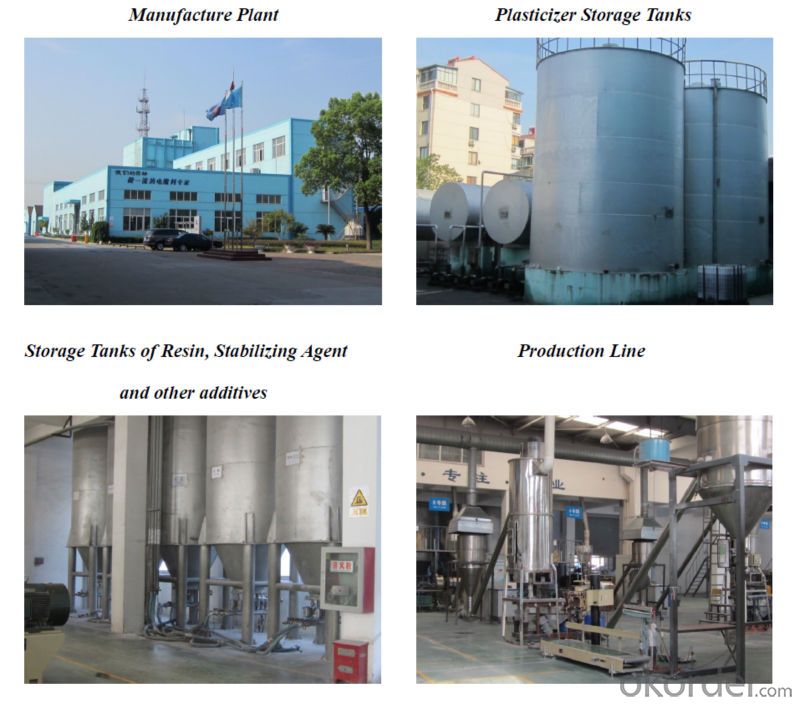

6. Company

- Q: What material is best for plastic gears?

- Gears can be made of PA, POM, etc., but PA and POM will have noise at high speeds.

- Q: I made of plastic raw materials accessories containing benzene, how to remove the teacher, please enlighten!

- Plastic generally does not contain benzene, ah, only polystyrene, ABS and other plastic molecular structure containing benzene ring, is a high polymer. Benzene is an organic solvent, low molecular substances, boiling point is low, very volatile.

- Q: How many types of plastics are there?

- PP: the name for polypropylene, five-star pin, handrails, floor mats and high strength is not necessary connections. Disadvantages: poor wear resistance and low surface hardness.

- Q: The difference between resin and plastics

- Resin material: it is natural, extracted from plants, the cost is higher. Plastic: it is chemical material, extracted from petroleum, Chen is lower

- Q: What is the hardness of PAEK+30%GF plastic material?

- Mohs hardness is mainly used in mineral classification. The Mohs scale from I to 10. the scratch resistance increasing (such as talc Mohs hardness is I, the diamond is 10), namely each scale corresponding to the Mohs material can be scraped traces in the previous stage of material. According to the Mohs hardness can determine the scratch resistance between contact with objects in the use of Engineering plastics.Engineering plastics Mohs hardness is between 2 and 3.

- Q: How many types of plastic materials are there?

- According to the different uses of plastics is divided into general and engineering plastics in general plastic refers to the yield, low price and wide application range of plastics, mainly including polyolefin, PVC, polystyrene, phenolic and aminoplastic five varieties. Many of the products used in everyday life are made from these general plastics. Engineering plastics are plastics that can be used as engineering structural materials and instead of metals to make machine parts and components. Such as polyamide, polycarbonate, POM, ABS resin, PTFE, polyester, polysulfone, polyimide and so on. Engineering plastics has the characteristics of low density, high chemical stability, good mechanical properties, excellent electrical insulation, easy processing, widely used in automobiles, electrical appliances, chemical industry, machinery, instruments, and other industries, is also used in space navigation, missiles, etc..

- Q: How to use all kinds of plastic materials?

- GPPS modified polystyrene 204The transparency of 88-92%, refractive index 1.59-1.60, suitable for light products, dyeing is strong, non-toxic and tasteless, no fungus growth, high impact strength, resistance to acid and alkali resistant performance is good, not on the basis of solvent, excellent electrical properties, easy molding, moisture less than 0.02% can maintain the strength and size of high humidity, but the brittleness.Suitable plastic products: decorations, lighting signs, lampshades, stationery, transparent toys, daily necessities, instrument lenses, freezers and thermal insulation in the refrigerator (after foaming).

- Q: What are the plastic bags made of?

- General civilian products, mostly polyethylene (PE) to do, PE is divided into low pressure high-density HDPE, low pressure high-density LDPE and linear low-density LLDPE

- Q: What is the material of plastic flat screen?

- It is made of hot spraying and cold fixing. It has the characteristics of wear resistance, corrosion resistance, toughness and so on. It can be used as a substitute for wire. The utility model has the advantages of corrosion resistance, light weight, long service life, no poison, no smell and good transparency.

- Q: What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- High density polyethylene (LDPE) transparency, the equivalent number can reach about 90%, but the temperature should be controlled well, there is no general problem, that is, the cost is higher than other products

Send your message to us

Termite-repellent and Rodent-repellent Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords