Steel Billet Steel Camshaft Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet Steel Camshaft Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

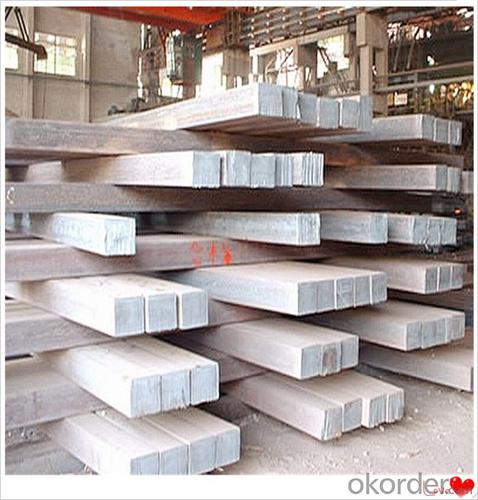

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

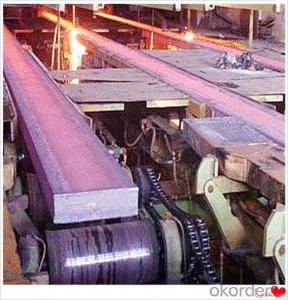

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

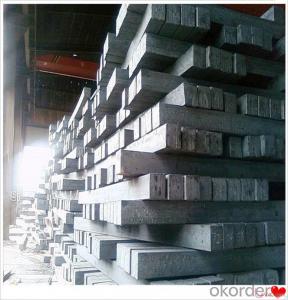

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

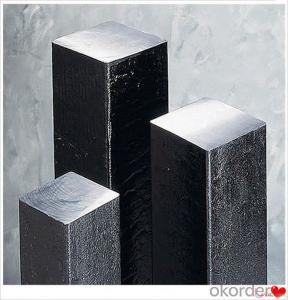

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the main factors affecting the dimensional accuracy of steel billets?

- The main factors affecting the dimensional accuracy of steel billets include the quality of the raw materials used, the temperature and cooling rate during the casting process, the design and condition of the casting equipment, and the skill and experience of the operators.

- Q: How are steel billets used in the manufacturing of storage tanks?

- Steel billets are used in the manufacturing of storage tanks as the primary raw material. These billets are heated and shaped into the desired form, typically through processes like rolling or extrusion. They provide the necessary strength and durability required for storage tanks to safely contain and store various liquids or gases.

- Q: How are steel billets unloaded at the destination?

- Steel billets are typically unloaded at the destination using various methods depending on the infrastructure and equipment available. One common method is the use of cranes or forklifts equipped with lifting attachments. These machines are capable of lifting and moving the heavy steel billets from the transport vehicle to the designated storage area or processing facility. In some cases, a specialized unloading facility such as a rail yard or port may be utilized. Here, cranes or gantry systems are often employed to efficiently transfer the steel billets from rail cars or shipping containers onto trucks or storage areas. This method allows for a more streamlined unloading process, especially when dealing with large quantities of steel billets. Another method that is sometimes used is the utilization of conveyor belts or rollers. This method is particularly effective when unloading steel billets from a container or truck where they are arranged in a row. The conveyor belt or roller system allows for a continuous unloading process, with the billets being moved along the conveyor to the desired location. Regardless of the method employed, safety precautions are always taken during the unloading process to ensure the well-being of workers and the prevention of any damage to the steel billets. This may include using proper lifting techniques, securing the billets during transportation, and wearing appropriate personal protective equipment. Overall, the unloading of steel billets at the destination requires careful planning, efficient machinery, and adherence to safety protocols to ensure a smooth and successful operation.

- Q: How are steel billets used in the production of construction machinery?

- Steel billets are used in the production of construction machinery as they serve as the raw material for forging and casting processes. These billets are heated, shaped, and molded into various components such as gears, axles, and frames, which are then assembled to create the construction machinery. The high strength and durability of steel make it an ideal material for construction machinery, ensuring the equipment can withstand heavy loads and harsh working conditions.

- Q: How are steel billets used in the production of shipbuilding components?

- Steel billets are commonly used in the production of shipbuilding components as a starting material. These billets are heated and then forged or rolled into various shapes and sizes, such as plates, beams, or angles, which are essential for constructing the structural framework of ships. The versatility and strength of steel billets make them ideal for withstanding the demanding conditions at sea, ensuring the durability and safety of shipbuilding components.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- The dimensional tolerances of steel billets can be influenced by various factors. One of the main factors is the manufacturing process itself. The method used to produce the billets, such as casting or hot rolling, can impact the final dimensions. For example, casting processes may introduce variations in the cooling rate, which can affect the overall shape and size of the billets. Another important factor is the initial quality of the raw material. The composition and homogeneity of the steel used to produce the billets can contribute to dimensional variations. Impurities or uneven distribution of alloying elements can lead to inconsistencies in the size and shape of the billets. The temperature during the manufacturing process is also a significant factor. High temperatures can cause thermal expansion, leading to dimensional changes in the billets. Cooling rates and control of the cooling process are critical to maintaining the desired tolerances. The design and condition of the equipment used in the manufacturing process can also impact the dimensional tolerances. Proper maintenance and calibration of machinery are essential to ensure consistent and accurate production. Finally, external factors such as handling and transportation can affect the dimensional tolerances of steel billets. Improper handling or rough transportation conditions can cause physical deformations or damage to the billets, leading to variations in their dimensions. Overall, the dimensional tolerances of steel billets are influenced by factors such as the manufacturing process, raw material quality, temperature control, equipment condition, and handling and transportation practices. Attention to these factors is crucial to achieving the desired dimensional accuracy in steel billets.

- Q: What are the different types of steel billet rolling defects?

- During the rolling process, various defects can arise in steel billets, which can have adverse effects on the final product's quality and integrity. The most commonly encountered types of steel billet rolling defects are as follows: 1. Surface cracks: These are minute cracks that manifest on the billet's surface. They can result from inadequate cooling or excessive rolling pressure. Surface cracks jeopardize the steel's strength and durability. 2. Center cracks: Inner core cracks occur when temperature control during the rolling process is incorrect. Center cracks can lead to structural weaknesses and reduced steel performance. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the billet's surface. It usually arises due to uneven or improper rolling pressure distribution. Scalloping negatively impacts the steel's appearance and surface quality. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can be caused by the presence of impurities or inclusions in the steel, as well as inadequate heating or rolling conditions. Lamination defects weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the billet's edges become uneven or distorted during rolling. This can be the result of improper alignment or uneven pressure distribution. Wavy edges affect the steel's dimensional accuracy and overall quality. 6. Surface defects: Surface defects encompass scratches, pits, or other imperfections on the billet's surface. They may occur due to insufficient cleaning or handling procedures, as well as improper rolling conditions. Surface defects impact the steel's appearance and surface quality. In conclusion, these steel billet rolling defects hold significant implications for the final product's quality, performance, and safety. Manufacturers must closely monitor the rolling process and implement appropriate quality control measures to minimize the occurrence of these defects.

- Q: What is the difference between steel billets and steel bars?

- Steel billets and steel bars are both raw forms of steel, but they differ in terms of their shapes and sizes. Steel billets are larger, rectangular-shaped semi-finished products that are typically used as input material for further processing, such as rolling or forging. On the other hand, steel bars are smaller, cylindrical-shaped finished products that have undergone additional processing, such as hot or cold rolling, to achieve a desired shape and size. In summary, steel billets are the starting point in the steel production process, while steel bars are the end products ready for use in various applications.

- Q: What is the role of steel billets in the manufacturing of hydraulic cylinders?

- Steel billets play a crucial role in the manufacturing of hydraulic cylinders as they are the raw material used to create the cylinder body. The billets are heated and then shaped into the desired cylindrical form through processes like hot rolling or forging. This allows for the production of strong and durable cylinders that can withstand high pressure and various operating conditions.

- Q: What are the main challenges in the handling of steel billets during production?

- The production of steel billets poses various challenges that must be addressed in order to achieve a streamlined and effective manufacturing process. Weight and size are major obstacles to consider when working with steel billets. These billets can be quite hefty, ranging from a few hundred kilograms to several tons, depending on their dimensions. As a result, lifting and moving them within the production facility can be difficult. The safe handling of these heavy loads necessitates the use of specialized equipment, such as cranes and forklifts. Another challenge lies in the potential for damage during the handling of steel billets. They are typically transported and stored in stacks or bundles, and improper handling techniques or inadequate protection can result in deformation, scratches, or even breakage of the billets. These damages can negatively impact the quality of the final product, leading to increased scrap rates and production costs. Furthermore, maintaining precise temperature control is crucial when working with steel billets. Steel is highly sensitive to temperature changes, and the billets must be kept within specific temperature ranges to prevent distortion or metallurgical issues. Careful attention must be paid when transferring billets between different areas of the production facility to ensure consistent temperatures. Proper inventory management and tracking also present challenges in the handling of billets. Steel billets are often stored in large warehouses or outdoor yards, and keeping track of their location, quantity, and quality can be complex. Efficient inventory management systems, such as barcoding or RFID tagging, are essential to minimize errors and facilitate the retrieval of the necessary billets for production. Lastly, safety is a significant concern when handling steel billets. The weight of the billets and the potential for injury make it imperative to adhere to strict safety protocols. Operators must receive proper training on the use of equipment, such as cranes and forklifts, and wear appropriate personal protective equipment (PPE) to prevent accidents or injuries. In conclusion, the handling of steel billets during production presents challenges related to weight, potential damage, temperature control, inventory management, and safety. Overcoming these challenges necessitates investments in specialized equipment, training, and efficient processes to ensure a smooth and successful production operation.

Send your message to us

Steel Billet Steel Camshaft Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords