Stainless steel welded pipe variety specification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

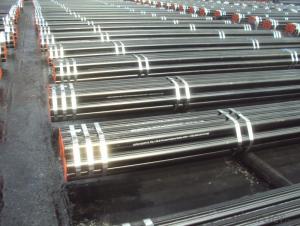

Stainless steel welded pipe is currently mainly used in heat exchanger tube, fluid pipe, pressure pipe, mechanical structure tube, city landscape, professions and so on

Welded steel pipe with high precision, uniform wall thickness, pipe inside and outside surface of high brightness (steel plate surface brightness surface level decision), can be arbitrary fixed length. Therefore, it reflects the economy and its aesthetics in high precision, low voltage applications in fluid.

| Name | 2 inch Stainless Steel Pipe,Welded Stainless Steel Pipe China Manufacture |

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23,40×20,50×20, 60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.25-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code down, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe |

- Q: What is the difference between 304N and 316N stainless steel pipes?

- The main difference between 304N and 316N stainless steel pipes lies in their composition and properties. 304N stainless steel is a variant of the 304 grade, which is one of the most commonly used stainless steel alloys. It contains a higher nitrogen content, which enhances its strength, corrosion resistance, and resistance to pitting and crevice corrosion. This makes it suitable for applications where higher strength and resistance to corrosion are required, such as in the chemical and petrochemical industries. On the other hand, 316N stainless steel is a variant of the 316 grade, which is known for its excellent corrosion resistance and high temperature strength. Similar to 304N, the addition of nitrogen in 316N stainless steel improves its strength and corrosion resistance. It also exhibits better resistance to pitting and crevice corrosion compared to 304N stainless steel. 316N stainless steel is commonly used in applications where superior corrosion resistance is necessary, such as in marine environments and medical equipment manufacturing. In summary, while both 304N and 316N stainless steel pipes offer improved strength and corrosion resistance compared to their non-N counterparts, 304N is more suitable for general-purpose applications where moderate corrosion resistance is required, while 316N is preferred for environments with higher levels of corrosion and in applications where superior resistance to pitting and crevice corrosion is necessary.

- Q: What are the temperature limits for stainless steel pipes?

- The temperature limits for stainless steel pipes can vary depending on the grade of stainless steel used. Generally, stainless steel pipes can withstand temperatures ranging from -150°C to 1100°C (-238°F to 2012°F). However, it is crucial to consider factors such as the specific stainless steel grade, the application, and any potential thermal expansion or contraction issues when determining the temperature limits for a particular stainless steel pipe.

- Q: Are stainless steel pipes suitable for industrial applications?

- Yes, stainless steel pipes are highly suitable for industrial applications. They possess excellent corrosion resistance, high strength, and durability, making them ideal for handling various fluids and gases in industrial settings. Additionally, stainless steel pipes can withstand high temperatures and pressure, making them reliable for demanding industrial processes.

- Q: Can stainless steel pipes be engraved?

- Yes, stainless steel pipes can be engraved. Engraving is a process that involves etching or carving designs, patterns, or text onto the surface of an object. Stainless steel is a versatile material that can be engraved using various methods, such as laser engraving, rotary engraving, or hand engraving. Laser engraving is particularly popular for stainless steel pipes as it provides precise and permanent markings. The engraved design or text can enhance the aesthetic appeal of the pipes and also serve functional purposes, such as identification or branding. However, it is important to note that the depth and quality of the engraving may vary depending on the type and grade of stainless steel used.

- Q: What are the different types of fittings used with stainless steel pipes?

- Stainless steel pipes can be paired with various types of fittings, depending on the specific needs and application. Here are some of the most commonly used fittings: 1. Compression fittings: These fittings create a tight, leak-proof connection by compressing a ferrule onto the pipe. They work well with both rigid and flexible stainless steel pipes and are easy to install. 2. Threaded fittings: Known as screwed fittings, these have female threads that can be screwed onto the male threads of the pipe. They are commonly used in low-pressure situations and can be easily installed or removed. 3. Butt weld fittings: These fittings are used to make a permanent, welded connection between two stainless steel pipes. The pipes need to be beveled to create a V-shaped groove, and they are typically used in high-pressure or high-temperature settings. 4. Flange fittings: Flanges are utilized to connect two stainless steel pipes or connect a pipe to a valve, pump, or other equipment. They provide a strong and leak-proof connection and can be bolted or welded onto the pipe. 5. Push-to-connect fittings: These fittings offer a quick and tool-free connection. They use a push-in mechanism to secure the pipe and are commonly used in plumbing and air compression systems. 6. Camlock fittings: Camlock fittings enable rapid connection and disconnection of hoses and pipes. They have a lever or cam mechanism that locks the fitting into place, ensuring a secure connection. These fittings are often used in industrial settings where frequent connections and disconnections are necessary. Ultimately, the choice of fitting depends on factors such as the application, pressure requirements, and ease of installation. It is crucial to select the appropriate fitting to guarantee a reliable and long-lasting connection for stainless steel pipes.

- Q: How do stainless steel pipes perform in corrosive environments?

- Stainless steel pipes excel in corrosive environments, owing to the presence of chromium in their composition. This imparts high resistance to corrosion and oxidation, making them ideal for applications where exposure to corrosive substances like acids, chemicals, and saltwater is common. The chromium in stainless steel creates a protective layer on the pipe's surface, known as the passive layer. This shield effectively prevents the underlying metal from being affected by corrosive elements. Consequently, stainless steel pipes can endure prolonged exposure to corrosive environments without degradation or loss of structural integrity. Moreover, stainless steel pipes exhibit excellent resistance to pitting corrosion. This occurs when localized damage to the passive layer leads to the formation of small pits or holes on the surface. This resistance further enhances their reliability and durability in corrosive environments. Additionally, stainless steel pipes possess other advantageous properties such as strength, durability, and high temperature resistance. These attributes contribute to their preference in industries like chemical processing, oil and gas, marine, wastewater treatment, and more. In summary, stainless steel pipes are renowned for their exceptional performance in corrosive environments. Their resistance to corrosion, pitting, and high temperatures, alongside their durability and strength, make them a dependable and cost-effective choice for applications requiring corrosion protection.

- Q: Can stainless steel pipes be used for nuclear power plants?

- Yes, stainless steel pipes can be used for nuclear power plants. Stainless steel is commonly used in nuclear power plants due to its excellent corrosion resistance, high strength, and heat resistance properties. It is suitable for transporting various fluids and gases within the plant, including coolant, steam, and chemicals. Additionally, stainless steel's durability and ability to withstand extreme conditions make it a reliable choice for nuclear power plant applications.

- Q: What are the different types of stainless steel pipe end connections?

- There are several different types of stainless steel pipe end connections, including threaded connections, socket weld connections, butt weld connections, flanged connections, and compression connections.

- Q: How do you clean and maintain stainless steel pipes?

- To clean and maintain stainless steel pipes, start by wiping them down with a mild detergent or soap and warm water using a soft cloth or sponge. Rinse thoroughly and dry with a clean cloth to prevent water spots. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Regularly inspect the pipes for any signs of corrosion, staining, or damage, and promptly address any issues to prevent further deterioration. Additionally, applying a stainless steel cleaner or polish can help remove stubborn stains and restore the shine of the pipes.

- Q: What are the cost considerations for stainless steel pipes?

- The cost considerations for stainless steel pipes include the initial purchase price, installation costs, maintenance expenses, and potential long-term savings due to their durability and corrosion resistance. Additionally, factors such as the grade, size, and quantity of pipes needed and any additional fabrication or customization requirements can also impact the overall cost.

Send your message to us

Stainless steel welded pipe variety specification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords