Stainless Steel Coils 400 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

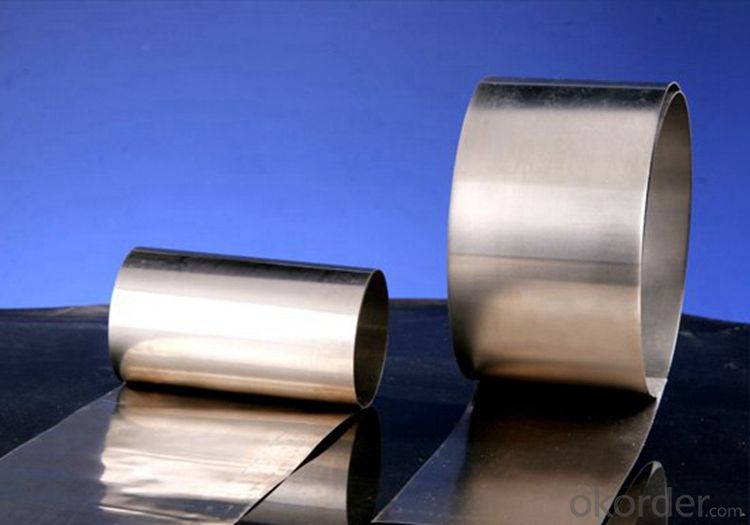

Detail picture for Stainless Steel Coils/Sheets

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How are stainless steel sheets installed?

- Stainless steel sheets are typically installed by first preparing the surface for installation, ensuring it is clean and free from any debris or contaminants. The sheets are then carefully measured and cut to fit the desired area. Once the sheets are ready, they are usually secured to the surface using various methods such as screws, adhesive, or welding, depending on the specific installation requirements. Proper alignment and a secure attachment are crucial for a successful installation of stainless steel sheets.

- Q: Can stainless steel sheets be used for elevator doors or panels?

- Yes, stainless steel sheets can be used for elevator doors or panels. Stainless steel is a common material used in elevator construction due to its durability, strength, and aesthetic appeal. It is resistant to corrosion, which is essential for elevator doors and panels that are exposed to various environmental conditions. Stainless steel sheets can be easily formed and fabricated to meet the specific design requirements of elevator doors and panels. Additionally, stainless steel is easy to clean and maintain, making it a popular choice for high-traffic areas like elevators.

- Q: What is the elongation of stainless steel sheets?

- When stainless steel sheets are subjected to tensile forces, their ability to stretch or deform without breaking is known as elongation. This property is measured as a percentage of the original length of the sheet that can be stretched before it fractures. The elongation of stainless steel sheets can vary depending on the grade of stainless steel and the way it is manufactured. In general, stainless steel sheets have a higher elongation compared to metals like carbon steel because they are more ductile. However, the specific elongation value can vary based on factors such as the grade, thickness, and tempering of the stainless steel sheet.

- Q: 904L stainless steel plate generally used in what industry is more?

- Super austenitic stainless steel (904L stainless steel) is a highly alloyed austenitic stainless steel carbon content is very low, in dilute sulphuric acid has good corrosion resistance for corrosion in harsh environmental conditions and design.

- Q: Which is better, stainless steel plate kitchen?

- According to the organizational structure of classification at room temperature, a martensitic, Austenitic, Ferritic and duplex stainless steel; according to the classification of the main chemical components, basically can be divided into chromium and chromium nickel stainless steel two systems; by use of minute nitric acid resistant stainless steel, stainless steel, stainless steel corrosion resistance to sulfuric acid and so on, according to the corrosion resistance the type can be divided into stainless steel pitting corrosion, stress corrosion resistant stainless steel, intergranular corrosion resistant stainless steel etc.;

- Q: Are stainless steel sheets resistant to scaling?

- Stainless steel sheets possess resistance against scaling. Scaling is the result of oxide layer formation on a material's surface when subjected to elevated temperatures. Stainless steel comprises a significant amount of chromium, which generates a protective chromium oxide layer when exposed to oxygen. This oxide layer acts as a barrier, halting any further oxidation or scaling of the stainless steel. In addition, the inclusion of alloying elements like nickel and molybdenum further strengthens the scaling resistance of stainless steel sheets. Consequently, stainless steel sheets exhibit a high degree of scaling resistance, rendering them suitable for utilization in high-temperature surroundings.

- Q: What is the maximum size of stainless steel sheets?

- The maximum size of stainless steel sheets can vary depending on the manufacturer and specific requirements, but commonly available sizes range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters).

- Q: Are stainless steel sheets environmentally friendly?

- Yes, stainless steel sheets are considered environmentally friendly. Stainless steel is a highly sustainable material that can be recycled indefinitely without losing its properties. It is non-toxic, durable, and resistant to corrosion, reducing the need for replacements and minimizing waste. Additionally, the production process of stainless steel sheets has a lower environmental impact compared to other materials, making it an eco-friendly choice.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of punched finishes, each with distinct qualities and advantages. Let's explore some of the most commonly used options: 1. Round Hole: This punched finish, which features evenly spaced round holes, is highly versatile and widely utilized. It enables effective airflow and visibility and finds applications in ventilation systems, decorative panels, and filters. 2. Square Hole: With a clean and contemporary appearance, the square hole punched finish is often chosen when a more geometric pattern is desired. It is commonly employed in architectural projects, screens, and fencing. 3. Slotted Hole: The slotted hole punched finish is characterized by elongated holes, providing larger openings for enhanced visibility or improved drainage. It finds uses in grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Offering an aesthetically pleasing pattern, the hexagonal hole punched finish showcases hexagon-shaped holes. It is commonly used in decorative applications like wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, stainless steel sheets can be customized with various decorative patterns, including personalized designs, logos, or intricate shapes. This allows for a unique and personalized touch in any project. When choosing a punched finish for stainless steel sheets, it is crucial to consider the specific requirements of the application, including aesthetics, functionality, and performance. Key factors to consider include hole size, open area percentage, strength, and corrosion resistance.

- Q: How do you determine the best grade of stainless steel sheet for a specific application?

- When determining the ideal stainless steel sheet grade for a particular application, various factors need to be taken into account. Firstly, one must assess the environmental conditions to which the sheet will be exposed, including temperature, humidity, and potential contact with corrosive substances. By doing so, the necessary level of corrosion resistance for the stainless steel can be determined. Secondly, the mechanical properties required for the application must be considered, including strength, hardness, and ductility. The intended use of the stainless steel sheet, whether it be for structural purposes or for a decorative application, will help determine the specific mechanical properties needed. Furthermore, the fabrication process and any subsequent treatments or finishes must be taken into consideration. Depending on their composition and characteristics, certain stainless steel grades may be more suitable for forming, welding, or machining. Additionally, it is important to consider the cost implications associated with different stainless steel grades. Higher grades often come with a higher price tag, so it is essential to balance the desired performance with the available budget. To determine the most suitable stainless steel sheet grade, it is recommended to seek advice from experts in the field, such as stainless steel suppliers or engineers specializing in materials selection. Their knowledge and experience can provide valuable guidance, considering the specific requirements of the application.

Send your message to us

Stainless Steel Coils 400 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords