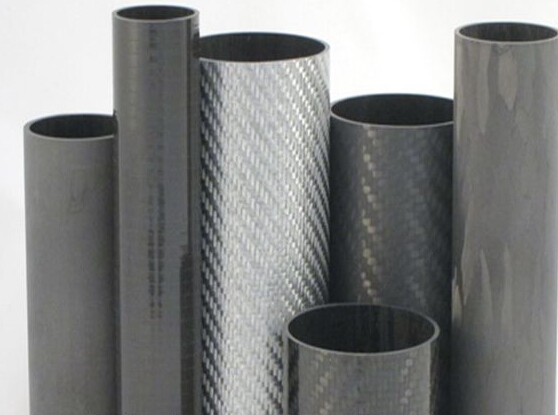

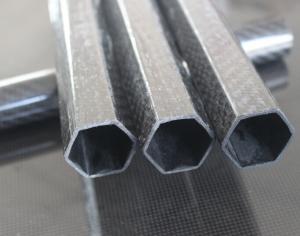

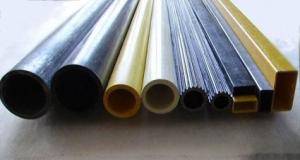

supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

3k China manufacturer carbon fiber tube

1.UV ressistance

2 non-magnetic elctromagnectic

3. enviromentally safe

Material Comparisons -

What are the benefits?

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

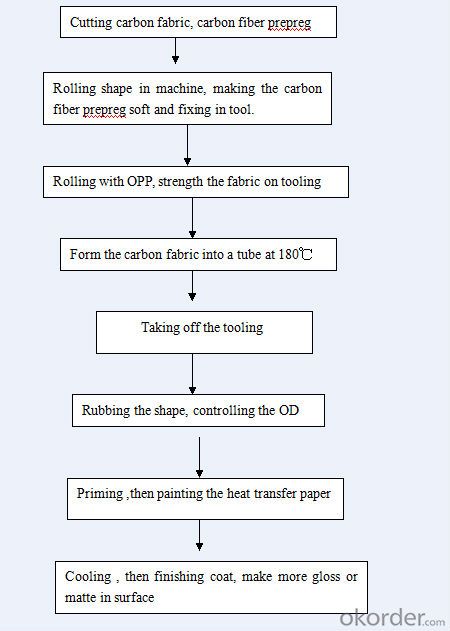

Manufacturing Process -

How are the tubes made?

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

Marine

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

photos:

We have established a considerable presence within the automotive industry supplying companies from mainstream car manufacturers to niche motorsport organisations.

We supply the majority of Formula 1 teams starting on the grid this season

We are at the forefront of composite innovation.

Experience handling and stocking very high tech materials.

Other automotive projects include:

Exhaust sleeves for both cars and motorcycles

Pit equipment

Suspension struts

Chassis members

- Q: The nozzle of a fire hose ejects water with a speed of 30.0 m/s. The stream of water is aimed 35 degrees above the horizontal ground. Assume the nozzle is at ground level, and each water drop is in free-fall.a. Find the speed of a water drop at the highest point of its motion.b. What is the magnitude of the acceleration of a water drop at the highest point of its motion?c. How far from the nozzle will the stream of water land?

- Take no Prisoners (Take no Sh*t) Rust in Peace Good Mourning/Black Friday Sweating Bullets In My Darkest Hour Peace Sells Tornado of Souls Holy Wars Rust in Peace Countdown Killing is my business Dave (I'm a rhythm guy, yes I know he plays solos too) BQ: Metallica BQ: Black Sabbath BQ: Hendrix

- Q: When i open my truck manually the alarm goes off and i have to put the key in the ignition for it to stop. I would like to know if there is someway to remove the alarm system or stop it from alarming whenever i open it manually

- Most hydraulics books should have a table.

- Q: I live in a house with an old Gaffers Sattler brand gas furnace/heater. Could this thing be releasing carbon monoxide? My house carbon monoxide detectors have never set off the alarm but perhaps the release from the furnace could be below its threshold. I would appreciate any advice on what situations might exist with the furnace that could produce carbon monoxide and what the solutions might be.

- Yeah, you can get many different types of locks. Locks that can be operated remotely by your cell phone, fingerprint sensitive door locks and many many more. The thing is that these systems will cost you thousands of dollars. I think feeding her cokes is far cheaper than the cost of locking family out. Seems to me like maybe you need to re-examine the family dynamics. Maybe you're going overboard. A cheaper solution might be to get a small fridge, one of those small 5 cubic foot fridges and keep it in your room. You can install a combination lock or a padlock and nobody can get in unless they have the key or know the combination. Otherwise you're going to be spending a TON of money just to protect your cokes. Hope this helps. '')

- Q: My fire alarms went off this afternoon and I'm not sure how to turn them off. Some are battery powered and some are hardwired into the house. I pressed the buttons on them, and I tried holding them in for a little while. Do I need to hold down the buttons longer and will this shut them all off at the same time? Thanks.

- Trust me. Leaving fire burning at night is not. Safe.

- Q: Hi,My myopia is pretty high. I wear powered goggles during swimming and I do just fine.I am thinking of taking up water polo for fun. I don't think I'll play it competitively. But I never seen a water polo player using goggles. Is there a rule against this?Just how violent is the sport of water polo? Any useful information

- Some fire alarms are linked check other alarms for smoke near them. Also they will chirp if batery is going bad but not go off for several seconds. Paint steam or fog can also set them off. I too would be woried sometimes they catch something not dangerous and sometimes its smoke you don't see.

- Q: What's the meaning of the plumbing PVC pipe joint specification "1/2" "X12" and "1/2" "x18"?

- Plumbing PVC pipe joint specifications 1/2, "X12" and "1/2" "x18" these two specifications belong to the British unit.

- Q: Ok im 12 and my parents are obssesed about safety is there cheap pads (under $60 for set) that can protect you? i dont want to look stupid when playing

- I would set up some large speakers and an amp and I would then proceed to serenade them with enchanting songs from my mother Land, long into the night.

- Q: Man, can you send me some national standards? Mainly for hydraulic use

- Here you are, some European companies, but you need to download them on the Baidu Library

- Q: Groundhog fire alarm Rottweiler and a husky

- are you building a home made cannon of some kind? i suggested it to someone recently and told them to make sure they got pressure rated pvc. the fittings cost more than the pipes, especially if you're only getting a metre or two of piping. well, the joiners are only 3 or 4 bucks, but the end piece and screw cap can be 15 or so. don't forget the primer when you're getting the adhesive. i got pressure rated pvc and all the fittings from bunnings, but that was a while ago, and i think i had to shop around a bit to get the right sizes and stuff. so, are you a diy plumber or a budding spudzooka builder? orange cannon?

- Q: Poll: Have you ever worn a pair of safety goggles and laughed when you looked at yourself in a mirror?

- false, i never had to put out a fire :)

Send your message to us

supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords