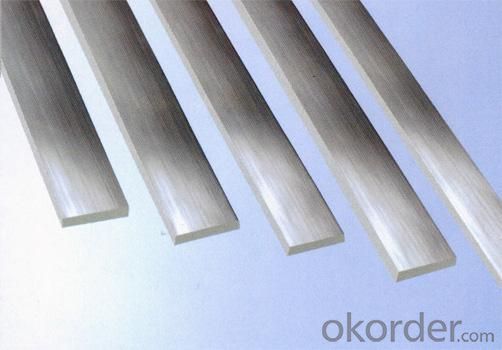

Steel flat bar steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel flat bar steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel flat bar steel flat bar for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel flat bar steel flat bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of city overpass steel structure

Project type: city overpass

Bridge height: 5M

Span: 60M

Design load: crowd 4.5KN/M2, one-side handrail 5.0 KN/m

Structure type: the main bridge is continuous girder bridge, with one stairway at both ends. The main bridge adopts three-span layout. Stairways are made of continuous steel girder structure.

1. GB standard material

2. High Structural safety and reliability

3. The production can reach GB/JIS/ISO/ASME standard

Packaging & Delivery of city overpass steel structure

1. According to the project design and the component size, usually the main component parts are nude packing and shipped by bulk vessel. And the small parts are packed in box or suitable packages and shipped by containers.

2. This will be communicated and negotiated with buyer according to the design.

Engineering Design Software of city overpass steel structure

Tekla Structure \ AUTO CAD \ PKPM software etc

⊙Complex spatial structure project detailed design

⊙Construct 3D-model and structure analysis. ensure the accuracy of the workshop drawings

⊙Steel structure detail ,project management, automatic Shop Drawing, BOM table automatic generation system.

⊙Control the whole structure design process, we can obtain higher efficiency and better results

Technical support of city overpass steel structure

Worker | Rate of frontline workers with certificate on duty reaches 100% |

Welder | 186 welders got AWS & ASME qualification 124 welders got JIS qualification 56 welders got DNV &BV qualification |

Technical inspector | 40 inspectors with UT 2 certificate 10 inspectors with RT 2 certificate 12 inspectors with MT 2 certificate 3 inspectors with UT3 certificate |

Engineer | 21 engineers with senior title 49 engineers with medium title 70 engineers with primary title. 61 First-Class Construction Engineers 182 Second-Class Construction Engineers |

International certification | 10 engineers with International Welding engineer, 8 engineers with CWI. |

Production Flow of steel structure/steel frame/steel construction

Material preparation—cutting—fitting up—welding—component correction—rust removal—paint coating—packing—to storage and transportation (each process has the relevant inspection)

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the key considerations in the design of steel structures for educational campuses?

- When designing steel structures for educational campuses, there are several key considerations that need to be taken into account. These considerations include the following: 1. Safety: One of the primary concerns in the design of any structure is safety. Steel structures must be designed to withstand various loads, including wind, snow, and seismic forces. The design should also consider fire safety measures, such as the inclusion of fire-resistant materials and proper egress routes. 2. Flexibility: Educational campuses often require flexible spaces that can be easily adapted to accommodate changing needs. Steel structures offer greater flexibility compared to other construction materials, as they can be easily modified and expanded without compromising their structural integrity. 3. Durability: Educational campuses typically have a long lifespan, so it is crucial to consider the durability of the steel structure. Steel is known for its strength and resistance to corrosion, making it an ideal material for long-lasting structures. The design should also consider factors such as maintenance requirements and the potential for future renovations or additions. 4. Functionality: The design of steel structures for educational campuses should prioritize functionality. This includes considering the layout and arrangement of spaces, ensuring proper ventilation and lighting, and providing adequate accessibility for students and staff with disabilities. 5. Aesthetics: While functionality is crucial, the design of steel structures should also consider the aesthetic appeal of the campus. Steel can be used to create visually stunning structures, and the design should take into account the overall architectural style and vision of the campus. 6. Sustainability: In today's environmentally conscious world, sustainability is an important consideration in the design of any structure. Steel is a recyclable material, and its use can contribute to the overall sustainability of the campus. The design should consider energy-efficient features, the use of sustainable materials, and the incorporation of renewable energy sources. 7. Cost-effectiveness: Finally, the design of steel structures for educational campuses should consider cost-effectiveness. While steel can be more expensive upfront compared to other materials, its durability and low maintenance requirements can result in long-term cost savings. The design should also consider construction timelines and potential cost overruns. In conclusion, the key considerations in the design of steel structures for educational campuses include safety, flexibility, durability, functionality, aesthetics, sustainability, and cost-effectiveness. By carefully considering these factors, designers can create steel structures that meet the unique needs of educational institutions while providing safe, functional, and visually appealing spaces for students and staff.

- Q: How are steel structures used in transportation infrastructure?

- Steel structures are widely used in transportation infrastructure for their strength, durability, and versatility. One of the key applications of steel structures in transportation is in the construction of bridges. Steel bridges offer exceptional load-bearing capacity, allowing them to span long distances and carry heavy loads. The high strength-to-weight ratio of steel makes it an ideal material for building bridges, as it enables the construction of lighter and more efficient structures. Steel is also commonly used in the construction of railway tracks and platforms. The tracks are typically made of steel rails that provide a smooth and durable surface for trains to travel on. Steel platforms provide a sturdy and long-lasting foundation for passengers to board and disembark from trains. In both cases, the use of steel ensures the integrity and safety of the transportation infrastructure. Furthermore, steel is utilized in the construction of various transportation facilities, such as airports and ports. Airports require large, open spaces, and steel structures provide the necessary structural support for hangars, terminals, and runways. Ports rely on steel structures for the construction of docks, piers, and wharves, which need to withstand the constant exposure to water, weather, and heavy loads. In addition to its strength and durability, steel also offers flexibility in design and construction. It can be easily fabricated into various shapes and sizes, allowing for the creation of intricate and aesthetically pleasing structures. Steel structures can be prefabricated off-site and assembled quickly, minimizing disruption to transportation operations. Overall, steel structures play a crucial role in transportation infrastructure by providing the necessary strength, durability, and versatility for the construction of bridges, railway tracks, platforms, airports, and ports. Their use ensures the safety, efficiency, and longevity of transportation systems, contributing to the development and connectivity of communities and economies.

- Q: What are the common fire protection measures for steel structures?

- Common fire protection measures for steel structures include the application of fire-resistant coatings or intumescent paint, the use of fireproofing materials such as gypsum or concrete, the installation of fire-resistant barriers or walls, and the implementation of fire suppression systems such as sprinklers or fire extinguishers. These measures aim to delay the onset of structural failure during a fire, allowing occupants to safely evacuate and minimizing property damage.

- Q: What are the considerations for designing steel structures for seismic zones?

- When designing steel structures for seismic zones, there are several important considerations to take into account. Firstly, it is crucial to analyze the seismic hazard of the specific location and understand the potential magnitude and frequency of earthquakes. This information helps determine the appropriate design criteria and level of seismic resistance required. Another consideration is the selection of suitable materials and construction techniques. Steel, being a ductile material, is often preferred for seismic-resistant structures as it can absorb and dissipate energy during earthquakes. The use of high-strength steel and proper welding techniques can enhance the structural integrity and resistance to seismic forces. Moreover, the structural design should incorporate seismic load calculations based on the local building codes and regulations. These codes provide guidelines for determining the design forces and detailing requirements to ensure the safety and performance of the structure during earthquakes. Special attention should be given to the design of connections, bracing systems, and the overall lateral load-resisting system. Additionally, detailing plays a crucial role in seismic design. Proper reinforcement and anchorage of structural components, such as beams, columns, and braces, are essential to prevent failure and ensure stability during seismic events. The detailing should consider potential modes of failure, such as shear, flexure, and torsion, and provide adequate strength and ductility to resist these forces. Lastly, regular inspections and maintenance of the steel structure are necessary to ensure its long-term performance in seismic zones. This includes monitoring for any signs of damage or deterioration, addressing any issues promptly, and implementing appropriate retrofitting measures if required. Overall, designing steel structures for seismic zones requires a comprehensive understanding of the seismic hazard, careful material selection, adherence to building codes and regulations, meticulous detailing, and ongoing maintenance to ensure the safety and resilience of the structure.

- Q: What are the different types of foundation systems used for steel structures?

- Steel structures can be supported by various foundation systems, each designed to ensure long-term durability and stability. Common types of foundation systems for steel structures include spread footings, strip footings, mat foundations, pile foundations, caisson foundations, and pier foundations. Spread footings involve wider footings that distribute the load over a larger area, making them suitable for smaller structures or areas with high soil bearing capacity. Strip footings, on the other hand, are narrow footings that support the load along a continuous strip. They are commonly used for larger structures or areas with lower soil bearing capacity. Mat foundations, also known as raft foundations, are thick slabs of reinforced concrete that distribute the load over a wide area. They are ideal for heavy or tall structures as they provide significant support and stability. Pile foundations involve driving long columns, called piles, deep into the ground to transfer the load to a more stable soil layer. They are used in areas with weak or unstable soil conditions. Caisson foundations are similar to pile foundations but are larger in diameter. They are constructed by drilling or excavating a cylindrical hole and filling it with concrete or reinforcing it with steel. Caisson foundations are commonly used for tall or heavy structures such as high-rise buildings or bridges. Pier foundations consist of multiple vertical columns or piers that support the load. They are often used in combination with other foundation systems to provide additional support and stability. The choice of foundation system depends on factors such as the size and weight of the structure, soil conditions, and budget. It is important to analyze the site conditions and consult with a structural engineer to determine the most suitable foundation system for a steel structure.

- Q: What are the different types of steel trusses used in steel structures?

- There are several types of steel trusses commonly used in steel structures, including the Warren truss, Pratt truss, Howe truss, and K truss. Each type has its unique design and configuration, allowing for different load-bearing capacities and structural requirements.

- Q: Does the steel structure belong to high-risk industries?

- Involving high-risk chemicals (Public Security Bureau), fire control, occupational health, major hazard sources, environmental protection procedures should be handled accordingly, there are three simultaneous reports.

- Q: What are the fire resistance ratings of steel structures?

- The fire resistance ratings of steel structures can vary depending on various factors such as the type of steel used, the design of the structure, and the fire protection measures implemented. However, steel structures generally have excellent fire resistance capabilities due to the inherent properties of steel, which include high melting points and low thermal conductivity. In many cases, steel structures can achieve fire resistance ratings of up to 2 hours or more, providing sufficient time for evacuation and firefighting activities in the event of a fire.

- Q: How are steel structures designed to accommodate architectural lighting and electrical systems?

- Steel structures are designed to accommodate architectural lighting and electrical systems in a number of ways. Firstly, the structural engineers work closely with the architects and electrical engineers to understand the specific requirements of the lighting and electrical systems. One important consideration is the load-bearing capacity of the steel structure. Electrical systems and lighting fixtures can be heavy, so the structural engineers must ensure that the structure is designed to support these additional loads. This involves calculating the maximum loads that will be imposed on the structure and designing the steel members and connections accordingly. Another consideration is the placement of the lighting fixtures and electrical outlets. The structural engineers must work with the architects to determine the optimal locations for these elements, taking into account factors such as aesthetic preferences, functionality, and safety. This may involve integrating lighting fixtures into the steel structure itself, such as recessing them into beams or columns. Additionally, the structural engineers must coordinate with the electrical engineers to ensure that the necessary conduits and wiring can be installed within the steel structure. This may involve integrating cable trays, raceways, or other electrical infrastructure into the design of the steel members. Finally, the steel structure must be designed to accommodate any necessary control systems for the lighting and electrical systems. This may involve providing space for control panels, switches, or other equipment. Overall, designing steel structures to accommodate architectural lighting and electrical systems requires close collaboration between structural engineers, architects, and electrical engineers. The goal is to create a structure that is not only visually appealing but also functional, safe, and able to support the specific requirements of the lighting and electrical systems.

- Q: How are steel structures designed to withstand snow loads?

- The strength and stability of steel structures are ensured by a combination of factors when it comes to withstanding snow loads. First and foremost, the design of the steel structure takes into consideration the expected snow loads in the specific location where it will be erected. This involves assessing factors such as the intensity, duration, and wind speed and direction, which can impact how the snow is distributed on the structure. Moreover, engineers employ specific design codes and standards that outline the minimum requirements for snow load design. These codes offer guidance on determining the magnitude of the snow load that the structure should be designed to handle. For instance, in the United States, the International Building Code (IBC) specifies snow load requirements based on the structure's importance and the snow load zone of the location. Once the snow load requirements are established, engineers utilize various load combinations and design methods to calculate the forces exerted by the snow load on the structure. This includes taking into account the weight of the snow itself, as well as any potential impact or drift effects caused by wind or other factors. These calculations aid in determining the necessary strength and stability of the structure to resist the snow loads. To further enhance the ability of the steel structure to withstand snow loads, engineers may incorporate additional design elements such as the slope and pitch of the roof, which facilitate the easy shedding of snow. They may also include features like snow guards or snow fences to prevent excessive snow accumulation in specific areas of the structure. In summary, ensuring the ability of steel structures to withstand snow loads involves a thorough analysis of the expected snow loads, adherence to design codes and standards, and implementation of appropriate design features. This guarantees that the structure can safely support the weight of the snow and maintain its structural integrity under varying snow load conditions.

Send your message to us

Steel flat bar steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords