Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

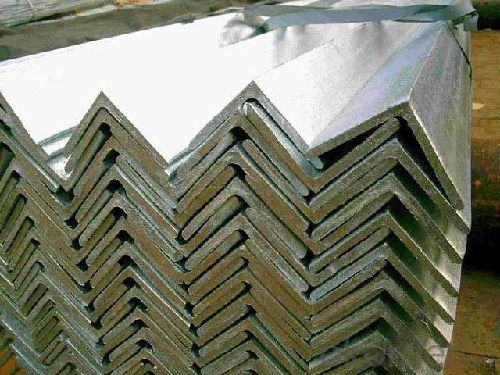

Product Description:

OKorder is offering Steel Angle Bar Middle Size at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Angle Bar Middle Size are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Angle Bar Middle Size are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel I-beams be used in railway infrastructure?

- Yes, steel I-beams can be used in railway infrastructure. They are commonly used as support structures for bridges, elevated platforms, and other railway infrastructure components due to their strength, durability, and ability to distribute weight efficiently.

- Q: Can steel I-beams be used for pedestrian bridges over rivers or canals?

- Yes, steel I-beams can be used for pedestrian bridges over rivers or canals. Steel I-beams are commonly used in bridge construction due to their strength, durability, and ability to span long distances. They provide excellent load-bearing capacity, making them suitable for pedestrian bridges that need to support the weight of people and other loads. Additionally, steel I-beams are resistant to corrosion, making them ideal for bridge structures exposed to water environments.

- Q: Can steel I-beams be used for architectural designs?

- Yes, steel I-beams can be used for architectural designs. Steel I-beams are known for their strength and durability, making them suitable for supporting heavy loads and creating large open spaces in architectural designs. They are commonly used in construction projects such as bridges, skyscrapers, and industrial buildings.

- Q: No. 10 I-beam for the main beam, 10 channel steel by the wall as auxiliary beam reinforcement, attic construction problems

- As the top, or building space of more than 4 meters high, double height or Deshang, commercial dual-use residential buildings like office space up to 4 meters above the building, as the LOFT reached the height of 4.8 meters, residential building gable top space is also very high, generally reach more than 4 meters to 4.2 meters, Deshang space can be made into the attic, like villa tiaogao double space, or high space thermocline can make a loft balcony, two layer, can be used in the above, storage, office, living, or shooting studio, loft is the best private space.

- Q: What are the different methods of connecting steel I-beams to other structural elements?

- There are several methods of connecting steel I-beams to other structural elements. Some common methods include welding, bolting, and using steel connectors. Welding involves joining the beams together using heat and a filler material, creating a strong and continuous connection. Bolting involves using bolts and nuts to secure the beams together, providing a flexible and adjustable connection. Steel connectors, such as plates and angles, are often used to connect I-beams to other elements, providing stability and support. The choice of connection method depends on factors such as the load requirements, structural design, and construction techniques.

- Q: How are steel I-beams supported during installation?

- Steel I-beams are typically supported during installation using temporary structures such as cranes or hoists. These devices are used to lift and position the beams into place, while additional support may be provided by temporary columns or braces until the beams are securely bolted or welded to the permanent structure.

- Q: Are steel I-beams resistant to rot or decay?

- Contrary to wood, steel I-beams do not possess resistance to rot or decay. This is due to the fact that steel does not absorb moisture, rendering it impervious to rotting or decaying. The utilization of steel I-beams in construction endeavors is primarily driven by their robustness and ability to withstand environmental elements. Specifically engineered to endure substantial loads and combat corrosion, these beams prove to be an enduring and dependable option for providing structural support.

- Q: What is the standard for No. 14 I-beam?

- I-steel whether ordinary or light, because the section size are relatively high and narrow, so the moment of inertia of section two of the spindle is larger, so it only can be directly used in the web plane bending member or the composition of lattice stress components. It is not suitable for the axial compression member or the bent member perpendicular to the web plane, which has great limitations in its application.H section steel is a kind of economical and economical surface profile (other cold bending thin wall steel, pressed steel plate, etc.). Because of the reasonable cross-section shape, they can make steel more effective and improve the bearing capacity. Unlike ordinary I-beam, the flange of H steel is widened, and the inner and outer surfaces are usually parallel so that it is easy to connect with high strength bolts and other components. The size of the series is reasonable, the model is complete, easy to design and use.

- Q: How are steel I-beams fire-rated?

- Steel I-beams can be fire-rated by applying a protective coating or by encasing them in fire-resistant materials. The purpose of fire rating steel I-beams is to enhance their ability to withstand the effects of fire for a certain period of time, allowing occupants to evacuate safely and giving firefighters enough time to extinguish the fire. One method of fire rating steel I-beams is to apply a fire-resistant coating or paint. These coatings are specifically designed to resist high temperatures and prevent the steel from reaching its critical temperature, which can cause structural failure. The coating forms an insulating barrier that slows down the transfer of heat to the steel, thus prolonging its structural integrity during a fire. Coatings can be either intumescent or cementitious, with intumescent coatings expanding and forming an insulating layer when exposed to high temperatures, and cementitious coatings providing a fire-resistant barrier. Another method is to encase the steel I-beams in fire-resistant materials, such as concrete or gypsum board. This is commonly done during the construction phase by creating fire-rated floor and wall assemblies. The steel I-beams are enclosed within the fire-resistant materials, creating a barrier that shields the steel from the heat of a fire. This method provides an additional layer of protection and enhances the fire resistance of the I-beams. The fire rating of steel I-beams is determined by various factors, including the thickness and type of fire-resistant coating used, the insulation properties of the coating, the duration for which the I-beams can resist fire, and the type of fire test the beams have undergone. Fire-rated steel I-beams are typically certified by testing laboratories according to recognized standards, such as UL (Underwriters Laboratories) or ASTM (American Society for Testing and Materials). It is important to note that fire rating does not make steel I-beams completely immune to fire damage. It only provides a certain level of fire resistance for a specific duration. Therefore, it is crucial to follow building codes and regulations, as well as regularly inspect and maintain fire-rated steel I-beams to ensure their effectiveness in fire scenarios.

- Q: What's the difference between I-beam and H steel? What's the weight of the same size?

- H type steel with flange width, and narrow distinction, respectively represented by HW, HM, HN and web and flange size, species diversity, such as HM500x300x11x15, on behalf of waist high 500mm, 11mm thickness, flange width 300mm, thickness 18mm, this is in fact the theory of value with the actual deviation will beIt's impossible to have the same sizes of I-beam and H.

Send your message to us

Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords