Structural Steel Square Bars S30C Carbon Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structural Steel Square Bars S30C Carbon Steel Specification 1, Size: 120*120mm; 130*130mm; 150*150mm; 160*160mm; 200*200mm 2, Length: Max 12m 3, Heat Treatment: Normalizing, Annealing, Tempering, Quenching 4, Surface Treatment: Black, Polished, Galvanized Application 1, Used in mending drawing parts of panel die of automotive sheet metal & stamping die of large metal sheet. 2, Used in making hard surface. 3, Used as base plate of cold mold. 4, Used as fixed plate of drill jig. Chemical Composition % Products Show C Si Mn P S Cr Ni Cu 0.27-0.34 0.17-0.37 0.50-0.80 ≤0.035 ≤0.035 ≤0.25 ≤0.30 ≤0.25

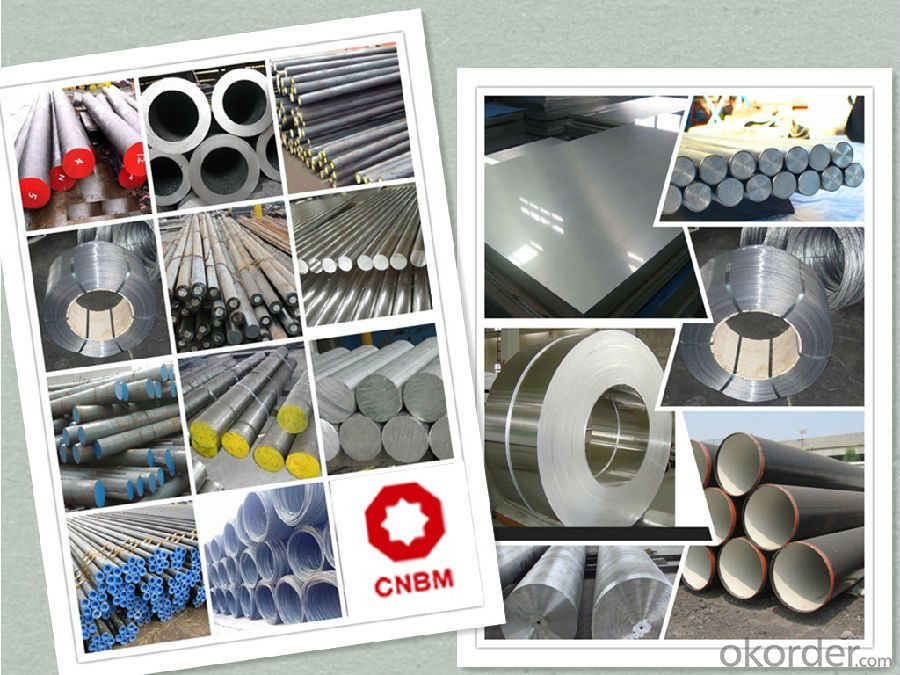

Work Shop

About Us

- Q: Can a steel square be used for fence-building projects?

- Yes, a steel square can be used for fence-building projects. Steel squares are versatile tools that can assist in ensuring accurate angles and measurements during the construction and installation of fences. They can help in marking out precise right angles, checking for levelness and plumbness, and ensuring the correct alignment of posts and rails, making them a valuable tool for fence builders.

- Q: How do you use a steel square to determine the angle of a compound taper cut?

- To determine the angle of a compound taper cut using a steel square, you need to follow a few steps. First, place the steel square's long side against the edge of the material you want to cut. Next, align the square's short side with the desired direction of the taper cut. Then, measure the distance from the square's short side to the material's edge at both ends of the cut. Finally, calculate the difference between the two measurements and use a tangent table or calculator to find the corresponding angle.

- Q: How do you use a steel square to create cove cuts?

- To use a steel square to create cove cuts, you will first need to set up your workpiece and gather the necessary tools. Cove cuts are commonly made on a table saw, so ensure that you have a suitable blade for the task. 1. Begin by marking the desired cove profile on the edge of your workpiece. Use a pencil or a marking knife to create a clear and precise line. 2. Next, position the steel square on the table saw, aligning one edge of the square with the blade. The square should be perpendicular to the blade and parallel to the miter gauge slots. 3. Adjust the blade height to the desired depth of the cove cut. It's recommended to start with a shallow cut and gradually increase the depth if needed. 4. Hold your workpiece firmly against the steel square, ensuring that the marked cove line is aligned with the blade. Use clamps or a push stick to maintain a safe distance from the blade while guiding the workpiece. 5. Turn on the table saw and slowly push the workpiece through the blade, following the cove line. Take your time and maintain a steady pace for a smooth and accurate cut. 6. Once the initial cove cut is complete, you may need to make additional passes to achieve the desired depth and smoothness. Simply adjust the blade height accordingly and repeat the process. 7. After completing the cove cuts, carefully inspect the workpiece to ensure the desired shape and quality. Sand or file any rough edges, if necessary, to achieve a finished look. Remember to prioritize safety while using power tools. Wear appropriate protective gear, such as safety glasses and hearing protection, and follow the manufacturer's instructions for your specific table saw model.

- Q: How do you use a steel square to mark a line parallel to a board edge at a specific distance?

- To achieve a line parallel to a board edge at a specific distance, you can follow these instructions: 1. Determine the desired distance for the parallel line. For instance, if you want the line to be 2 inches away from the board edge, take note of this measurement. 2. Align one side of the steel square parallel to the board edge, ensuring that it is flush against the board without any tilting or skewing. 3. Once the square is properly aligned, use a pencil or marking tool to make a reference point on the board along the square's edge. 4. Proceed to move the steel square along the board edge while maintaining the parallel alignment. Be consistent in keeping the same distance between the square's edge and the reference mark you made earlier. For example, if the desired distance is 2 inches, always ensure the square's edge is 2 inches away from the reference mark. 5. While moving the steel square, continue marking reference points at regular intervals. These points will serve as a guide for drawing a straight line later on. 6. Once you have marked enough reference points along the board edge, connect them using your pencil or marking tool to create a straight line. This line will remain parallel to the board edge with the specified distance maintained throughout its length. By utilizing a steel square and following these steps, you can accurately mark a line parallel to a board edge at a specific distance. This technique is commonly employed in woodworking, carpentry, and related trades to ensure precise measurements and markings.

- Q: Can a steel square be used for checking the squareness of workbenches?

- Yes, a steel square can be used for checking the squareness of workbenches. A steel square is a reliable tool for measuring right angles and ensuring that the corners of the workbench are perfectly perpendicular.

- Q: How do you use a steel square for measuring roof pitch?

- To use a steel square for measuring roof pitch, follow these steps: 1. Familiarize yourself with the steel square: A steel square, also known as a framing square, is a versatile tool with a long body and a shorter tongue perpendicular to it. The body usually measures 24 inches, while the tongue is about 16 inches. The square has various markings and angles that can help you measure and cut accurately. 2. Determine the pitch desired: The pitch of a roof refers to its slope or steepness. It is usually measured in terms of rise over run, where the rise is the vertical distance and the run is the horizontal distance. For example, a 4:12 pitch means that for every 12 inches of horizontal distance, the roof rises 4 inches. 3. Align the square: Hold the steel square with the body against the roof rafters or trusses, ensuring it is parallel to the eaves. The eaves are the lower edges of the roof that overhang the walls. Align the square so that the tongue points upwards towards the peak of the roof. 4. Measure the pitch: Look for the pitch scale on the body of the steel square. This scale is usually located on the outside edge and consists of a series of numbers representing pitch ratios. Place the square on the roof, aligning the edge with the eaves. Read the pitch ratio where the tongue intersects the scale. This will give you the roof pitch measurement. 5. Interpret the measurements: The pitch ratio you obtain will indicate the steepness of the roof. For example, a 6:12 pitch means the roof rises 6 inches for every 12 inches of horizontal distance. Using a steel square for measuring roof pitch is a simple and effective method. It allows you to accurately determine the slope of the roof, which is essential for various roofing tasks such as installing shingles, cutting rafters, or estimating materials needed for repairs or replacements.

- Q: Can a steel square be used for checking the squareness of a hand saw blade?

- No, a steel square cannot be used for checking the squareness of a hand saw blade. While a steel square is a useful tool for measuring right angles and ensuring squareness in various woodworking tasks, it is not specifically designed for checking the squareness of a saw blade. To accurately check the squareness of a hand saw blade, it is recommended to use a specialized tool called a saw set or a combination square. These tools are specifically designed to assess the squareness of saw blades and ensure precise and accurate cuts. Using a steel square for this purpose may not provide accurate results, as it may not align properly with the saw blade or provide the necessary measurements for assessing squareness. Therefore, it is important to rely on the appropriate tools to ensure the squareness of a hand saw blade.

- Q: Can a steel square be used for checking the flatness of a countertop joint?

- No, a steel square cannot be used for checking the flatness of a countertop joint. A steel square is a right-angle measuring tool primarily used for marking and checking squareness. It is not designed to accurately measure the flatness or levelness of a surface. To check the flatness of a countertop joint, a straightedge or a precision level would be more appropriate tools.

- Q: How do you use a steel square to find the center of an irregular shape?

- To use a steel square to find the center of an irregular shape, you can start by placing the steel square on the shape and aligning one of its edges with a prominent feature or side of the shape. Then, draw a line along the other edge of the square, extending it beyond the shape. Repeat this process by aligning the steel square with another side or feature of the shape and drawing another line. The point where these lines intersect is the approximate center of the irregular shape.

- Q: Can a steel square be used for checking the squareness of a workbench leg?

- A workbench leg's squareness can be checked using a steel square, a versatile tool commonly employed in woodworking and construction to guarantee precise right angles and squareness. To examine the squareness of a workbench leg, one can position the steel square against both the leg and the surface it should be perpendicular to. By aligning the square with the leg and verifying the perfect perpendicularity of the edges, one can ascertain whether the leg is square or requires adjustments. The steel square offers a dependable and accurate means of measuring squareness in different scenarios, such as with workbench legs.

Send your message to us

Structural Steel Square Bars S30C Carbon Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords