Steel Cold Rolled Deformed Bar For Container

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

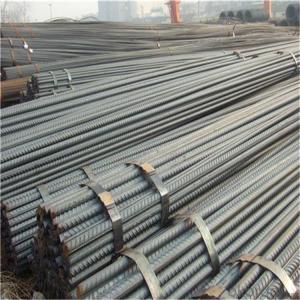

Specifications of Steel Cold Rolled Deformed Bar For Container

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Chemical Composition of Steel Cold Rolled Deformed Bar For Container

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Usage and Applications of Steel Cold Rolled Deformed Bar For Container

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Steel Cold Rolled Deformed Bar For Container

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the guidelines for preventing steel rebars from rusting during construction?

- To prevent steel rebars from rusting during construction, there are several guidelines that can be followed. These include: 1. Proper storage: Steel rebars should be stored in a dry and covered area to protect them from moisture. They should be kept off the ground and away from any sources of water, such as puddles or wet concrete. 2. Surface preparation: Before installation, rebars should be inspected for any signs of rust or corrosion. If any are found, they should be cleaned using a wire brush or sandblasting to remove the rust and create a clean surface for proper adhesion. 3. Coating: Applying a protective coating to the rebars can help prevent rusting. This can be done using epoxy, zinc, or other anti-corrosion coatings. The coating should be applied evenly and in accordance with the manufacturer's instructions. 4. Proper spacing: When placing rebars in concrete, it is important to ensure that they are adequately spaced to allow for proper ventilation and prevent moisture from being trapped between them. The spacing should be as per the design specifications or as recommended by structural engineers. 5. Adequate concrete cover: The rebars should have an adequate concrete cover to protect them from moisture and corrosion. This cover thickness should be as per the design requirements and should be maintained during construction. 6. Proper curing: After installation, the concrete should be properly cured to ensure it reaches its maximum strength and durability. Proper curing methods, such as using curing compounds or covering the concrete with plastic sheeting, can help prevent moisture penetration and rusting of the rebars. 7. Regular inspections: Regular inspections of the rebars should be conducted during construction to identify any signs of rust or corrosion. If any are found, appropriate measures should be taken to address the issue promptly and prevent further damage. By following these guidelines, construction professionals can minimize the risk of steel rebars rusting during construction, ensuring the structural integrity and longevity of the project.

- Q: Are steel rebars resistant to chemicals?

- Yes, steel rebars are generally resistant to chemicals. Steel is known for its high strength and durability, and it can withstand exposure to various chemicals without significant deterioration. However, the level of resistance may vary depending on the specific chemical and the concentration or duration of exposure. In general, steel rebars are highly resistant to common chemicals found in construction materials and environments, such as water, concrete additives, and standard cleaning agents. They are also resistant to many acids, alkalis, and organic solvents. However, some aggressive chemicals like strong acids or oxidizing agents may cause corrosion or damage to steel rebars over time. Therefore, it is important to consider the specific chemical environment when selecting and using steel rebars, and take appropriate measures to protect them if necessary, such as using protective coatings or corrosion inhibitors.

- Q: Can steel rebars be used in structures with high carbonation levels in concrete?

- No, steel rebars should not be used in structures with high carbonation levels in concrete as the carbonation process can lead to corrosion of the steel, compromising the structural integrity of the building.

- Q: What are the different types of steel rebars used in industrial constructions?

- There are several different types of steel rebars that are commonly used in industrial constructions. These rebars are essential for reinforcing concrete structures and providing strength and durability to the overall construction. Some of the main types of steel rebars used in industrial constructions include: 1. Mild Steel Rebars: Also known as black steel rebars, these are the most commonly used type of rebars in construction. They are made from carbon steel and have a smooth surface. Mild steel rebars provide adequate strength and are cost-effective, making them suitable for a wide range of industrial applications. 2. High-strength Deformed Steel Rebars (HSD): These rebars have ribs or deformations on their surface to provide better bonding with concrete. HSD rebars are made from carbon steel and undergo a process called thermomechanical treatment to increase their strength. These rebars are commonly used in heavy-duty industrial constructions where higher strength is required. 3. Epoxy-coated Rebars: These rebars are coated with an epoxy resin to protect them from corrosion. Epoxy-coated rebars are commonly used in areas where the concrete is exposed to moisture or chemicals, such as bridges and marine structures. The epoxy coating acts as a barrier, preventing corrosion and extending the lifespan of the structure. 4. Galvanized Rebars: Galvanized rebars are coated with a layer of zinc to provide corrosion resistance. The zinc coating acts as a sacrificial layer, protecting the steel rebars from rusting. These rebars are commonly used in areas where the concrete is exposed to harsh environmental conditions or in coastal regions where the risk of corrosion is high. 5. Stainless Steel Rebars: Stainless steel rebars are highly corrosion-resistant and are used in environments that require exceptional durability and resistance to corrosion. They are commonly used in industrial constructions that are exposed to aggressive chemicals, high humidity, or extreme temperatures. Each type of steel rebar has its own set of advantages and is suitable for different applications based on the specific requirements of the industrial construction project. It is important to carefully consider factors such as strength, corrosion resistance, and cost when selecting the appropriate type of steel rebar for a particular construction project.

- Q: What is the sign of steel rebar

- At present, China's iron and steel products implementation standards are national standards (GB, GB / T), industry standards (YB), local standards and enterprise standards

- Q: How are steel rebars tested for quality and compliance with standards?

- Steel rebars are tested for quality and compliance with standards through various methods. These include visual inspections, dimensional checks, and mechanical tests. Visual inspections involve examining the rebars for any surface defects, such as cracks or deformations. Dimensional checks ensure that the rebars meet the required size, length, and shape specifications. Mechanical tests are conducted to assess the rebars' tensile strength, yield strength, elongation, and other mechanical properties. These tests involve subjecting the rebars to tension or bending to determine their ability to withstand loads and deformations. Compliance with standards is ensured by conducting these tests in accordance with established protocols and guidelines set by relevant regulatory bodies or organizations.

- Q: What are the different types of tests conducted on steel rebars for quality assurance?

- There are several types of tests conducted on steel rebars for quality assurance. Some common tests include tensile testing, bend testing, impact testing, hardness testing, and chemical composition analysis. These tests help ensure that the rebars meet the required mechanical properties, dimensional tolerances, and chemical composition standards, ensuring their quality and suitability for various construction applications.

- Q: What are the main properties of steel rebars?

- Steel rebars, also referred to as reinforcing bars, play a vital role in reinforced concrete structures due to their numerous advantageous characteristics. Firstly, steel rebars possess a high tensile strength, which enables them to withstand substantial pulling forces and effectively reinforce concrete to prevent cracking and structural failure. Secondly, steel rebars exhibit exceptional ductility, meaning they can deform under stress without fracturing. This flexibility allows them to absorb energy during seismic events or extreme loads, enhancing the overall performance and resilience of the reinforced concrete. Moreover, steel rebars are manufactured with a protective layer, such as epoxy or galvanized coating, to ensure corrosion resistance. This property is crucial as exposure to moisture, chloride ions, and other corrosive elements can significantly weaken the rebars and compromise the structural integrity. In addition, steel rebars can be easily welded together, facilitating efficient and effective construction. This feature enables the rebars to be connected seamlessly, forming a continuous and robust reinforcement network that enhances the overall strength and stability of the concrete structure. Furthermore, steel rebars possess thermal compatibility with concrete, meaning they have similar expansion and contraction properties. This characteristic minimizes the risk of cracking or structural damage caused by temperature changes, ensuring the long-term durability and stability of reinforced concrete structures. Lastly, steel rebars are widely available and relatively cost-effective compared to alternative reinforcing materials. This affordability, combined with their exceptional mechanical properties, makes them a popular choice for structural reinforcement in various construction projects. In conclusion, steel rebars offer high tensile strength, ductility, corrosion resistance, weldability, thermal compatibility, and cost-effectiveness. These properties are indispensable for providing structural strength and durability to reinforced concrete structures.

- Q: How do steel rebars prevent the concrete from cracking under tension?

- Steel rebars prevent concrete from cracking under tension by providing reinforcement and increasing the structural integrity of the concrete. When concrete is subjected to tensile forces, it tends to crack due to its low tensile strength. However, when steel rebars are embedded within the concrete, they act as a reinforcement by absorbing and distributing the tensile forces. The steel rebars, which are typically made of high-strength steel, have a much higher tensile strength compared to concrete. This means that when the concrete is subjected to tension, the rebars bear most of the load, preventing the concrete from cracking. The rebars act as a framework or skeleton within the concrete, resisting the tensile forces and ensuring the structural stability of the concrete. Moreover, the bond between the steel rebar and the concrete also contributes to preventing cracking under tension. The ribbed or deformed surface of the rebars enhances the bond with the surrounding concrete, creating a strong connection. This bond allows the rebars to transfer the tensile forces to the concrete matrix more effectively, reducing the risk of cracking. By reinforcing the concrete, steel rebars help to distribute the tensile forces more evenly throughout the structure. This prevents localized stress concentrations and minimizes the chances of cracks forming. Additionally, the presence of rebars can also help control crack propagation if cracks do occur, as they act as barriers that restrict the cracks from spreading further. In summary, steel rebars prevent concrete from cracking under tension by providing reinforcement and increasing the overall strength of the concrete structure. They bear the tensile forces, distribute them evenly, and enhance the bond between the rebar and the concrete. This reinforcement ensures the structural integrity of the concrete and helps prevent cracking.

- Q: How do steel rebars affect the cost of a construction project?

- Steel rebars can significantly affect the cost of a construction project because they are a crucial component in reinforced concrete structures. The cost of steel rebars depends on their quantity, grade, and size, and it can greatly impact the overall project budget. Additionally, the transportation and installation costs associated with steel rebars should also be taken into account. Therefore, careful planning and consideration of the type and amount of steel rebars required are essential to manage and optimize the project's cost.

Send your message to us

Steel Cold Rolled Deformed Bar For Container

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords