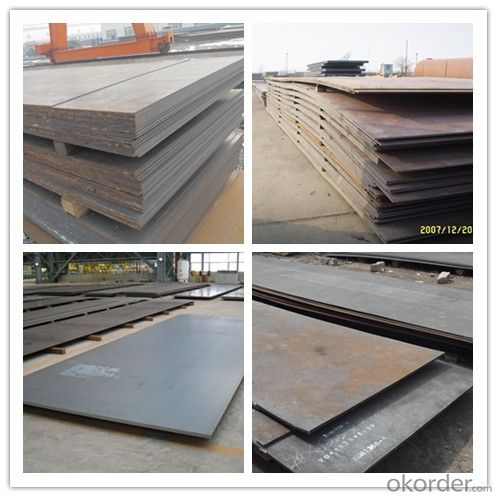

Hot Rolled Steel Sheets in Coils Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,DIN,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Oiled,Dry

Steel Grade:

Q195,Q215,Q235

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

according to weight

Net Weight:

23mt

Packaging:

Standard Export Packing

Hot Rolled Steel Sheet Plate Specifications:

1) Thickness: 1.5-75mm

2) Width: 1010-2500mm

3) Coil Weight: 1.7 - 10MT or as your request

4) Technical process: Steel Billet, Heated, Rolled, Coil

5) MOQ: 25mts

6) Payment terms: L/C OR TT

7) Uses: making pipes, cold strip-welded pipes, cold-bent shaped-steel, bicycle structures, small-sized press-pieces and household decoration goods

8) Sheet packed by box: 0.70-2.0mm x 1000mm x 2000mm

9) Each box weight: 3768kgs

HRC/ Hot Rolled Steel Coils:

| Material | Q195/Q235/ST12/ST13/ST14 |

| Standard | ASTM ;BS;JIS;DIN;GB |

| Inner Diameter | 508mm/610mm |

| Length | can be done as your requirements. |

| Thickness | 0.13mm-4.0mm (W.T tolerance ±1%) |

| Width | Strip:20-600mm |

| Coil weight | 3-5 tons |

| Surface | Oiled;Skin-passed;passivation |

| End | EC/EM |

| Technology | Cold rolled/annealing |

| Related products | Gi sheet |

| Usage | common structural parts and parts for drawing in engineering machines transportation machine construction machines, lifting machine, agricultural machines, light and civil industrial, household appliance industries. chemical equipments, drive casing pipe and light industrial civil industries. |

- Q: What are the different types of steel coil finishing equipment?

- Various industries utilize a range of steel coil finishing equipment to ensure that steel coils are properly prepared and finished according to the desired specifications. Some commonly used equipment includes: 1. Slitting lines, which cut large steel coils into narrower strips using multiple slitting knives at high speeds. These are commonly used in automotive, construction, and packaging industries. 2. Leveling lines, which flatten and straighten steel coils with uneven surfaces or irregularities using leveling rolls and tension control systems. These are commonly used in the manufacturing of appliances, furniture, and metal roofing. 3. Recoiling lines, which rewind steel coils into smaller coils of specific diameter and weight by carefully winding them around a mandrel. These are commonly used in electrical, HVAC, and steel distribution industries. 4. Cut-to-length lines, which cut steel coils into specific lengths as per customer requirements using precision measuring systems and hydraulic shears. These are commonly used in manufacturing, construction, and fabrication industries. 5. Coating lines, which apply protective coatings or finishes on steel coils to enhance corrosion resistance, durability, and appearance. These lines typically consist of cleaning and pre-treatment sections, followed by coating application sections. They are commonly used in automotive, appliances, and construction industries. These examples represent just a few of the available types of steel coil finishing equipment. Each type serves a specific purpose and plays a crucial role in the manufacturing and processing of steel coils for various applications.

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- Relatively cheap, strong, and non-toxic. For Carbon Steel alloys rust and corrosion are problems. For stainless alloys, cost becomes the problem [and corrosion is not eliminated]

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- In that video, he is using a steel-string acoustic guitar. However, when choosing between a nylon string guitar and a steel string guitar, you must consider a few things. Steel-string guitars are more painful in the beginning for the fretting hand, but that means you'll have more strength in your fingers faster. Nylon-string guitars are easier on the fingers and sound much smoother and calmer than steel-string guitars. Also, nylon-string guitars have a wider neck and that neck meets the body at the twelfth fret, while most steel-string guitars have a thinner neck that meets the body at the fourteenth fret. Have fun with your first guitar! :)

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q: Aluminum and Steel brittle or ductile based on these results? and why? Steel Aluminium% Elongation 0.2510.2705Modulus of E in ksi11833.33964.71Tensile Strength (ksi)87.5 51.5Yield Strength (ksi)78.5 41

- Only steel(of this pair)might be liable to brittle fracture,which would be implied by almost zero elongation or reduction in area at fracture.On this basis the steel has not failed by brittle fracture.I would expect much more elongation in pure aluminium than your sample shows so I presume it to be brittle unless it is an alloy rather than commercially pure aluminium.However brittle fracture in metals is a particular phenomenon to be determined by impact tests and examination of fracture surfaces and is particularly relevant to metals with the body centred crystal structure.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: steel strutural

- IS-2062-92 STEEL IS FOR GENERAL STRUCTURAL PURPOSES. Fe410 is the specification of IS2062-1999. For properties and for more , please click: stainless-steel.in/productspeci3....

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines where they are elongated and reduced in diameter to the desired thickness. The steel coils provide a continuous supply of raw material, ensuring a seamless production process for manufacturing wires of various sizes and applications.

- Q: I'm searching for the elastic modulus of ASTM A653 galvanized steel sheet. Max points for first person with a response that includes web address of reliable reference - I just haven't found it yet. thanks!

- Aluminum is non ferrous so a magnet won't persist with it, and this is softer than steel. once you have desperate that, if it has previous paint on it, this is particularly helpful to apply a primer that corresponds to the paint you would be utilising the two vinyl or oil based, then paint. this is possibly no longer Galvanized, yet whilst this is, the unpainted floor with have a 2 colour steel Spackle look.

- Q: My mother is in a weilding class, and today she accidentally welded Galvanized Steel. She doesn't feel good and she wants to know what the symptoms are for Galvanized Poisoning from breathing in the Fumes. Please help, I am worried for her.

- i have a dog with a galvanized chain on her neck ''for looks'' can she get even the slightest harmful effect from it being on her 24/7?

Send your message to us

Hot Rolled Steel Sheets in Coils Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords