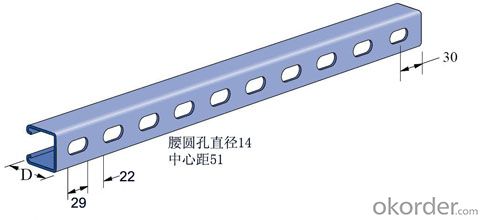

stress components -- type steel and fastener (with locking serrations)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The professional good coordination, improve indoor space elevation

Has good compatibility, the professional can share a hanger; make full use of space, can make each professional bundles can be good coordination.

- force, stable and reliable

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

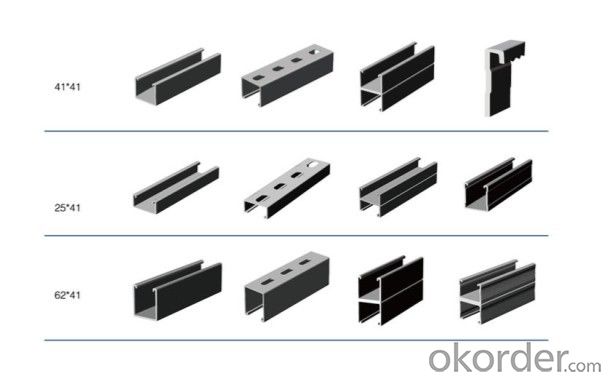

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

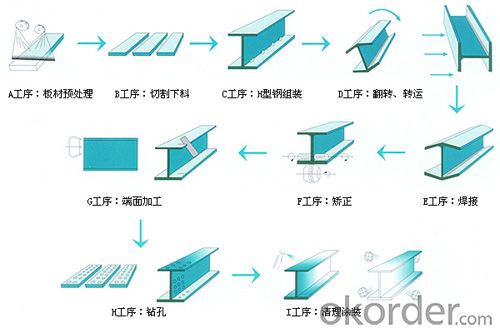

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room equipmentcontainer, mineral support etc.. The best-selling products, well received by customers. This is a company won the trust of customers, has broad prospects for development of theenterprise.

Z type steel main points: equilateral Z type steel, galvanized Z type steel, solar stent type Zsteel, the major and medium small type Z steel, Z shaped steel purlin, template supportoverlapped Z type steel Z steel, Z steel, such as automobile profiles, the above specifications for factory main products, such as shape, specifications, drawings can betransfer to my company.

- Q: What are the factors to consider when designing steel structures for educational institutions?

- When designing steel structures for educational institutions, several factors need to be considered to ensure a safe and functional environment for students, teachers, and staff. Some of the key factors include: 1. Structural Integrity: The structural integrity of the steel framework is of utmost importance. The structure must be able to withstand various loads, including the weight of the building, live loads from occupants, and potential seismic or wind loads. Proper analysis and design must be conducted to ensure the strength and stability of the structure. 2. Safety and Security: Educational institutions must prioritize the safety and security of their occupants. Steel structures should be designed to meet building codes and regulations for fire safety, emergency egress, and accessibility. Additionally, proper security measures should be incorporated, such as reinforced doors and windows, to protect against potential threats. 3. Flexibility and Adaptability: Educational institutions often require flexible spaces that can be easily adapted to changing needs. Steel structures offer the advantage of long spans, allowing for open and versatile layouts. Considerations should be made to accommodate future expansions, renovations, or changes in the educational curriculum. 4. Acoustics and Noise Control: Educational facilities require appropriate acoustic design to minimize noise transmission between classrooms, halls, and other spaces. Steel structures should incorporate sound insulation materials and techniques to create a conducive learning environment. 5. Energy Efficiency: Designing steel structures with energy-efficient features can help reduce long-term operational costs. Considerations should be made for insulation, natural lighting, energy-efficient HVAC systems, and renewable energy sources to promote sustainability and reduce environmental impact. 6. Aesthetics and Branding: Educational institutions often have unique architectural requirements to reflect their identity and branding. Steel structures can be designed to incorporate aesthetic elements, such as decorative facades, unique rooflines, or the use of colors and textures, to enhance the visual appeal of the campus. 7. Maintenance and Durability: Steel structures should be designed for ease of maintenance and long-term durability. Considerations should be made for the selection of corrosion-resistant materials, proper coatings, and structural detailing that allows for easy inspection and repair. 8. Cost and Time Efficiency: The cost and time required for construction should be considered during the design phase. Steel structures offer advantages in terms of faster construction compared to traditional materials, reducing project timelines and associated costs. By considering these factors, architects and engineers can design steel structures that are safe, functional, visually appealing, and conducive to learning in educational institutions.

- Q: How are steel structures used in public infrastructure projects?

- Steel structures are extensively used in public infrastructure projects due to their strength, durability, and versatility. They are commonly employed in the construction of bridges, stadiums, airports, and high-rise buildings, providing structural support and ensuring the safety and longevity of these critical structures. Steel's excellent load-bearing capacity allows for the construction of large-span structures, reducing the need for excessive columns or supports. Moreover, steel structures are often prefabricated off-site, allowing for faster construction and minimizing disruptions to the surrounding environment.

- Q: How are steel structures designed for resisting soil movements and settlements?

- Steel structures are designed to resist soil movements and settlements through various methods and techniques. One of the primary considerations in the design process is to ensure that the foundation of the steel structure is strong and stable enough to withstand the anticipated soil movements. Firstly, engineers analyze the soil conditions at the site to determine the type of foundation that would be most suitable. Factors such as soil type, bearing capacity, and potential settlement are taken into account to select the appropriate foundation system. Common foundation types for steel structures include shallow foundations, such as spread footings and mat foundations, as well as deep foundations, such as piles or drilled shafts. To mitigate the effects of soil movements and settlements, engineers can incorporate measures such as providing additional reinforcement in the foundation, using flexible joints or connections in the steel structure, and implementing ground improvement techniques. In terms of foundation reinforcement, engineers may add steel reinforcement bars or beams to increase the load-bearing capacity and resistance to settlement. This reinforcement helps distribute the loads evenly and prevents excessive settlement or differential movements that could compromise the stability of the structure. Flexible joints or connections are another way to accommodate soil movements. These connections allow for some flexibility and movement between structural elements, minimizing the impact of soil settlements. The use of expansion joints or sliding connections in steel structures allows for relative movement between different sections of the structure, reducing the risk of damage caused by soil movements. In some cases, ground improvement techniques may be employed to enhance the soil's properties and reduce settlement. Techniques such as soil stabilization, compaction, or the use of geosynthetics can improve the soil's strength, stability, and drainage characteristics. This, in turn, helps to minimize potential soil movements and settlements that could affect the steel structure. Overall, the design of steel structures for resisting soil movements and settlements requires a comprehensive understanding of the soil conditions, careful consideration of foundation design, and the incorporation of appropriate reinforcement and flexibility measures. By implementing these techniques, engineers can ensure that steel structures can safely and effectively resist the forces associated with soil movements and settlements.

- Q: What are the different types of steel coatings for protection against corrosion?

- There are several types of steel coatings available for protection against corrosion, including galvanized coatings, zinc-rich coatings, epoxy coatings, polyurethane coatings, and powder coatings. Each of these coatings offers unique properties and levels of corrosion resistance, making them suitable for different applications and environments.

- Q: Can steel structures be designed with bicycle parking facilities?

- Yes, steel structures can be designed to incorporate bicycle parking facilities. Steel is a versatile material that can be used to create various types of structures, including those that provide parking space for bicycles. These structures can be designed with features such as bike racks, secure enclosures, or even multi-level parking systems to accommodate different needs and capacities. Steel's strength, durability, and flexibility make it suitable for constructing customized, efficient, and long-lasting bicycle parking facilities.

- Q: How are steel structures designed to be resistant to corrosion?

- To achieve corrosion resistance, steel structures undergo a comprehensive approach that involves material selection, coating application, and maintenance. The first step is to carefully choose the appropriate steel grade. Stainless steel, for instance, contains a higher chromium content that forms a protective oxide layer on the surface, preventing corrosion. Additionally, galvanized steel is commonly utilized, with a layer of zinc acting as a sacrificial barrier against corrosion. Moreover, the application of proper coatings plays a crucial role in safeguarding steel structures. Epoxy and polyurethane coatings are frequently employed to create a physical barrier, shielding the steel from moisture and corrosive elements. These coatings are meticulously applied in multiple layers to ensure optimal protection. Regular maintenance is also imperative in guaranteeing the corrosion resistance of steel structures. This entails regularly inspecting for any signs of damage or deterioration in the coatings and promptly addressing them. Regular cleaning, involving the removal of accumulated dirt or debris, further aids in preventing corrosion by reducing moisture retention. In conclusion, steel structures are designed with corrosion resistance in mind, utilizing suitable steel grades, protective coatings, and regular maintenance. These measures collectively contribute to prolonging the lifespan of steel structures and preserving their structural integrity.

- Q: How are steel structures used in the construction of recreational facilities?

- Due to its many advantages, steel structures are widely utilized in the construction of recreational facilities. The exceptional strength and durability of steel make it an ideal material for building large and intricate structures, which is particularly important in recreational facilities that often require expansive areas and long spans with minimal support columns. Furthermore, steel structures offer design flexibility and can be easily tailored to meet specific requirements. This allows architects and designers to create one-of-a-kind and visually appealing recreational facilities, such as stadiums, sports arenas, and theme parks. In addition, steel is an environmentally friendly and sustainable material. It can be recycled indefinitely without losing its properties, reducing the need for new raw materials and minimizing waste. Consequently, steel structures are a more sustainable choice for constructing recreational facilities. Moreover, steel structures possess resistance to fire, corrosion, and pests, ensuring the safety and longevity of recreational facilities. This is especially crucial in areas prone to extreme weather conditions or in close proximity to bodies of water. Furthermore, steel structures provide cost-effective solutions for recreational facilities. The prefabrication and modular construction techniques associated with steel structures enable faster and more efficient construction, resulting in reduced labor and overall project costs. Additionally, steel structures require minimal maintenance, leading to long-term cost savings. Overall, steel structures play a critical role in the construction of recreational facilities by offering strength, durability, flexibility, sustainability, safety, and cost-effectiveness. As a result, they have become the favored choice for architects, designers, and developers in the recreation industry.

- Q: How are steel structures designed to minimize the risk of structural failure?

- To minimize the risk of structural failure, steel structures undergo a thorough design process that takes into account various key factors. Firstly, the forces that the structure will be exposed to, such as gravity, wind, seismic activity, and live loads, are carefully analyzed. This analysis helps determine the appropriate size and configuration of the steel members, ensuring they can safely withstand these forces without experiencing excessive stress or deformation. Secondly, redundancy is incorporated into the design of steel structures. This means including extra structural members or connections to create alternative load paths in case one component fails. By doing so, the overall safety and reliability of the structure are enhanced. Another important consideration in steel structure design is the potential failure modes. Engineers examine factors like buckling, fatigue, and brittle fracture to minimize the risk of these failure modes occurring. For instance, bracing and stiffeners may be added to prevent buckling, and fatigue-resistant details may be incorporated to withstand cyclic loading. Furthermore, proper connections and joints are crucial for ensuring structural integrity. The connections between steel members are meticulously designed and detailed to provide adequate strength and stiffness. They are also designed to accommodate any potential movement or deformations, preventing the failure of individual components and ensuring overall stability. Lastly, maintenance and inspections are taken into account during the design of steel structures. Regular inspections and maintenance routines are implemented to detect any signs of deterioration, such as corrosion or fatigue cracking, which could compromise the structural integrity. By promptly addressing these issues, the risk of structural failure can be minimized. In conclusion, the design of steel structures considers load analysis, redundancy, failure mode consideration, proper connections, and maintenance to ensure the safety and reliability of the structure, effectively reducing the risk of structural failure.

- Q: How are steel structures designed to resist impact and blast loads?

- Steel structures are designed to resist impact and blast loads through various measures. The design process includes selecting appropriate materials, employing structural redundancy, incorporating energy-absorbing mechanisms, and implementing blast-resistant design principles such as compartmentalization and venting. By combining these strategies, steel structures can effectively withstand and mitigate the effects of impact and blast loads, ensuring the safety and durability of the overall structure.

- Q: How are steel structures designed for residential buildings?

- Steel structures for residential buildings are typically designed by engineers who consider factors such as the architectural requirements, load-bearing capacity, and safety regulations. The design process involves analyzing the building's intended use, determining the required structural elements, and using computer-aided design software to create detailed plans. The design is then reviewed and approved by authorities before construction begins.

Send your message to us

stress components -- type steel and fastener (with locking serrations)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords