Stainless Steel Sheets Steel Plates 400 Series Made In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

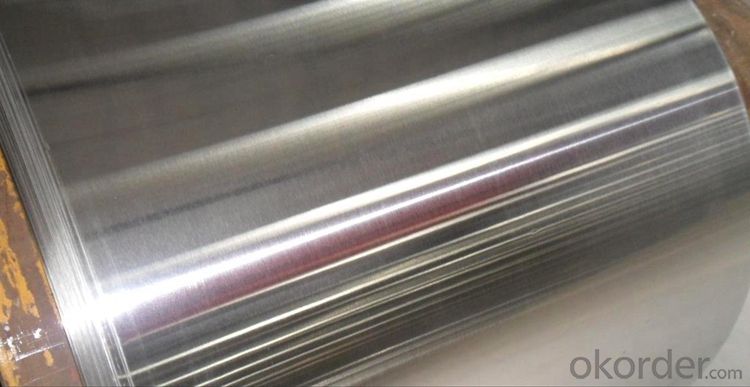

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Are stainless steel sheets resistant to pitting?

- Yes, stainless steel sheets are resistant to pitting. Stainless steel has a high resistance to corrosion, including pitting corrosion, due to its chromium content which forms a protective oxide layer on the surface. This makes stainless steel sheets a durable and reliable material for various applications where resistance to pitting is important.

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are highly suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh and corrosive environments, making it an ideal material for such applications. It can effectively handle the challenges posed by wastewater treatment plants, including exposure to chemicals, moisture, and high temperatures, while maintaining its structural integrity and preventing contamination.

- Q: What are the different surface patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of surface patterns that each have their own unique appeal and practical benefits. One popular choice is the brushed finish, achieved by using a fine abrasive material to brush the surface of the sheet. This creates an elegant pattern of parallel lines and gives the sheet a sophisticated appearance. Moreover, the brushed finish helps to conceal scratches and fingerprints, making it a practical option for applications where appearance matters. Another commonly used surface pattern is the mirror finish, attained by polishing the sheet to create a highly reflective and glossy surface. This finish is often preferred in architectural and decorative settings where a sleek and luxurious look is desired. Additionally, the mirror finish is easy to clean and maintain. Embossed or textured patterns are also available for stainless steel sheets. These patterns are created by stamping or rolling the sheet with a specific design, resulting in raised or recessed areas on the surface. This not only adds visual interest but also enhances grip and slip resistance, making it suitable for flooring or industrial equipment. Furthermore, there are perforated stainless steel sheets with small holes or slots in a specific pattern. These sheets are commonly used in architecture for decorative screens or facades, as well as for filtration or ventilation purposes. The perforations can be customized in various shapes and sizes to meet specific requirements. In conclusion, the choice of surface pattern for stainless steel sheets depends on the desired appearance, functionality, and application. Whether it's the sleek brushed or mirror finish, the textured embossed patterns, or the versatile perforated sheets, there is a wide range of options available to suit different needs.

- Q: How do you prevent distortion when welding stainless steel sheets?

- In order to prevent distortion while welding stainless steel sheets, it is important to follow several key steps and precautions: 1. Begin by ensuring that the stainless steel sheets are thoroughly cleaned and free from any contaminants, such as oil, grease, or dirt. Use an appropriate solvent or degreaser to clean the surfaces before welding. This will help to avoid trapping impurities in the weld, which can cause distortion. 2. Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Make sure that the edges of the sheets are properly aligned and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlling the heat input is essential to prevent excessive distortion. Use the appropriate welding technique, such as TIG or MIG, to control the heat. Avoid overheating the stainless steel sheets, as this can lead to warping and distortion. It is important to maintain a consistent and controlled heat input throughout the welding process. 4. Plan the weld sequence properly to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This will prevent localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help reduce distortion. 5. Choose the right welding technique and parameters. For example, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Consider preheating the stainless steel sheets to reduce the temperature gradient and minimize distortion. Ensure that the preheating temperature is within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements. Therefore, it is recommended to refer to the manufacturer's guidelines and seek professional advice for optimal results.

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel is known for its excellent weldability and can be easily welded using various welding processes such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas). It also offers good formability, allowing it to be fabricated into different shapes and structures with relative ease.

- Q: What is the maximum thickness of a stainless steel sheet?

- The maximum thickness of a stainless steel sheet can vary depending on the specific grade or type of stainless steel being used. In general, stainless steel sheets can range from as thin as 0.4 millimeters (0.0157 inches) to as thick as 100 millimeters (3.937 inches) or more. However, it is important to note that the availability of thicker sheets may be limited and can vary based on the supplier or manufacturer. Additionally, some stainless steel alloys may have different thickness limits due to their composition and intended use. Therefore, it is always recommended to consult with a supplier or refer to the specifications provided by the manufacturer to determine the maximum thickness of the specific stainless steel sheet you require.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Yes, stainless steel sheets can be used for wastewater treatment. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and corrosive elements often found in wastewater treatment processes. Additionally, its smooth surface makes it easy to clean and maintain, ensuring long-term durability and effectiveness in treating wastewater.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The common sizes and thicknesses of stainless steel sheets vary depending on the intended use and industry standards. However, there are some standard sizes and thicknesses that are commonly found in the market. For stainless steel sheets, the most common sizes range from 4x8 feet (1219x2438mm) to 5x10 feet (1524x3048mm). These sizes are widely available and are suitable for various applications such as construction, automotive, and fabrication. Regarding thickness, stainless steel sheets are available in a range of gauges, usually measured in inches or millimeters. The most common thicknesses for stainless steel sheets are 0.0276 inches (0.7mm), 0.0359 inches (0.91mm), 0.0478 inches (1.21mm), 0.0598 inches (1.52mm), 0.0747 inches (1.90mm), and 0.0897 inches (2.28mm). These thicknesses are frequently used in commercial and industrial applications. It is important to note that stainless steel sheets can be custom-made to meet specific requirements, including non-standard sizes and thicknesses. In such cases, it is advisable to consult with a supplier or manufacturer who can provide personalized solutions based on the specific needs of the project.

- Q: Can stainless steel sheets be used for pressure vessels?

- Yes, stainless steel sheets can be used for pressure vessels. Stainless steel is known for its excellent corrosion resistance, which makes it an ideal material for pressure vessels that are exposed to harsh environments or corrosive substances. It also has high strength and good mechanical properties, allowing it to withstand the internal pressure exerted by the fluid or gas inside the vessel. Additionally, stainless steel sheets can be easily formed and welded to create the desired shape and size of the pressure vessel. Overall, stainless steel sheets are a popular choice for pressure vessels in various industries such as oil and gas, chemical processing, and pharmaceuticals.

- Q: Can stainless steel sheets be cut or welded?

- Indeed, it is possible to cut and weld stainless steel sheets. Various methods, such as shearing, plasma cutting, laser cutting, or waterjet cutting, can be utilized to cut stainless steel sheets. When it comes to welding, the process involves joining two pieces together by heating them to their melting points and, if needed, incorporating a filler material. Nevertheless, it is crucial to acknowledge that welding stainless steel necessitates specific techniques and equipment due to its distinctive attributes, including low thermal conductivity and high thermal expansion. Consequently, it is imperative to possess adequate training and expertise to guarantee a fruitful and high-quality weld.

Send your message to us

Stainless Steel Sheets Steel Plates 400 Series Made In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords