Carbon Structural Steel Square Bars S20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars S20C Specification 1, Size: 120*120mm; 130*130mm; 150*150mm; 160*160mm; 200*200mm 2, Length: Max 12m 3, Heat Treatment: Normalizing, Annealing, Tempering, Quenching 4, Surface Treatment: Black, Polished, Galvanized Application 1, Used in the manufacturing mechanical parts with high toughness but can not suffer great stress 2, Used in manufacturing carburizing and carbonitriding parts with high surface hardness. Chemical Composition % Products Show C Si Mn P S Cr Ni Cu 0.08-0.23 0.15-0.35 0.30-0.60 ≤0.030 ≤0.035 ≤0.20 ≤0.25 ≤0.25

Work Shop

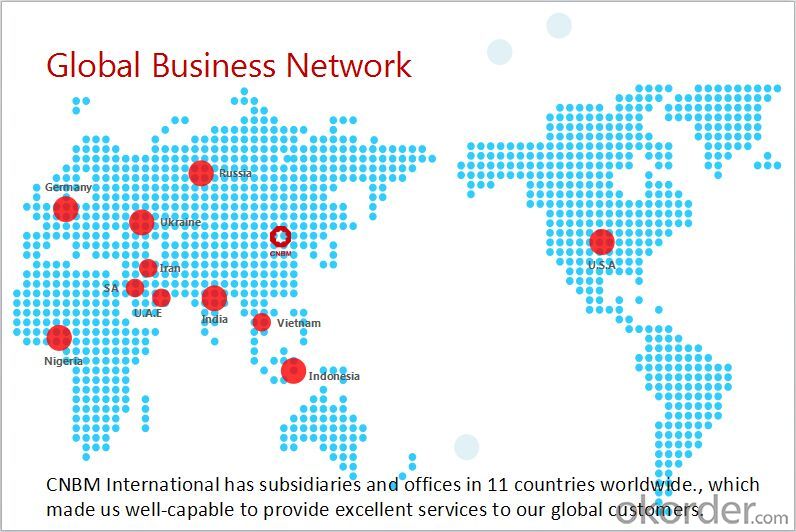

About Us

- Q: How do you use a steel square to transfer measurements?

- To transfer measurements using a steel square, one must first align the blade, which is one edge of the square, with the desired reference point on the object being measured. This reference point could be the edge of a board or the corner of a wall, for instance. Once the blade is properly aligned, the square should be firmly held in place while using a pencil or scribe to mark the measurement on the surface. The other edge of the steel square, called the tongue, can then be utilized to measure and transfer the marked measurement onto another surface. In order to transfer the measurement accurately, the tongue should be positioned against the edge of the surface where the mark is desired, ensuring alignment with the reference point. Subsequently, the square should be slid along the surface while maintaining alignment between the tongue and the reference point. This procedure guarantees precise transfer of the measurement. This process can be repeated as many times as necessary to transfer measurements onto various surfaces or objects. It is crucial to maintain alignment between the square and the reference point throughout the entire process to prevent any inaccuracies. In summary, using a steel square to transfer measurements involves aligning the square with a reference point, marking the measurement on one surface, and then utilizing the square's tongue to transfer that measurement onto other surfaces by aligning it with the reference point on each surface.

- Q: How do you use a steel square for stair layout?

- To use a steel square for stair layout, you would start by determining the desired rise and run measurements for the stairs. Then, using the steel square, you can mark the appropriate angles and dimensions on the stringers or skirt boards. The square's long arm is used to mark the rise or vertical measurement, while the shorter arm is used to mark the run or horizontal measurement. By aligning the square's edges with the stringers, you can accurately transfer the layout lines and ensure the stairs are built correctly.

- Q: How do you use a steel square to determine the length of a handrail?

- To determine the length of a handrail using a steel square, follow these steps: 1. Start by checking that the steel square is clean and clear of any debris or rust that could impact the accuracy of your measurements. 2. Place the steel square against one end of the handrail, ensuring it is flush with the end. 3. Move the steel square along the handrail's length until it reaches the other end, making sure it remains flush against the handrail throughout. 4. Once the square is aligned with the handrail's other end, take note of the measurement shown on the square. This measurement represents the handrail's length. 5. Remember that steel squares usually have measurements on both the inside and outside edges. Be sure to refer to the appropriate measurement line based on your specific requirements. 6. If you are dealing with a handrail that has multiple sections or curves, repeat the above steps for each section. For curved handrails, additional measurements along the curve may be necessary to ensure accuracy. Using a steel square to determine the length of a handrail is a straightforward and efficient method, providing precise measurements for construction or renovation projects.

- Q: Can a steel square be used for determining the correct depth of a dado cut?

- Yes, a steel square can be used for determining the correct depth of a dado cut. A steel square is a versatile tool that is commonly used in woodworking and carpentry. It has a right angle shape with a ruler along one of its sides, making it ideal for measuring and marking precise angles and distances. To use a steel square for determining the correct depth of a dado cut, you can follow these steps: 1. Measure the desired depth of the dado cut on the edge of the material using a ruler or tape measure. 2. Place the steel square vertically against the surface of the material, aligning the ruler with the measured depth mark. 3. Hold the steel square firmly in place, ensuring it is perpendicular to the material's surface. 4. Use a pencil or a marking knife to trace along the edge of the steel square, creating a visible line that represents the correct depth of the dado cut. By using a steel square, you can ensure that the depth of your dado cut is accurate and consistent. It provides a reliable and straightforward method for achieving precise measurements in woodworking projects.

- Q: How do you use a steel square to measure the width of a window frame?

- Here is an alternative version: To measure the width of a window frame using a steel square, follow these instructions: 1. Begin by selecting a steel square of an appropriate size. One side of the square should be longer than the width of the window frame you wish to measure. 2. Position the steel square against one side of the window frame, making sure it is aligned with the edge. 3. Obtain a measurement by aligning the end of the square with the opposite side of the window frame. Read the measurement at the point where the other side of the square intersects with the frame. 4. For accuracy, repeat this process on the other side of the window frame and compare the two measurements. The width of the window frame can be determined by averaging these two measurements. 5. If necessary, you can also measure the diagonal of the window frame by placing the steel square diagonally across the frame and following the aforementioned steps. This will help ensure that the frame is perfectly square. Always remember to note the units used for measurement, such as inches or centimeters, in order to effectively communicate the width of the window frame.

- Q: Can a steel square be used for checking the straightness of a board?

- Yes, a steel square can be used for checking the straightness of a board. A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly used in woodworking and carpentry. It consists of a long arm and a shorter arm set at a 90-degree angle. The long arm can be used to check the straightness of a board by aligning it along the edge of the board and observing if the board is perfectly straight or if there are any gaps or deviations. The right angle of the square can also be used to ensure that the edges of the board are square. However, it is important to note that while a steel square can provide a rough indication of the straightness of a board, it may not be as accurate as more specialized tools such as a straightedge or a level.

- Q: What are some common techniques for using a steel square in furniture repair?

- Some common techniques for using a steel square in furniture repair include measuring and marking accurate angles, checking for squareness and straightness, ensuring proper alignment during assembly, and verifying the levelness of surfaces.

- Q: What are some common mistakes to avoid when using a steel square for layout work?

- To ensure accurate and precise measurements when using a steel square for layout work, it is important to avoid the following common mistakes: 1. Verify accuracy: Prior to commencing any layout work, it is crucial to check the squareness and accuracy of your steel square. Ensure that the edges are straight and the angles are precisely 90 degrees. Using an imprecise square will lead to incorrect measurements and flawed layouts. 2. Pay attention to proper placement: Accurate measurements heavily rely on proper placement of the steel square. Make sure that the square is flush against the material you are working on and securely held in place. Any gaps or movement can result in skewed measurements and misaligned layouts. 3. Consider the thickness of the square: It is essential to take into account the thickness of the steel square when using it for layout work. Neglecting this factor can lead to inaccurate measurements, especially when marking or cutting along a specific line. 4. Recognize the importance of cleanliness: Maintaining the cleanliness of your steel square is vital for accurate measurements. Dirt, dust, or debris on the edges or surfaces of the square can affect its precision. Regularly clean your square and ensure it is free from any substances that may interfere with its accuracy. 5. Utilize correct marking techniques: Using the appropriate marking techniques is crucial when using a steel square for layout work. Employ a sharp pencil or marking knife to create clear and precise marks. Avoid using thick markers or pens that may create wider lines, which can result in measurement errors. 6. Avoid rushing through the process: Achieving accuracy and precision requires patience and attention to detail. Rushing through layout work with a steel square can lead to mistakes. Take the necessary time to ensure that each measurement and mark is executed correctly, and double-check when necessary. By avoiding these common mistakes, you can maximize the accuracy and precision of your layout work when utilizing a steel square.

- Q: How do you use a steel square to measure board widths at different angles?

- To use a steel square to measure board widths at different angles, first, place the square against the edge of the board. Then, align the desired angle on the square's blade with the edge of the board. Finally, read the measurement on the tongue of the square to determine the board width at that specific angle.

- Q: Can a steel square be used for roofing tasks?

- Indeed, roofing tasks can be accomplished using a steel square. Commonly referred to as a framing square or carpenter's square, this versatile tool finds its application in the realms of construction and roofing. Constructed primarily with steel, it boasts a surface adorned with an array of measurements and angles. Utilizing this tool proves advantageous for tasks such as mapping out and designating roof rafters, ascertaining angles and cuts, and guaranteeing precise measurements throughout the roofing procedure. Its robust and long-lasting construction renders it highly suitable for the rigorous demands entailed in roofing endeavors.

Send your message to us

Carbon Structural Steel Square Bars S20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords