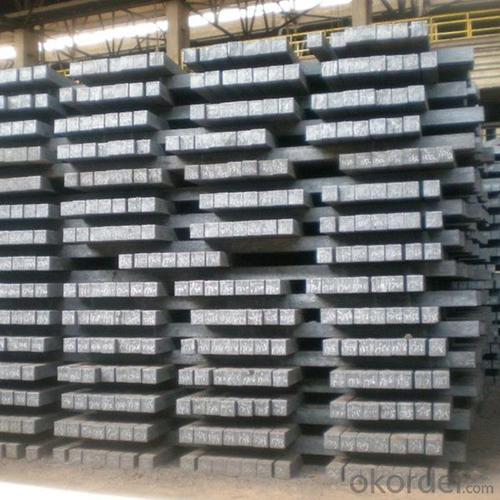

steel billets, square steel bar, mild steel bar China manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel billets, square steel bar, mild steel bar China manufacturer

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195/215/235/345/45#/3SP/5SP,ect

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and

various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like

Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Steel billets, mild steel bar chemical properties

| Ladle Analysis: | ||

| Designation | Carbon | Manganese |

| C15 | 0.12-0.18 | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.50 |

| C18 HMn | 0.15-0.21 | 1.00-1.50 |

| C20 HMn | 0.17-0.23 | 1.00-1.50 |

- Q: How are steel billets inspected for surface defects?

- Steel billets are inspected for surface defects using various methods and techniques to ensure the quality and integrity of the material. One common method is visual inspection, where trained inspectors carefully examine the surface of the billets for any visible defects such as cracks, scratches, pits, or uneven surfaces. They use proper lighting and magnification tools to thoroughly inspect the entire surface area. Another method used is dye penetrant testing. In this technique, a liquid dye is applied to the surface of the billets, which is then allowed to seep into any cracks or defects. After a specified time, excess dye is removed, and a developer is applied. The developer draws out the dye from any defects, making them clearly visible and easy to identify. Magnetic particle inspection is another widely used method. In this process, the billets are magnetized, and iron particles are applied to the surface. Any surface defects disrupt the magnetic field, causing the iron particles to gather around the defect, making them clearly visible upon inspection. This technique is particularly effective for detecting defects such as surface cracks. Ultrasonic testing is also commonly employed for inspecting steel billets. High-frequency sound waves are transmitted through the material, and any surface defects or internal flaws cause reflections or echoes. These reflections are detected and analyzed, providing information about the size, location, and type of defect present. Additionally, eddy current testing can be used to inspect steel billets for surface defects. This method involves passing an alternating current through a probe that is placed near the surface of the billet. Any defects or variations in the material's conductivity cause changes in the eddy currents, which can be detected and analyzed to identify surface defects. Overall, steel billets undergo meticulous inspection using a combination of visual, dye penetrant, magnetic particle, ultrasonic, and eddy current testing methods to ensure that any surface defects are identified and addressed, guaranteeing the quality and reliability of the final product.

- Q: What are the different shapes available for steel billets?

- Steel billets are manufactured in various shapes to cater to the diverse needs of different industries. Some of the available shapes for steel billets include: 1. Square Billets: These billets have equal sides, forming a square shape. They find extensive use in the construction industry for manufacturing beams, columns, and other structural components. 2. Round Billets: These billets have a circular cross-section and are commonly utilized in the production of seamless pipes, tubes, and rods. They are also employed in the automotive and aerospace sectors for manufacturing various components. 3. Rectangular Billets: These billets have unequal sides, forming a rectangular shape. They are frequently used in the construction industry to manufacture frames, window profiles, and other structural elements. 4. Hexagonal Billets: Hexagonal billets have six equal sides, forming a hexagon shape. They are commonly employed in the production of bolts, nuts, and other fasteners that require a hexagonal shape for proper fitting. 5. Octagonal Billets: Octagonal billets have eight equal sides, forming an octagon shape. They are often used in the manufacturing of special components and tools that require a unique shape for specific applications. 6. Slab Billets: Slab billets have a rectangular cross-section with a larger width compared to their height. They are primarily used for producing flat-rolled steel products such as sheets, plates, and coils. 7. Bloom Billets: Bloom billets have a square or rectangular cross-section with a larger size compared to regular billets. They are commonly utilized in the production of sections, bars, and rails. The choice of steel billet shape depends on the specific requirements of the desired end product and the manufacturing process involved. The versatility of steel billets makes them suitable for a wide range of applications in various industries.

- Q: What are steel billets?

- Steel billets are semi-finished metal products that are rectangular in shape and usually have a square cross-section. They are produced through a process called casting or continuous casting, where liquid steel is poured into molds and allowed to cool and solidify. Once cooled, the billets are typically hot-rolled or forged to give them their final shape and dimensions. Steel billets serve as a raw material for the production of various steel products, such as bars, rods, wires, and structural sections. They are commonly used in the construction industry for structural purposes, as well as in the manufacturing of automotive parts, pipes, and machinery. The quality of steel billets is crucial, as it directly affects the quality and performance of the final steel products. Therefore, they undergo rigorous quality checks and testing to ensure they meet the required standards for strength, durability, and other mechanical properties. Overall, steel billets play a vital role in the steel industry as a primary raw material for the production of a wide range of steel products, making them an essential component in various sectors of the economy.

- Q: What are the different types of steel billet shearing machines?

- In the market, one can find various steel billet shearing machines that are designed to meet specific needs and requirements. Below are some commonly used types: 1. The hydraulic billet shearing machine utilizes hydraulic power to cut steel billets with precision and efficiency. It has a high cutting force and can handle larger billet sizes. 2. Mechanical billet shearing machines use mechanical force, such as a flywheel or a cam-operated mechanism, to cut the steel billets. They are compact and suitable for smaller billet sizes. 3. Pneumatic billet shearing machines employ pneumatic pressure to shear the steel billets. They are commonly used when hydraulic or mechanical power is unavailable or unsuitable. 4. CNC billet shearing machines, controlled by computer numerical control, offer automated and precise cutting of steel billets. They can be programmed for complex cuts and are suitable for high-volume production environments. 5. Rotary billet shearing machines use a rotary blade to cut the steel billets. They provide continuous cutting motion and are ideal for larger billet sizes or long-length materials. 6. Cold billet shearing machines are specifically designed for cutting cold billets. They combine hydraulic or mechanical force and can handle more brittle materials when cold. 7. Hot billet shearing machines are designed to cut steel billets at high temperatures. They have specialized blades and cooling systems to manage the heat generated during the cutting process. These examples represent only a fraction of the steel billet shearing machines available in the market. The choice of machine depends on factors such as billet size, thickness, required precision, production volume, and specific application requirements. It is essential to consider these factors and seek guidance from professionals to determine the most suitable machine for individual needs.

- Q: How do steel billets compare to other types of metal billets?

- Steel billets possess several advantages over other types of metal billets. Firstly, the outstanding strength and durability of steel make it highly resistant to wear and tear, rendering steel billets suitable for a wide range of applications in the construction, automotive, and manufacturing industries. Furthermore, steel billets exhibit excellent heat resistance, enabling them to endure high temperatures without distorting or compromising their structural integrity. This quality makes steel billets perfect for the production of components that are subjected to extreme heat, such as engine parts or industrial machinery. Moreover, steel billets provide versatility in terms of shape and size. They can be effortlessly molded and formed into various configurations, empowering manufacturers to create intricate and complex designs. This adaptability makes steel billets the preferred choice in industries that necessitate customized or intricate parts. Additionally, steel billets boast high recyclability, making them an environmentally sustainable choice. The recycling process of steel requires significantly less energy compared to other metals, resulting in reduced carbon emissions and environmental impact. This aspect has led to an increased preference for steel billets in industries that prioritize sustainability and environmental responsibility. In conclusion, steel billets surpass other metal billets due to their exceptional strength, heat resistance, versatility, and recyclability. These qualities make steel billets the preferred choice for numerous industries, offering a combination of durability, functionality, and environmental sustainability.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- The main factors affecting the dimensional tolerances of steel billets include the quality of the raw material used, the manufacturing process employed, and the precision of the equipment and tools used during production. Additionally, environmental conditions such as temperature and humidity can also impact the dimensional tolerances of steel billets.

- Q: What are the main challenges in the marketing of steel billets?

- One of the main challenges in the marketing of steel billets is the highly competitive nature of the industry. There are numerous suppliers and manufacturers of steel billets globally, which creates a saturated market and makes it difficult for companies to differentiate their products and stand out from the competition. Additionally, fluctuations in steel prices and demand can impact the marketing efforts, as companies need to constantly adapt their strategies to changing market conditions. Another challenge is the need for extensive product knowledge and understanding of customer requirements, as steel billets are used in a wide range of industries with specific specifications and standards. Building strong relationships with customers and providing tailored solutions is crucial in overcoming these challenges and successfully marketing steel billets.

- Q: How do steel billets contribute to the manufacturing of sports equipment?

- Steel billets contribute to the manufacturing of sports equipment by providing a strong and durable material for various components. These billets are often used to create the frames, shafts, and other structural parts of sports equipment such as golf clubs, tennis rackets, and bicycles. The high strength and resilience of steel make it ideal for handling the rigorous demands of sports activities, ensuring that the equipment can withstand impact, vibrations, and repetitive use. Additionally, steel billets can be easily shaped and molded into different forms, allowing manufacturers to create customized designs that enhance performance and optimize weight distribution.

- Q: Difference between billet, slab and billet

- Production process of billet is through three methods: one is through the production of steelmaking and continuous casting equipment system, the molten steel is directly cast into the billet; two of steelmaking production systems of steel ingot or billet by rolling system of steel rolling equipment processing semi-finished products; three is the production of steelmaking system by forging semi-finished steel ingot the processing equipment. Market trends 1, domestic crude steel production remains high, although the domestic steel market has been relatively sluggish in recent times, and steel losses are more, but this does not seem to affect the enthusiasm of steel production. According to the China Steel Association statistics show that: in early April, the daily output of crude steel in key enterprises in China was 1 million 697 thousand and 300 tons, and the average daily output of crude steel in China was estimated at 2 million 123 thousand and 900 tons. And in mid April, crude steel daily output of ten days, although there has been a drop back, but still at a high level. According to statistics, in mid April, the average daily output of crude steel in key enterprises nationwide was 1 million 689 thousand and 100 tons, and the average daily output of crude steel in China was estimated at 2 million 115 thousand and 800 tons. Such a large production and sluggish demand in stark contrast, which is a drag on steel prices down one of the important factors.

- Q: What are the different types of rolling processes used for shaping steel billets?

- There are several different types of rolling processes used for shaping steel billets. Some of the commonly used processes include hot rolling, cold rolling, ring rolling, and skew rolling. Each process has its own advantages and is suitable for specific applications. Hot rolling involves heating the steel billet to a high temperature and then passing it through a series of rollers to shape it. Cold rolling, on the other hand, is performed at room temperature and is used to achieve tighter tolerances and improved surface finish. Ring rolling is used to produce seamless rings by gradually shaping the billet using a combination of axial and radial forces. Skew rolling is a specialized process used for producing balls or cylindrical shapes by rotating the billet at an angle to the rolling direction. Overall, these rolling processes offer various techniques to shape steel billets according to specific requirements.

Send your message to us

steel billets, square steel bar, mild steel bar China manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords