Supply 4x8 430 Stainless Steel Sheet in Wuxi

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

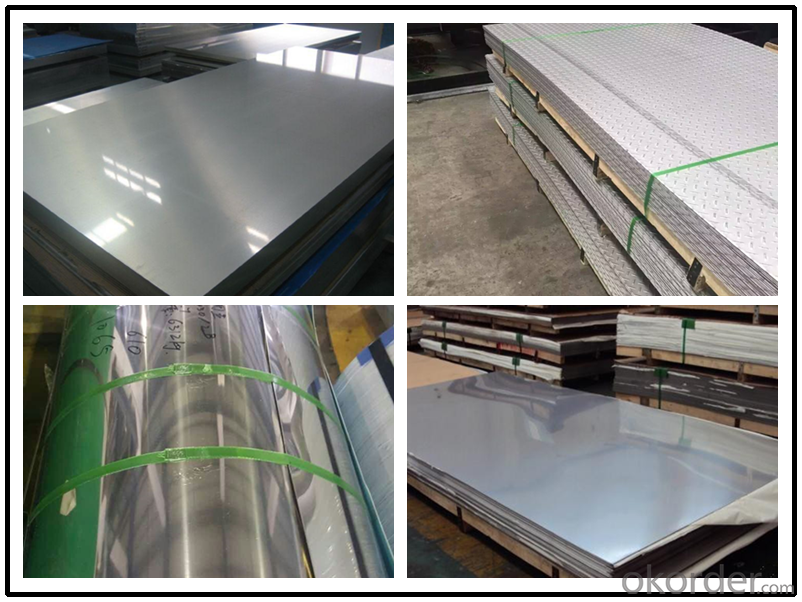

Details of 316L stainless steel sheet

Item | 316l stainless steel sheet |

Standard | AISI |

Material | 316l |

Surface | 2B,BA,NO.1,NO.4,NO.8,8K,hair line etc. |

Thickness | 0.4~100mm |

Width | 1000mm,1219mm,1500mm,1800mm,2000mm,2500mm,3000mm etc. |

Length | 1000,2000mm,2440mm,3000mm,5800mm,6000mm etc. |

Package | anti-water paper wrapped,iron strip fastened,put on wooden pallet,or as required |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

Price term | FOB,CFR,CIF,etc |

Payment term | TT,L/C |

Certificate | We accept the third inspections--SGS-BV etc. |

Chemical Composition

Specifications of Stainless Steel Sheets | |

Grade | 300 series |

| Standard | JIS,AISI,ASTM,GB,DIN,BS |

| Color | Primary |

| Certificate | ISO,SGS,ROHS |

| Thickness | 0.4mm~6mm |

| Width | 1000mm,1219mm,1500mm |

| Length | 1000mm~5000mm or as requirement |

| Application | building decoration , public facilities,anti-corrosion,etc. |

| Surface | NO.1,2B,No.8,No.4,BA,8K,HL |

| Technique | cold rolled & hot rolled |

| Packaging Details | Export sea worthy package + water proof paper + wooden palletin |

| Delivery Detail | In 3--7 working days |

| Surface | Characteristics |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses |

| BA | Cold rolled,bright annealed and skin-passed,the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

| NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarsestria,but thinner than No3,are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| NO.1 | The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks,mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

Packaging & Shipping

Application

- Q: Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets are commonly used in hygienic environments due to their inherent properties such as resistance to corrosion, ease of cleaning, and ability to withstand high temperatures. These sheets are frequently used in various industries, including healthcare, food processing, and pharmaceuticals, to ensure a clean and sterile environment.

- Q: What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q: What does stainless steel sheet S2 stand for?

- It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

- Q: Are stainless steel sheets suitable for power plant equipment?

- Yes, stainless steel sheets are suitable for power plant equipment. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it a popular choice for various industries, including power plants. Power plants often have harsh environments with high temperatures, pressure, and corrosive elements, and stainless steel can withstand these conditions effectively. It also has good heat resistance and can maintain its structural integrity at elevated temperatures, which is crucial for power plant equipment. Additionally, stainless steel sheets can be easily fabricated and welded to meet specific design requirements for power plant equipment, making them a versatile and reliable choice.

- Q: Can stainless steel sheets be etched or engraved?

- Indeed, it is possible to etch or engrave stainless steel sheets. Etching and engraving serve as widely employed techniques for crafting designs, patterns, and text onto stainless steel surfaces. These methodologies entail the elimination of a fine layer of the metal to form the desired design. Etching may be accomplished through the utilization of chemicals or the use of a laser, while engraving is commonly executed with a mechanical tool or laser. This process of etching or engraving can yield intricate and elaborate designs on stainless steel sheets, rendering them suitable for a broad array of applications, including signage, decorative panels, nameplates, and more.

- Q: Can stainless steel sheets be used for water purification systems?

- Yes, stainless steel sheets can be used for water purification systems. Stainless steel is a popular material choice for water purification systems due to its corrosion resistance, durability, and hygienic properties. It is highly resistant to rust and can withstand harsh environmental conditions, making it suitable for long-term use in water treatment applications. Additionally, stainless steel is non-reactive and does not leach harmful substances into the water, ensuring the purity and safety of the treated water. The smooth and non-porous surface of stainless steel also makes it easy to clean and maintain, minimizing the risk of bacterial growth and contamination. Overall, stainless steel sheets are an excellent choice for constructing various components of water purification systems, including tanks, filters, and pipes.

- Q: How do I remove stains or marks from stainless steel sheets?

- To remove stains or marks from stainless steel sheets, you can start by using a soft cloth or sponge with a mild soapy solution or dish detergent mixed with warm water. Gently scrub the affected area in the direction of the grain, rinsing with clean water afterward. For tougher stains, you can try using a non-abrasive cleaner specifically designed for stainless steel. Avoid using harsh chemicals or abrasive materials that can scratch the surface.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, certain measures can be taken. First, ensuring proper cleaning and maintenance is crucial. Regularly cleaning the stainless steel sheets with mild detergent and water, followed by thorough rinsing and drying, helps remove any contaminants that can lead to corrosion. Additionally, avoiding exposure to corrosive substances like chloride-based cleaners or harsh chemicals is important. Applying a protective coating or passivating the stainless steel surface can also provide an extra barrier against corrosion. Passivation involves treating the stainless steel with a mild oxidizing agent to promote the formation of a passive oxide layer, which enhances the metal's resistance to corrosion. Proper design and installation practices are equally vital. Avoiding the use of dissimilar metals in contact with stainless steel sheets and ensuring proper sealing and gasketing in joints or crevices can prevent crevice corrosion. Adequate ventilation and avoiding stagnant conditions can also help minimize corrosion risks. Regular inspection and maintenance are necessary to identify and address any signs of corrosion promptly. This includes checking for signs of pitting or crevices, addressing any damage or scratches, and promptly repairing or replacing any corroded areas.

- Q: What is the maximum length of a stainless steel sheet?

- The maximum length of a stainless steel sheet can vary depending on the manufacturer and specific requirements, but it is generally available in standard sizes of up to 12 feet (3.6 meters) long. However, longer custom lengths may be available upon request.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

Send your message to us

Supply 4x8 430 Stainless Steel Sheet in Wuxi

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords